Dimeric fatty acid-diglycidol ester modified amine hardener, preparation method and application

A technology of diglycidyl ester and dimer fatty acid, which is applied in the field of dimer fatty acid diglycidyl ester modified amine curing agent and its preparation, can solve the problems of poor toughening effect and insufficient impact resistance, and achieve stable operation and responsive The effect of short time and short alkali addition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

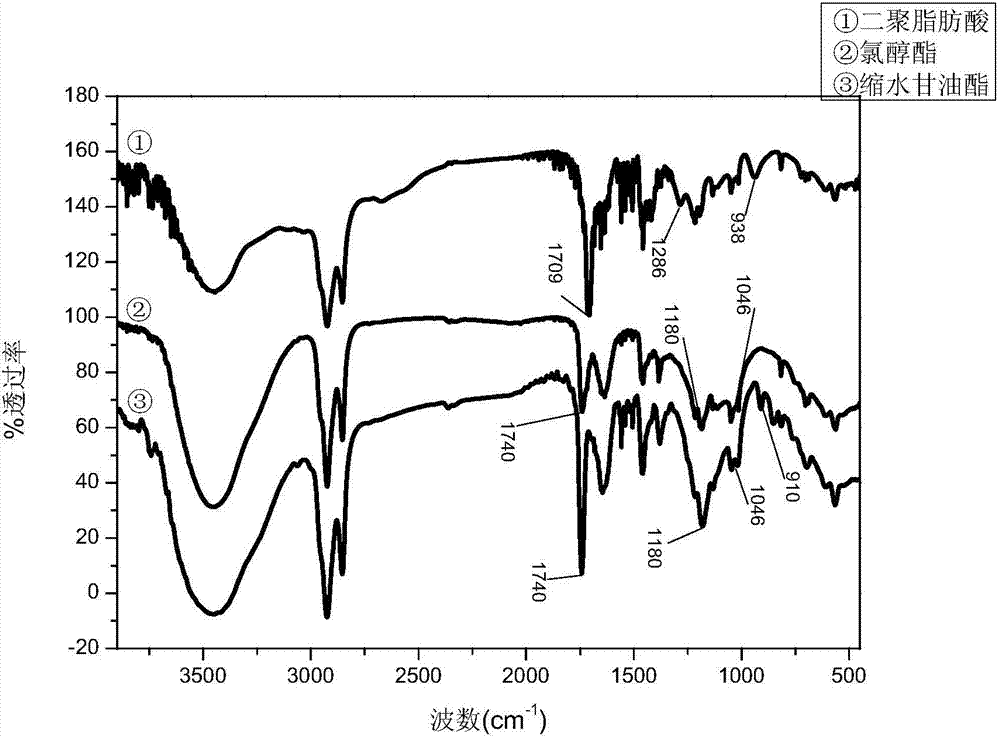

[0043] A dimer fatty acid diglycidyl ester modified amine curing agent is prepared by a method comprising the following steps:

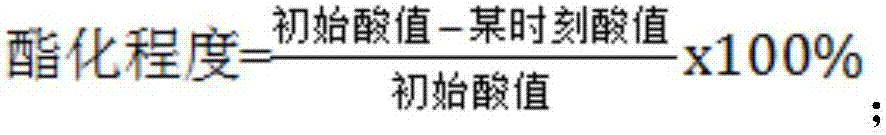

[0044] (1), esterification reaction

[0045] First add 112.00g of dimer fatty acid and 92.52g of epichlorohydrin into a four-neck flask equipped with stirring, nitrogen protection, thermometer and condenser, heat to 50°C and stir evenly, then add 2.24g of catalyst, stir for 10min and heat up to 100°C The esterification reaction was carried out at ℃ for 2.0h, and the obtained reaction solution 1 was the chlorohydrin ester intermediate;

[0046] The amount of the above-mentioned dimerized fatty acid and epichlorohydrin is calculated by molar ratio, dimerized fatty acid: epichlorohydrin is 1:5;

[0047] The catalyst is a quaternary phosphine salt, and the quaternary phosphine salt is tetrabutylphosphine chloride;

[0048] The consumption of catalyst is 2% of dimer fatty acid quality;

[0049] It has been determined that the acid value of the chlorohy...

Embodiment 2

[0070] A dimer fatty acid diglycidyl ester modified amine curing agent is prepared by a method comprising the following steps:

[0071] (1), esterification reaction

[0072] First, add 112.00g of dimer fatty acid and 129.53g of epichlorohydrin into a four-necked flask equipped with stirring, nitrogen protection, thermometer and condenser, heat to 50°C and stir evenly, then add 4.48g of catalyst, stir for 10 minutes and heat up to 80°C The esterification reaction was carried out at ℃ for 3.0 hours, and the obtained reaction solution 1 was the chlorohydrin ester intermediate;

[0073] The amount of the above-mentioned dimerized fatty acid and epichlorohydrin is calculated by molar ratio, dimerized fatty acid: epichlorohydrin is 1:7;

[0074] Described catalyst is tertiary amine, and described tertiary amine is triethylamine;

[0075] The consumption of catalyzer is 4% of dimer fatty acid quality;

[0076] It has been determined that the acid value of the chlorohydrin ester in...

Embodiment 3

[0092] A dimer fatty acid diglycidyl ester modified amine curing agent is prepared by a method comprising the following steps:

[0093] (1), esterification reaction

[0094] First add 112.00g of dimer fatty acid and 166.54g of epichlorohydrin into a four-necked flask equipped with stirring, nitrogen protection, thermometer and condenser, heat to 50°C and stir evenly, then add 1.12g of catalyst, stir for 10 minutes and heat up to 110°C °C for 1.5 hours of esterification reaction, the resulting reaction solution 1 is the chlorohydrin ester intermediate;

[0095] The amount of the above-mentioned dimerized fatty acid and epichlorohydrin is calculated by molar ratio, dimerized fatty acid: epichlorohydrin is 1:9;

[0096] The catalyst is a quaternary phosphonium salt, and the quaternary phosphonium salt is tetrabutylphosphine bromide;

[0097] The consumption of catalyst is 1% of dimerized fatty acid quality;

[0098] It has been determined that the acid value of the chlorohydri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com