Metal-ceramic concrete with high impact resistance at ultra-high temperature

A cermet and concrete technology, applied in the field of cermet concrete, can solve the problems of poor high-temperature ablation resistance and strength decline, and achieve the effects of high compressive strength, reduced internal expansion, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

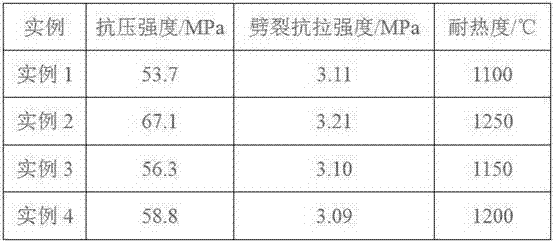

Embodiment 1

[0037] Each cubic meter of cermet concrete contains 500kg of cementitious materials (including 380kg of cement and 120kg of bauxite), 950kg of cermet coarse aggregate, 715kg of quartz sand fine aggregate, 180kg of water, and 7kg of polycarboxylic acid high-performance water reducer. Carbon nanotube 0.5kg, basalt fiber 8kg.

[0038] The slump of the obtained metal-ceramic concrete is 205mm, and the 28-day cubic compressive strength is 53.7MPa.

Embodiment 2

[0040] Each cubic meter of cermet concrete contains 500kg of cementitious materials (including 375kg of cement and 125kg of bauxite), 1050kg of cermet coarse aggregate, 685kg of quartz sand fine aggregate, 160kg of water, and 8.5kg of polycarboxylate high-performance water reducer , graphene 0.5kg, ceramic fiber 6kg.

[0041] The slump of the obtained metal-ceramic concrete is 185mm, and the 28-day cubic compressive strength is 67.1MPa.

Embodiment 3

[0043]Each cubic meter of cermet concrete contains 500kg of cementitious materials (including 420kg of cement and 80kg of bauxite), 1150kg of cermet coarse aggregate, 650kg of quartz sand fine aggregate, 175kg of water, and 5.5kg of polycarboxylate high-performance water reducer , nano zirconium carbide 1.5kg, carbon fiber 6kg.

[0044] The slump of the obtained metal-ceramic concrete is 200mm, and the 28-day cubic compressive strength is 56.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com