A temperature-resistant and salt-resistant inverse emulsion control and flooding system, its preparation method and application

A temperature-resistant, salt-resistant, inverse emulsion technology, applied in temperature-resistant and salt-resistant inverse emulsion control and flooding system, preparation of temperature-resistant and salt-resistant inverse emulsion control and flooding system, temperature-resistant and salt-resistant inverse emulsion control and flooding system in The application field in reservoir control and displacement can solve the problems of poor stability and achieve stable and controllable microsphere particle size distribution and improve the effect of control and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] The present invention has no particular limitation on the method of uniformly mixing the monomer mixture aqueous solution with the oily solvent and emulsifier, for example, the above three components can be stirred and mixed uniformly at the same time, or any two of them can be mixed After homogenization, add the third component and continue mixing. According to a preferred embodiment of the present invention, the uniform mixing method is to first mix the oily solvent and emulsifier to form a continuous oil phase, and then mix the continuous oil phase with the monomer mixture aqueous solution, so that A more uniform and stable emulsion can be obtained, which is conducive to the smooth control of the subsequent inverse emulsion polymerization reaction.

[0027]The type and amount of the oily solvent and emulsifier are not particularly limited in the present invention. For example, relative to 100 parts by weight of the monomer mixture, the amount of the oily solvent can...

Embodiment 1

[0048] This example is used to illustrate the preparation method of the temperature-resistant and salt-resistant inverse emulsion control and flooding system provided by the present invention.

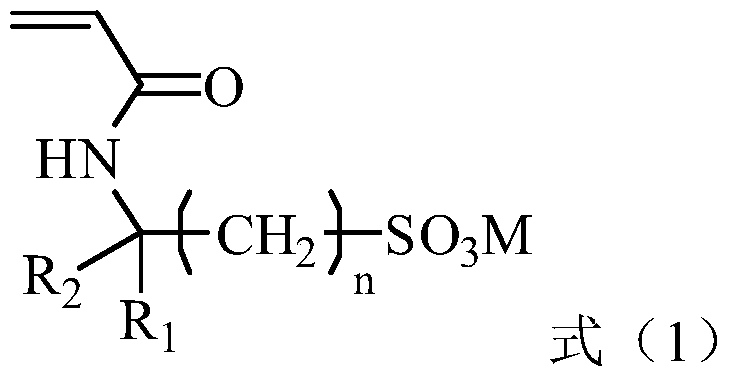

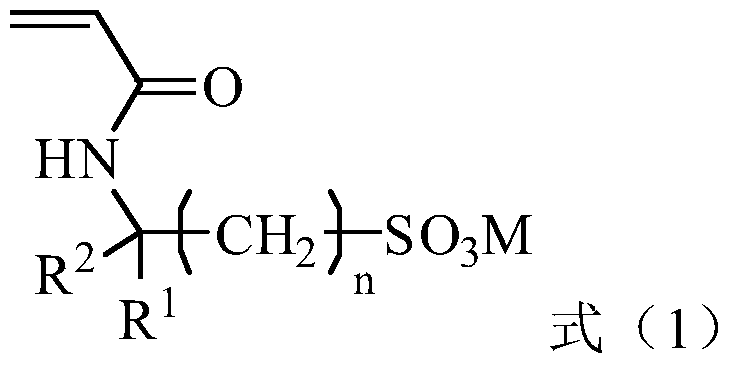

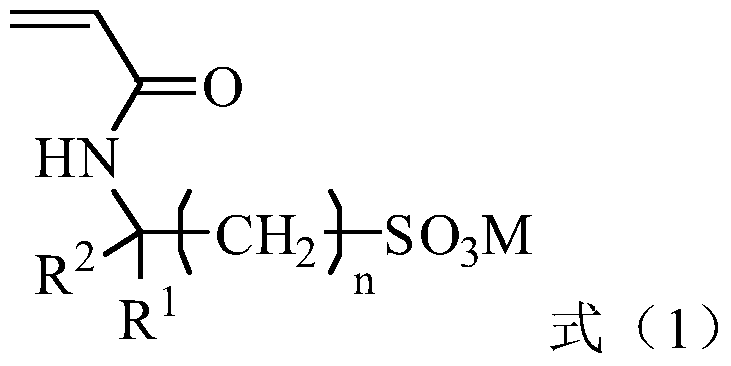

[0049] 60g of acrylamide, 15g of sodium acrylate, 54g of 2-acrylamido-2-methylpropanesulfonic acid and 0.25g of methylenebisacrylamide were dissolved in 90g of deionized water to obtain an aqueous solution, and adjusted with sodium carbonate The pH value of the aqueous solution is 7.2; 12g of Span 80 and 5g of Tween 80 are dissolved in 95g of white oil to obtain an oil phase, and then the aqueous solution and the oil phase are mixed, and emulsified by a high-speed disperser until the viscosity remains constant to obtain Stable white emulsion, injected into the reaction kettle. Under the condition of nitrogen protection, keep the temperature at 25°C and the stirring speed at 300rpm, add 0.5g EDTA-2Na, 0.8g urea aqueous solution (1% by weight) and 0.2g isopropanol, mix well, then add 1.0...

Embodiment 2

[0051] This example is used to illustrate the preparation method of the temperature-resistant and salt-resistant inverse emulsion control and flooding system provided by the present invention.

[0052]60g of acrylamide, 20g of itaconic acid, 60g of 2-acrylamido-2-propylpropanesulfonic acid and 0.25g of methylenebisacrylamide were dissolved in 90g of deionized water to obtain an aqueous solution, and hydrogenation was used to Sodium regulates the pH value of described aqueous solution to be 6.5; Dissolve 19.6g Siban 80 and 8.4g Tween 60 in 200g kerosene to obtain oily phase, then described aqueous solution and oily phase are mixed, utilize high-speed disperser to emulsify to viscosity Change to obtain a stable white emulsion, which is injected into the reaction kettle. Under the condition of nitrogen protection, keep the temperature at 25°C and the stirring speed at 300rpm, add 1g EDTA-2Na, 0.3g thiourea aqueous solution (1% by weight) and 0.03g tert-butanol, mix well, then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com