UV photocuring glue applicable to electronic chip encapsulation

A light-curing adhesive and electronic chip technology, applied in adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problems of poor aging resistance and poor degradation resistance, and achieve good physical protection, Strong aging resistance and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

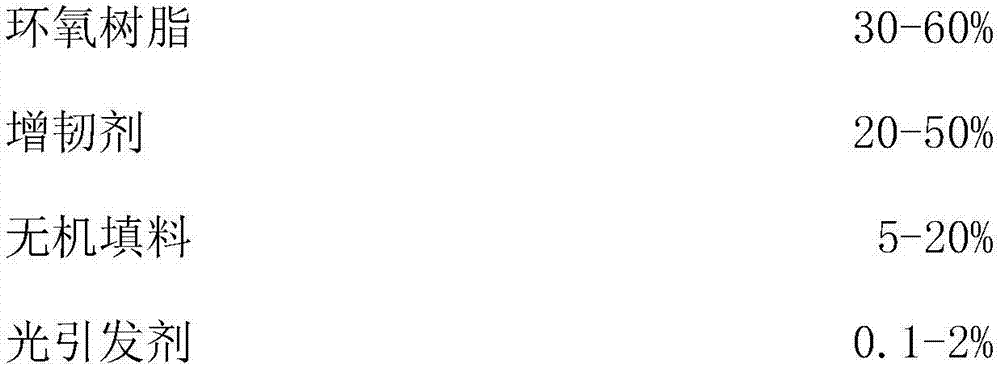

Method used

Image

Examples

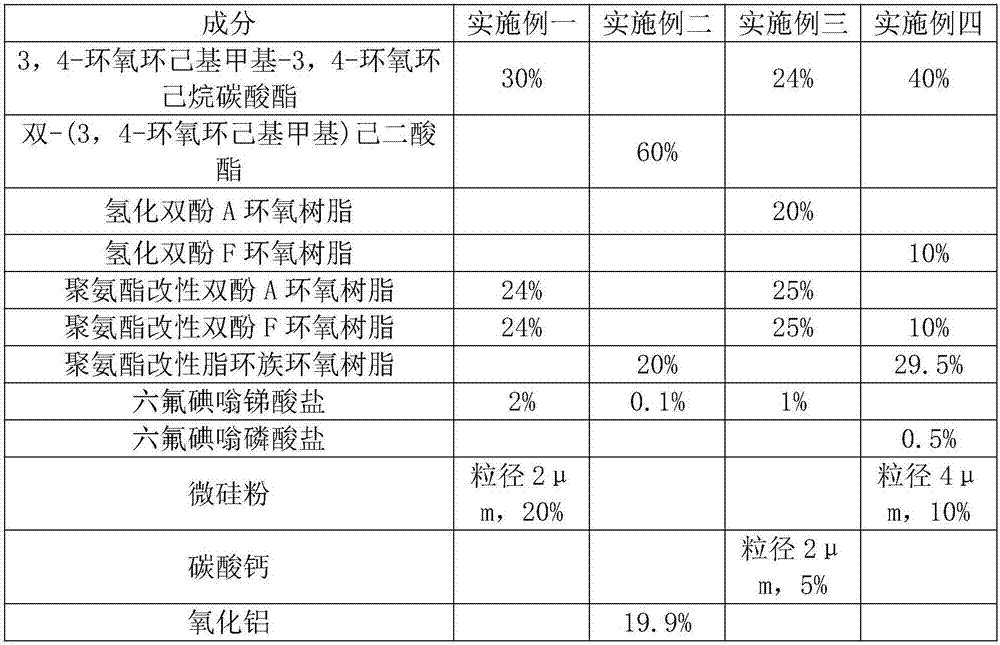

Embodiment 1

[0030] Example 1 After irradiating for 40 seconds, it changed from a liquid state to a solid state. The hardness of the cured product was measured to be 72D, the tensile strength was 28MPa, and the glass transition temperature was 55°C;

Embodiment 2

[0031] Example 2 After irradiating for 60s, it changed from a liquid state to a solid state, and the hardness of the cured product was determined to be 85D, the tensile strength was 32MPa, and the glass transition temperature was 68°C;

Embodiment 3

[0032] Example 3 After irradiating for 60s, it changed from a liquid state to a solid state. The hardness of the cured product was determined to be 82D, the tensile strength was 30MPa, and the glass transition temperature was 66°C;

[0033] Example 4 After irradiating for 45 seconds, it changed from a liquid state to a solid state. The hardness of the cured product was measured to be 76D, the tensile strength was 29MPa, and the glass transition temperature was 63°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com