A kind of two-dimensional mesh ultrafine nanofiber composite liquid filter material and preparation method thereof

A nanofiber and two-dimensional network technology, which is applied in the field of composite liquid filtration materials and its preparation, can solve the problems of low material flux, low filtration efficiency, and reduction, and achieve wide application prospects, good pore connectivity, and high retention efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a two-dimensional network ultrafine nanofiber composite liquid filter material:

[0026] 1) Sodium chloride is dissolved in N,N-dimethylacetamide, stirred by a magnetic stirrer for 30min, ultrasonically ultrasonicated for 10min, the content of sodium chloride is 0.0001wt% of the total mass of the polymer solution, and then the granular Ethylene-vinyl alcohol copolymer, molecular weight 2×10 7 , added to N,N-dimethylacetamide dissolved with sodium chloride, stirred for 2 hours under 60°C water bath conditions, to obtain a uniform and stable polymer solution, the mass concentration of ethylene-vinyl alcohol copolymer in the solution was 0.001wt %, the viscosity of the resulting solution is 1mPa·s;

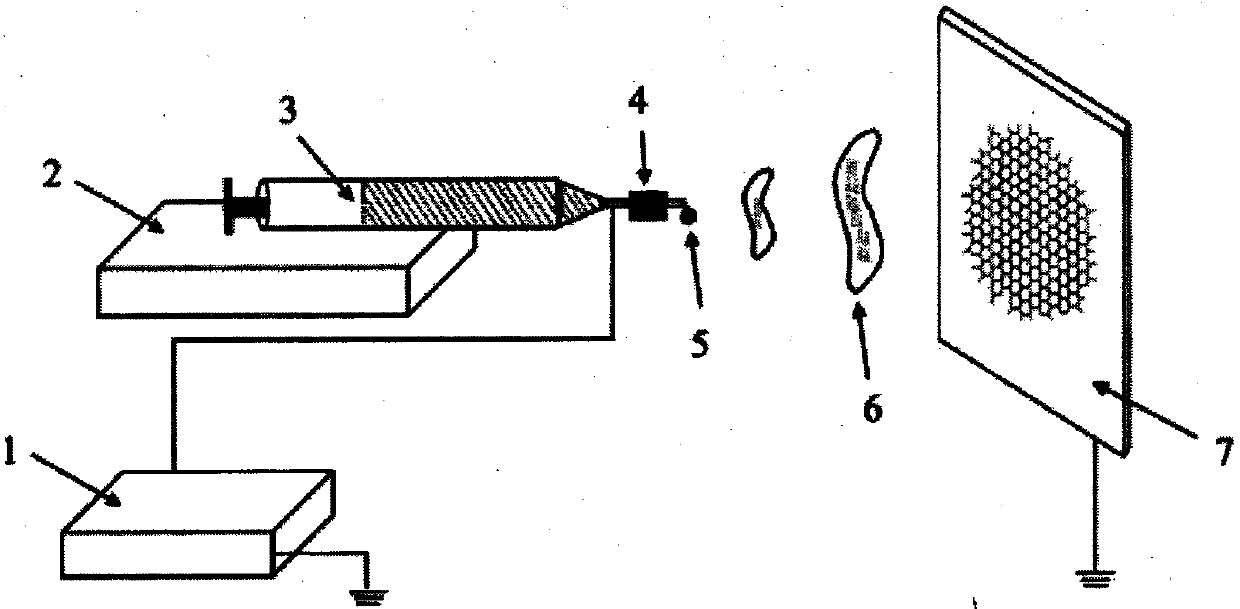

[0027] 2) use figure 1In the device shown, the polymer solution obtained above is transported to the spinneret of the injection device 3 through the liquid supply system 2, the injection device is connected to a DC high-voltage power supply 1, and the...

Embodiment 2

[0029] A preparation method of a two-dimensional network ultrafine nanofiber composite liquid filter material:

[0030] 1) Lithium chloride is dissolved in N,N-dimethylacetamide, stirred by a magnetic stirrer for 10min, ultrasonically ultrasonicated for 30min, the content of lithium chloride is 0.00075wt% of the total mass of the polymer solution, and then the granular Polyurethane polymer with a molecular weight of 1.3×10 7 , was added to the N,N-dimethylacetamide solvent dissolved with lithium chloride, stirred at room temperature for 5h to obtain a uniform and stable polymer solution, the mass concentration of polyurethane in the solution was 0.005wt%, and the viscosity of the resulting solution was 18mPa·s.

[0031] 2) use figure 1 In the device shown, the polymer solution obtained above is transported to the spinneret of the injection device 3 through the liquid supply system 2. The injection device is connected to a DC high-voltage power supply 1, and the receiving sub...

Embodiment 3

[0033] A preparation method of a two-dimensional network ultrafine nanofiber composite liquid filter material:

[0034] 1) Silver nitrate is dissolved in tetrahydrofuran, stirred by a magnetic stirrer for 35min, ultrasonic instrument ultrasonic 20min, the content of lithium chloride is 0.002wt% of the total mass of the polymer solution, and then the granular polystyrene high polymer with a molecular weight of 1.0×10 7 , added to the tetrahydrofuran solvent dissolved with silver nitrate, stirred at room temperature for 6h, to obtain a uniform and stable polymer solution, the mass concentration of polystyrene in the solution was 0.01wt%, and the viscosity of the obtained solution was 60mPa·s.

[0035] 2) use figure 1 In the shown device, the polymer solution obtained above is transported to the spinneret of the injection device 3 through the liquid supply system 2. The injection device is connected to a DC high-voltage power supply 1, and the receiving substrate 7 used is a por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com