A kind of water-based nanometer four-color ink

A water-based and nano-technology, applied in the field of water-based four-color nano ink, water-based nano four-color ink, can solve the problems of not really eliminating VOC emissions, unfavorable industrial production, complex weaving process, etc., to achieve clear and complete images without diffusion and low cost , the effect of high color vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

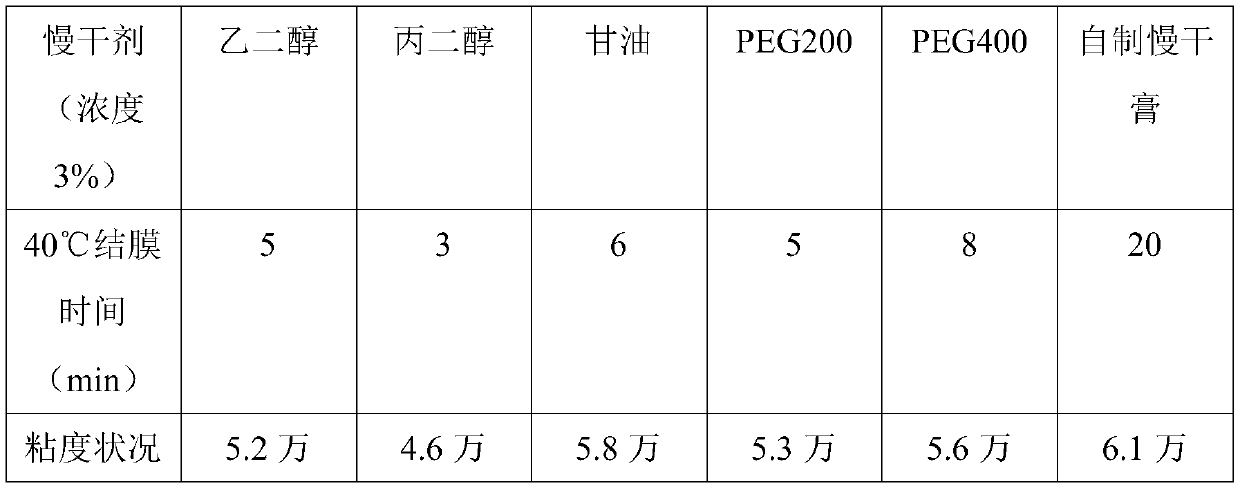

[0038] The preparation of slow-drying cream in the following each embodiment: add betaine and polyethylene glycol 400 molar ratio 3:2 in the reaction kettle containing solvent, at room temperature, add the aluminum trichloride of betaine quality 5% as The catalyst and a small amount of triethylamine are used as an acid-binding agent, and then the temperature is raised to 120°C, and the reaction is carried out for 2 hours, and the solvent is evaporated to obtain a crude product, which is separated and purified to obtain the main product of betaine-modified polyethylene glycol.

[0039] Raw material formula according to 1~4, the specific preparation method of the water-based nanometer four-color ink that is used for fabric and shoe material of the present invention is as follows: 1 / 3 water-based nano polycarbon type polyurethane resin, water-based surfactant, water-based disperse Put the agent and deionized water into the reaction kettle to disperse for 5 to 10 minutes, stir even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com