Heteroatom doped carbon aerogel and preparation method thereof

A carbon aerogel and heteroatom technology, which is applied in the field of heteroatom doped carbon aerogel and its preparation, can solve the problems of complex process, high cost, long time consumption and the like, and achieves simple and controllable process, low cost, The effect of favoring volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of nitrogen-doped carbon airgel of the present invention, comprising the following specific steps:

[0041] Weigh 1.18g Zn(NO 3 ) 2 ·6H 2 O and 0.67g 2-methylimidazole (Zn(NO 3 ) 2 ·6H 2 The molar ratio of O and 2-methylimidazole is 1:2) into a mortar, grind for 5 min, transfer to a quartz boat, heat at 5 °C / min to 150 °C for 2 h in an argon atmosphere, and then continue Heating at 5°C / min to 1000°C for 6h, followed by cooling at 5°C / min to obtain nitrogen-doped carbon aerogels.

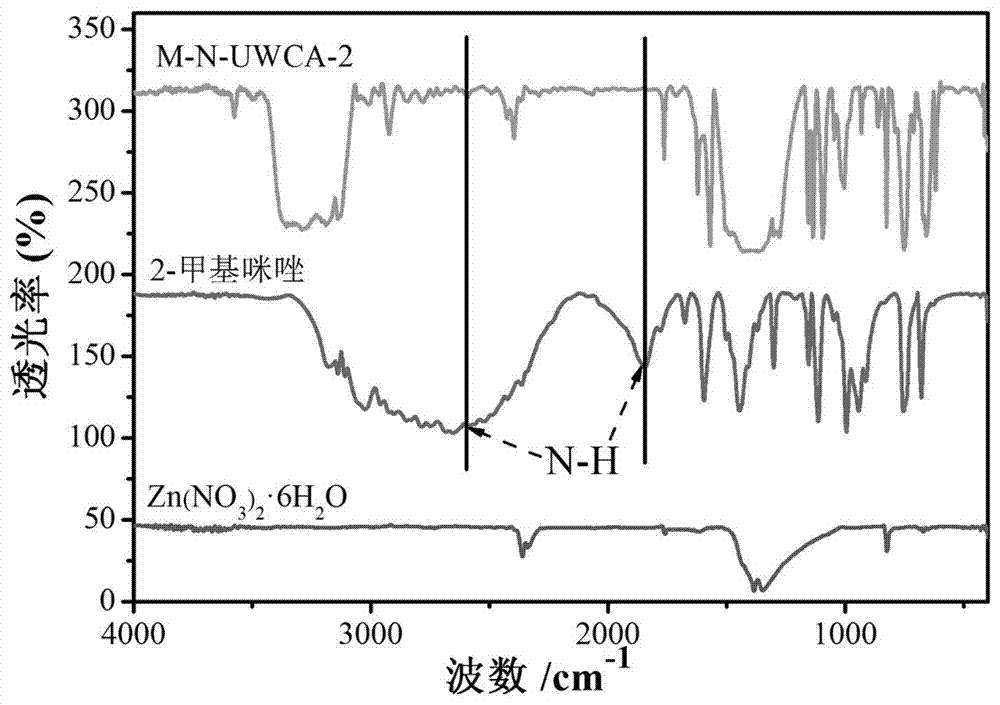

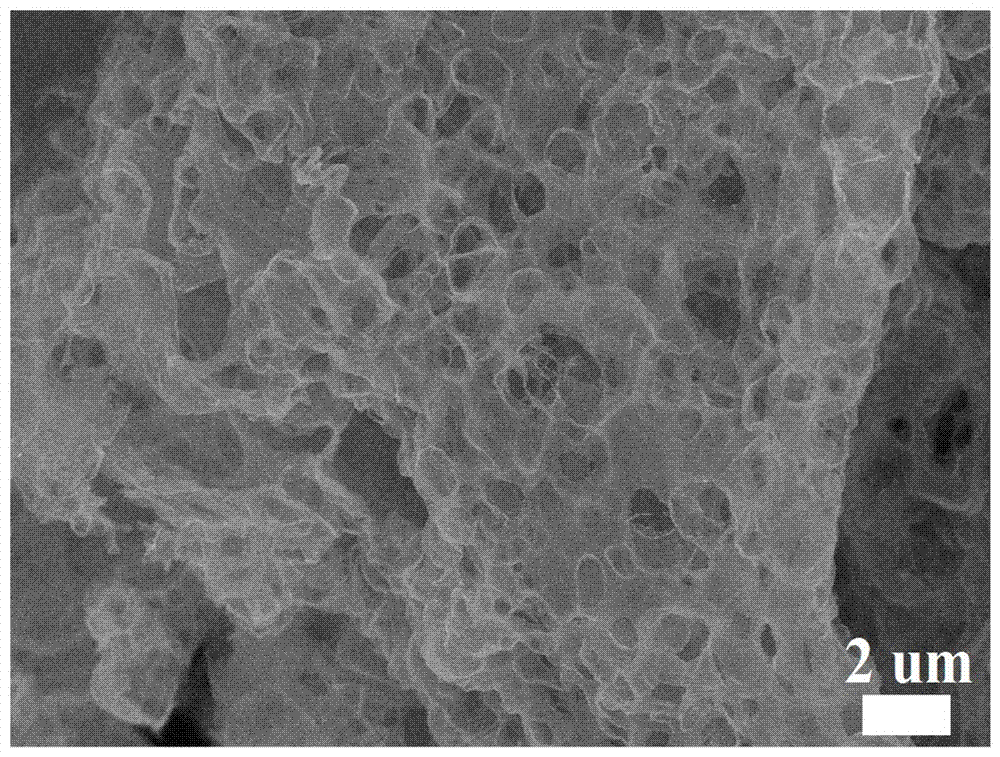

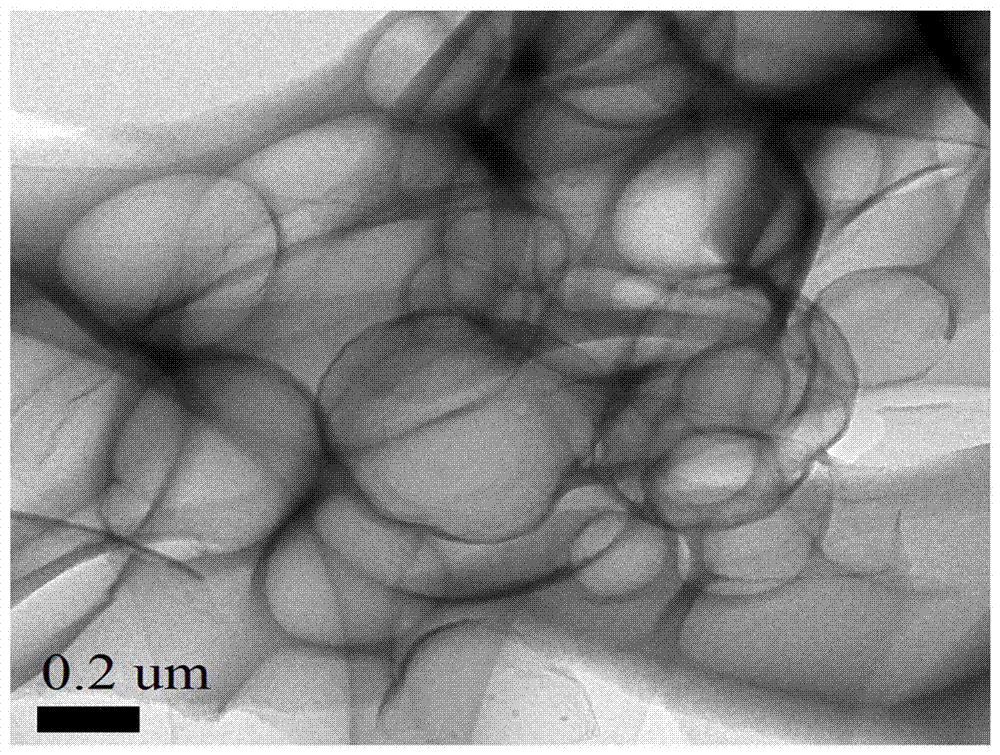

[0042] The infrared spectrogram of the coordination polymer of zinc nitrate and 2-methylimidazole in the present embodiment is as follows figure 1 As shown, it can be seen from the figure that the N-H bond disappears, which proves that Zn-N has been coordinated. The scanning electron microscope image of the nitrogen-doped carbon airgel prepared in this example is as follows figure 2 The transmission electron microscope image is shown in image 3 shown, combined w...

Embodiment 2

[0044] A preparation method of nitrogen and sulfur co-doped carbon aerogels of the present invention, comprising the following specific steps:

[0045] Weigh 0.97g Zn(NO 3 ) 2 ·6H 2 O, 0.41g 2-methylimidazole and 0.10g 2-mercaptoimidazole (the mol ratio of 2-methylimidazole and 2-mercaptoimidazole is 5:1, Zn(NO 3 ) 2 ·6H 2 The molar ratio of O to the mixture of 2-methylimidazole and 2-mercaptoimidazole is 1:2) Put it into a mortar, grind for 5min, transfer to a quartz boat, and heat at 5°C / min in an argon atmosphere to Insulate at 150°C for 2h, then continue to heat at 5°C / min to 1000°C for 6h, then cool down at 5°C / min to obtain an ultra-thin-walled carbon aerogel co-doped with nitrogen and sulfur.

[0046] The scanning electron microscope image of the nitrogen-doped carbon airgel prepared in this example is as follows Figure 8 As shown, it can be seen from the figure that the prepared airgel material has a three-dimensional porous structure and an ultra-thin wall stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com