Preparation method for modified graphene oxide adsorption material

A technology of adsorption materials and oxidized stones, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes. It can solve the problems of high condition requirements and long reaction cycle, and achieve uniform distribution of pore channels and excellent adsorption performance. , The effect of enhancing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

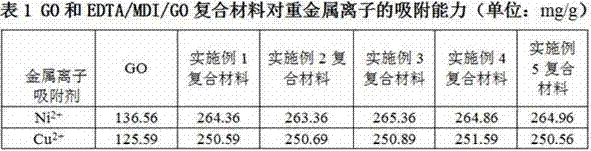

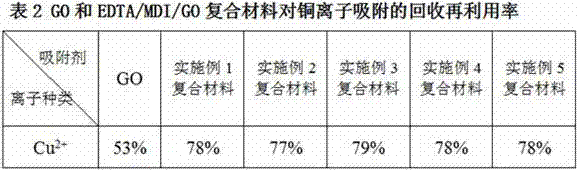

Examples

Embodiment 1

[0015] This embodiment includes the following steps:

[0016] (1) Take 100 mg of graphene oxide (commercially available) in a three-neck round bottom flask, add 50 mL of anhydrous DMF to ultrasonically disperse for 1 h, add 1 mL of MDI, and stir at 60 °C for 4 h; cool down after the reaction, and the reaction product Washing with anhydrous DMF for 3 times (using 15 ml of anhydrous N,N-dimethylformamide each time), centrifuging, and vacuum drying to obtain diphenylmethane diisocyanate functionalized graphene oxide;

[0017] (2) Take 0.1 g of diphenylmethane diisocyanate functionalized graphene oxide obtained in step (1) and 2 g of EDTA, grind and mix them evenly in an agate mortar, then place them in a ball mill, control the ratio of ball to material to 3:1, and the speed is 60rad / min, ball milling for 6h, washing with a sodium bicarbonate (NaHCO3) solution with a pH of 8.0 until no bubbles emerge, and then freeze-drying to obtain EDTA / diphenylmethane diisocyanate / graphene oxid...

Embodiment 2

[0019] This embodiment includes the following steps:

[0020] (1) Take 100 mg of graphene oxide (commercially available) in a three-neck round bottom flask, add 50 mL of anhydrous DMF for ultrasonic dispersion for 1 h, add 3 mL of MDI, and stir for 4 h at 60 °C; The product was washed 3 times with anhydrous DMF (15 ml of anhydrous N,N-dimethylformamide each time), centrifuged, and vacuum-dried to obtain diphenylmethane diisocyanate functionalized graphene oxide;

[0021] (2) Grind 0.1 g of diphenylmethane diisocyanate functionalized graphene oxide obtained in step (1) and 4 g of EDTA in an agate mortar, mix them uniformly and place them in a ball mill, control the ratio of ball to material to 3:1, and the speed is 60rad / min, ball milled for 6h, washed with a sodium bicarbonate (NaHCO3) solution with a pH of 8.0 until no bubbles emerged, and then freeze-dried to obtain an EDTA / MDI / graphene oxide composite material.

Embodiment 3

[0023] This embodiment includes the following steps:

[0024] (1) Take 100 mg of graphene oxide (commercially available) and place it in a three-neck round bottom flask, add 50 mL of anhydrous DMF for ultrasonic dispersion for 1 h, add 3 mL of MDI, and stir at 80 ° C for 2 h; after the reaction is completed, cool the reaction product Wash 3 times with anhydrous N,N-dimethylformamide (DMF) (15 ml of anhydrous N,N-dimethylformamide each time), centrifuge and dry in vacuo to obtain diphenylmethane di Isocyanate functionalized graphene oxide;

[0025] (2) Take 0.1 g of diphenylmethane diisocyanate functionalized graphene oxide obtained in step (1) and 2 g of EDTA, grind and mix them evenly in an agate mortar, and then place them in a ball mill, controlling the ratio of ball to material to 3:1, and the speed is 100rad / min, ball milled for 3 hours, washed with a sodium bicarbonate (NaHCO3) solution with a pH of 8.0 until no bubbles emerged, and then freeze-dried to obtain EDTA / MDI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com