Method for preparing chromium oxide green by using ferrochrome

A chrome oxide green and ferrochrome technology, which is applied to cells, electrolysis processes, electrolysis components, etc., can solve problems such as environmental pollution and land occupation, and achieve the effect of simplifying process equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

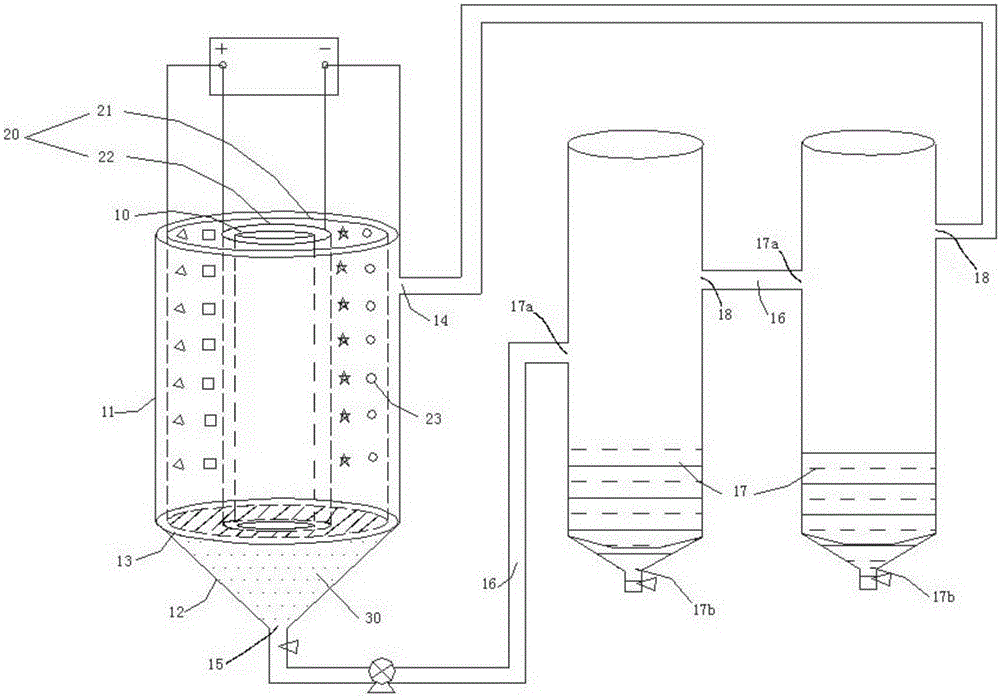

Image

Examples

Embodiment 1

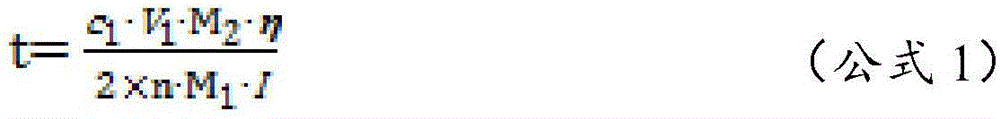

[0092] Embodiment 1: The high-concentration sodium chromate solution prepared by electrolysis with ferrochrome and sodium hydroxide electrolyte, separated and precipitated is the preparation raw material of chromium oxide green, and the high-concentration sodium chromate solution contains microparticle carbon, and the content of microparticle carbon About 1.0g / L~5g / L.

[0093] Take 500mL of sodium chromate with a concentration of 530g / L and a high-concentration sodium chromate electrolyte with a carbon content of about 5g / L as the raw material, react at 280°C and 8.2MPa for 6h, then terminate the hydrothermal reaction, and lower the temperature to room temperature A solid-liquid mixture slurry is obtained. It is subjected to solid-liquid separation, and the liquid phase obtains a pure chromate solution, and the solid phase obtains a solid phase of chromium hydroxide. The obtained chromium hydroxide solid phase was calcined at 1000°C for 2 hours in an air atmosphere, and then ...

Embodiment 2

[0094] Example 2: The preparation of chromium oxide green by the hydrothermal method is illustrated by taking ferrochromium and sodium hydroxide electrolyte electrolytically prepared high-concentration sodium chromate solution containing microparticle carbon as raw material and adding citric acid as reducing agent.

[0095](1) Take 61mL of sodium chromate electrolyte with a sodium chromate concentration of 263g / L as a raw material, add 8.4g of citric acid, and react at 200°C for 3 hours to terminate the hydrothermal reaction. When the temperature drops to room temperature, the solid-liquid Mix slurry. It is subjected to solid-liquid separation, and the liquid phase obtains a pure chromate solution, and the solid phase obtains a solid phase of chromium hydroxide. The obtained chromium hydroxide solid phase was calcined at 1000°C for 2 hours in an air atmosphere, and then the calcining reaction was terminated. After the temperature dropped to room temperature, the obtained solid...

Embodiment 3

[0097] Example 3: The preparation of chromium oxide green by hydrothermal method is illustrated by taking ferrochromium and sodium hydroxide electrolyte electrolytically prepared high-concentration sodium chromate solution containing microparticle carbon as raw material and adding carbon powder as reducing agent.

[0098] (1) Take 300mL of sodium chromate electrolyte with a concentration of 390g / L of sodium chromate as raw material, add 3.25g of carbon powder, react at 280°C for 3 hours, then terminate the hydrothermal reaction, and obtain a solid-liquid mixture when the temperature drops to room temperature Slurry. It is subjected to solid-liquid separation, and the liquid phase obtains a pure chromate solution, and the solid phase obtains a solid phase of chromium hydroxide. The obtained chromium hydroxide solid phase was calcined at 1000°C for 2 hours in an air atmosphere, and then the calcining reaction was terminated. After the temperature dropped to room temperature, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com