Synergistic Toughening of Polycrystalline Cubic Boron Nitride with Three Dimensions Materials

A technology of cubic boron nitride and polycrystalline cubic, which is applied in the field of preparation of synergistically toughened polycrystalline cubic boron nitride with three-dimensional materials, can solve the problems of high requirements for auxiliary materials and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing synergistically toughened polycrystalline cubic boron nitride with three-dimensional materials of the present invention comprises the following steps:

[0017] (1) Carry out surface high-energy treatment of cubic boron nitride powder, the equipment is a high-energy ball mill, the material of the ball mill is tungsten carbide, the material of the ball is high-density cemented carbide, the rotor speed is 580 rpm, and the ball milling time is 15 hours. Material: ball = 1:17, boiled with acid to disperse;

[0018] (2) Treat the obtained cubic boron nitride powder, zero-dimensional zirconia powder, one-dimensional silicon nitride whisker and two-dimensional graphene material by mass percentage 98.7~99.2%: 0.2~0.4%: 0.1~0.3% : 0.3 ~ 0.6% weighing, put into planetary ball mill for uniform refinement, material: ball = 1: 6 ~ 9;

[0019] (3) Dry the powder, put it into a spark plasma sintering furnace and sinter it into a shape. The sintering temperature ...

Embodiment 1

[0022] (1) Carry out surface high-energy treatment of cubic boron nitride powder, the equipment is a high-energy ball mill, the material of the ball mill is tungsten carbide, the material of the ball is high-density cemented carbide, the rotor speed is 580 rpm, and the ball milling time is 15 hours. Material: ball = 1:17, boiled with acid to disperse;

[0023] (2) Weigh the cubic boron nitride powder, zero-dimensional zirconia powder, one-dimensional silicon nitride whisker and two-dimensional graphene material by mass percentage of 99.2%: 0.2%: 0.1%: 0.5%, Put it into a planetary ball mill and refine it evenly, material: ball = 1:9;

[0024] (3) Dry the powder and put it into a spark plasma sintering furnace to sinter and shape it. The sintering temperature is 1380°C, heat preservation for 5 minutes, the heating rate is 900°C / min, and the cooling rate is 50°C / min to obtain a polycrystalline cubic boron nitride material.

Embodiment 2

[0026] (1) Carry out surface high-energy treatment of cubic boron nitride powder, the equipment is a high-energy ball mill, the material of the ball mill is tungsten carbide, the material of the ball is high-density cemented carbide, the rotor speed is 580 rpm, and the ball milling time is 15 hours. Material: ball = 1:17, boiled with acid to disperse;

[0027] (2) Weigh the cubic boron nitride powder, zero-dimensional zirconia powder, one-dimensional silicon nitride whisker and two-dimensional graphene material by mass percentage 99%: 0.4%: 0.2%: 0.4% of the obtained cubic boron nitride powder, Put it into a planetary ball mill and refine it evenly, material: ball = 1:8;

[0028] (3) Dry the powder and put it into a spark plasma sintering furnace to sinter and shape it. The sintering temperature is 1450°C, heat preservation for 3 minutes, the heating rate is 900°C / min, and the cooling rate is 50°C / min to obtain polycrystalline cubic boron nitride material.

PUM

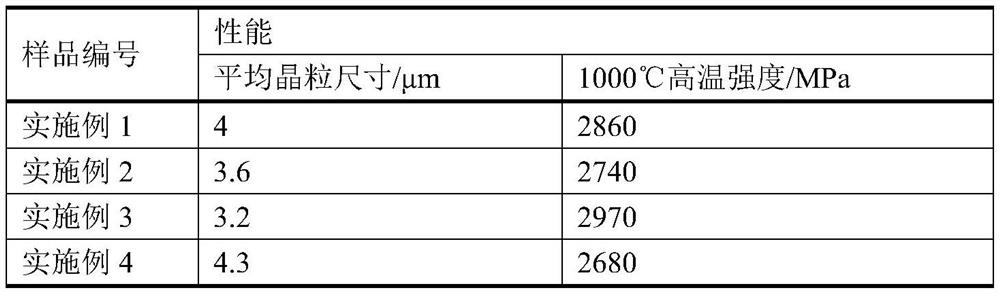

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com