A kind of 80-95% solid content aqueous photocurable polyurethane acrylate and its preparation method

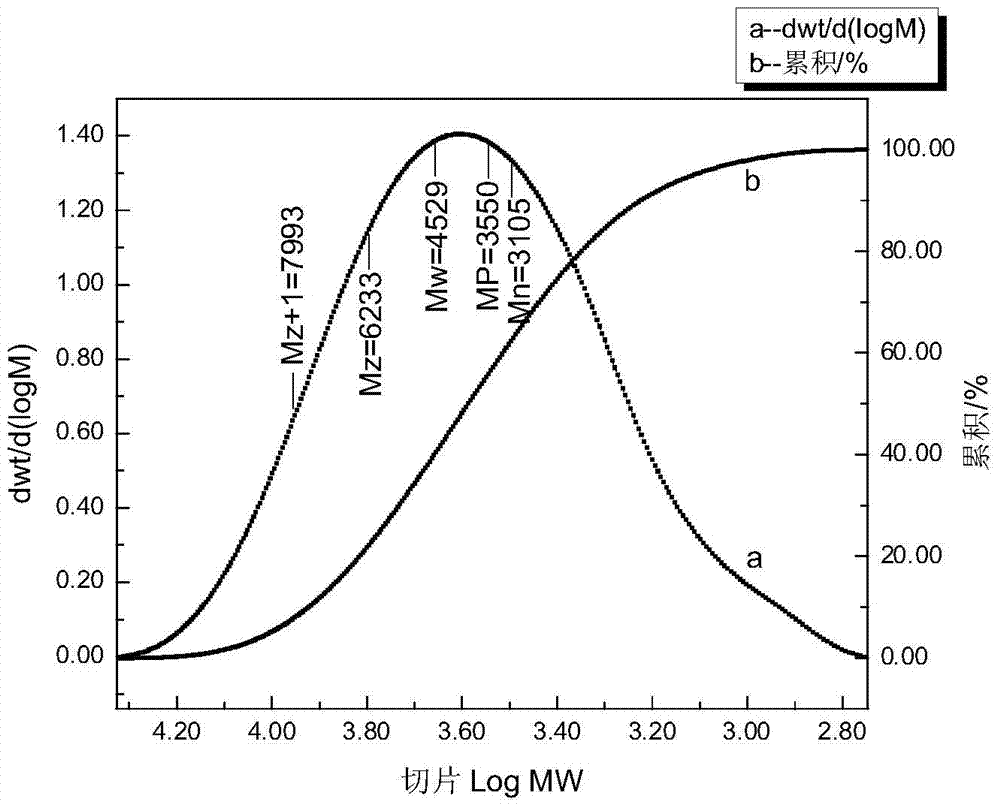

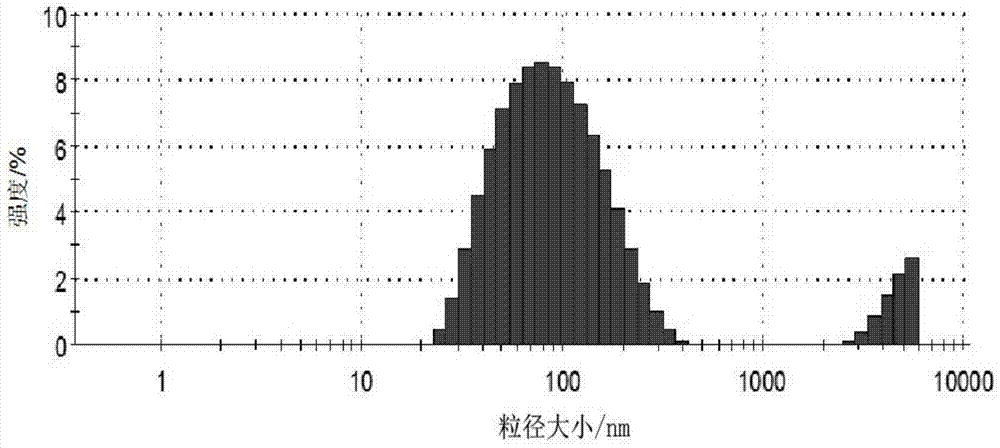

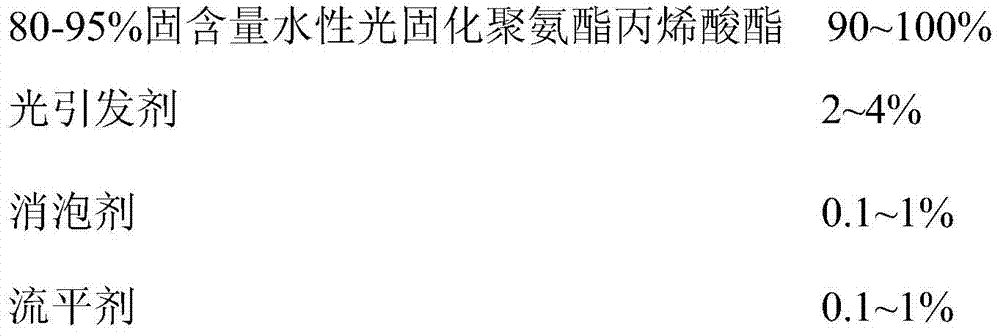

A technology of urethane acrylate and hydroxypropyl acrylate, which is applied in the field of 80-95% solid content water-based photocurable urethane acrylate and its preparation, can solve the problem that the solid content is only 50-60%, the strength is only 6.0MPa, and the solid content is only 50%. % and other issues, to achieve the effect of increasing equipment utilization, appropriate particle size distribution width, and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Synthesis of polyurethane prepolymer I: Add 32.5g isophorone diisocyanate (IPDI) and 24.4g polyoxypropylene glycol (Mw=1000) in a dry four-necked flask equipped with a stirrer and a thermometer, Add 0.06g of catalyst dibutyltin dilaurate dropwise, the reaction is carried out in a constant temperature water bath, the temperature is raised to 85°C, and the reaction is kept at this temperature for about 1.5h, and the content of -NCO is measured by the di-n-butylamine method. When the value is close to or lower than the theoretical value, the semi-blocked polyurethane prepolymer I is obtained;

[0045] (2) Synthesis of polyurethane prepolymer II: cool down to 70°C, weigh 9.8g of dimethylolpropionic acid (DMPA), dissolve it with 18.6g of acetone, place it in a dropping funnel, drop it into a four-necked flask, The dropping rate is 3s / drop, keep this temperature for 3h, during which a proper amount of acetone is added to adjust the viscosity, and the content of -NCO is me...

Embodiment 2

[0050] (1) Synthesis of polyurethane prepolymer I: add 38.1g of isophorone diisocyanate (IPDI) and 11.4g of polyethylene glycol (Mw=400) into a dry four-necked flask equipped with a stirrer and a thermometer, drop Add 0.05g catalyst dibutyltin dilaurate, react in a constant temperature water bath, raise the temperature to 85°C, keep this temperature for about 1.5h, measure the content of -NCO by the di-n-butylamine method, when the content of -NCO is the same as the theoretical value When it is close to or lower than the theoretical value, the semi-blocked polyurethane prepolymer I is obtained;

[0051] (2) Synthesis of polyurethane prepolymer II: cool down to 70°C, weigh 11.5g of dimethylolpropionic acid (DMPA), dissolve it with 23.0g of acetone, place it in a dropping funnel, drop it into a four-necked flask, The dropping rate is 3s / drop, keep this temperature for 3h, during which a proper amount of acetone is added to adjust the viscosity, and the content of -NCO is measure...

Embodiment 3

[0056] (1) Synthesis of polyurethane prepolymer I: add 34.6g isophorone diisocyanate (IPDI), 13.0g polyoxypropylene diol (Mw=1000) and 5.2g polyethylene glycol (Mw=400), add 0.05g catalyst dibutyltin dilaurate dropwise, the reaction is carried out in a constant temperature water bath, the temperature is raised to 85°C, and the temperature is maintained for about 1.5h, and the dibutylamine method is used. Measure the content of -NCO, when the content of -NCO is close to or lower than the theoretical value, the semi-blocked polyurethane prepolymer I is obtained;

[0057] (2) Synthesis of polyurethane prepolymer II: cool down to 70°C, weigh 9.6g of dimethylolpropionic acid (DMPA), dissolve it with 19.2g of acetone, put it in a dropping funnel, drop it into a four-necked flask, The dropping rate is 3s / drop, keep this temperature for 3h, during which a proper amount of acetone is added to adjust the viscosity, and the content of -NCO is measured by the di-n-butylamine method. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com