Method for preparing neodymium, iron and boron by means of bonding by aid of high-uniformity adhesive

A production method and uniformity technology are applied in the production field of high-uniformity adhesive bonding RuFeB, which can solve the problems of difficulty in forming and demoulding, low stability of NdFeB, complicated preparation process, etc. To achieve the effect of easy molding and demoulding, reducing labor and equipment investment and energy costs, and proper particle grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of manufacture method of high-uniformity adhesive bonded RuFeB comprises the following steps:

[0022] (1): Magnetic powder particle size treatment: Use the NdFeB magnetic powder special grinding machine to grind the NdFeB magnetic powder until all the NdFeB magnetic powder passes through the 90-mesh sieve;

[0023] (2): Particle size treatment of auxiliary materials: extract γ-aminopropyltriethoxysilane, water and isopropanol according to mass percentage, and carry out proportioning;

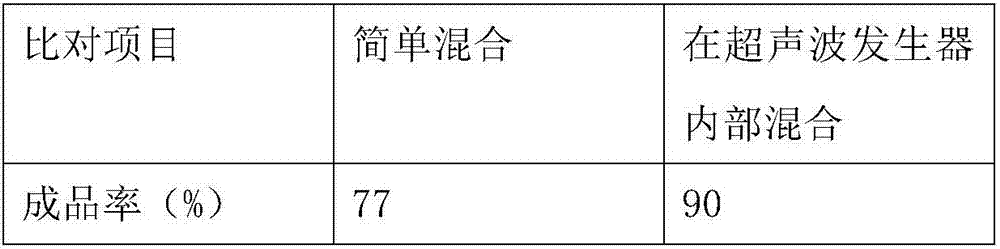

[0024] (3): Material drying: Mix the magnetic powder processed in step 1 and a part of the auxiliary materials processed in step 2 evenly inside the set ultrasonic generator, pour it into the drying tray for drying, and the other part directly Mixing, after pouring and drying, leave it in the drying tray to obtain the mixed material;

[0025] (4): Granulation: Pour polylaurolactam and the mixed material in step 3 into the special-purpose granulator of NdFeB respectively for granu...

Embodiment 2

[0032] A kind of manufacture method of high-uniformity adhesive bonded RuFeB comprises the following steps:

[0033] (1): Magnetic powder particle size treatment: Use the NdFeB magnetic powder special grinding machine to grind the NdFeB magnetic powder until all the NdFeB magnetic powder passes through the 90-mesh sieve;

[0034] (2): Particle size treatment of auxiliary materials: extract γ-aminopropyltriethoxysilane, water and isopropanol according to mass percentage, and carry out proportioning;

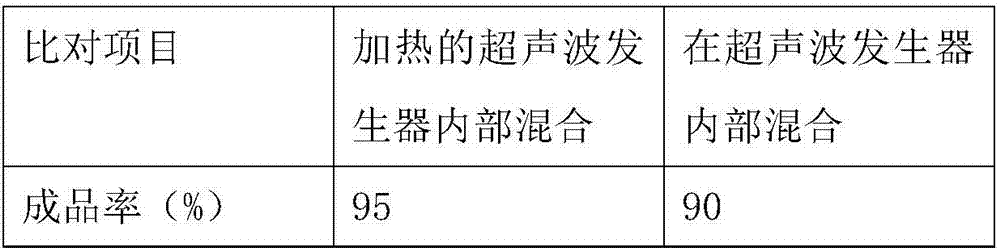

[0035] (3): Material drying: mix the magnetic powder processed in step 1 and a part of the auxiliary materials processed in step 2 evenly inside the set ultrasonic generator, pour it into the drying tray for drying, and the other part in the The set heating to 500°C inside the ultrasonic generator is mixed with, poured into the drying tray and left to stand in the drying tray to obtain the mixed material;

[0036] (4): Granulation: Pour polylaurolactam and the mixed material in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com