Vacuum drying device and photolithographic process

A technology of vacuum drying device and photolithography process, which is used in drying solid materials, local stirring dryers, dryers for stationary materials, etc. It is difficult to volatilize and other problems, so as to reduce exposure, improve lithography accuracy, and facilitate solvent volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

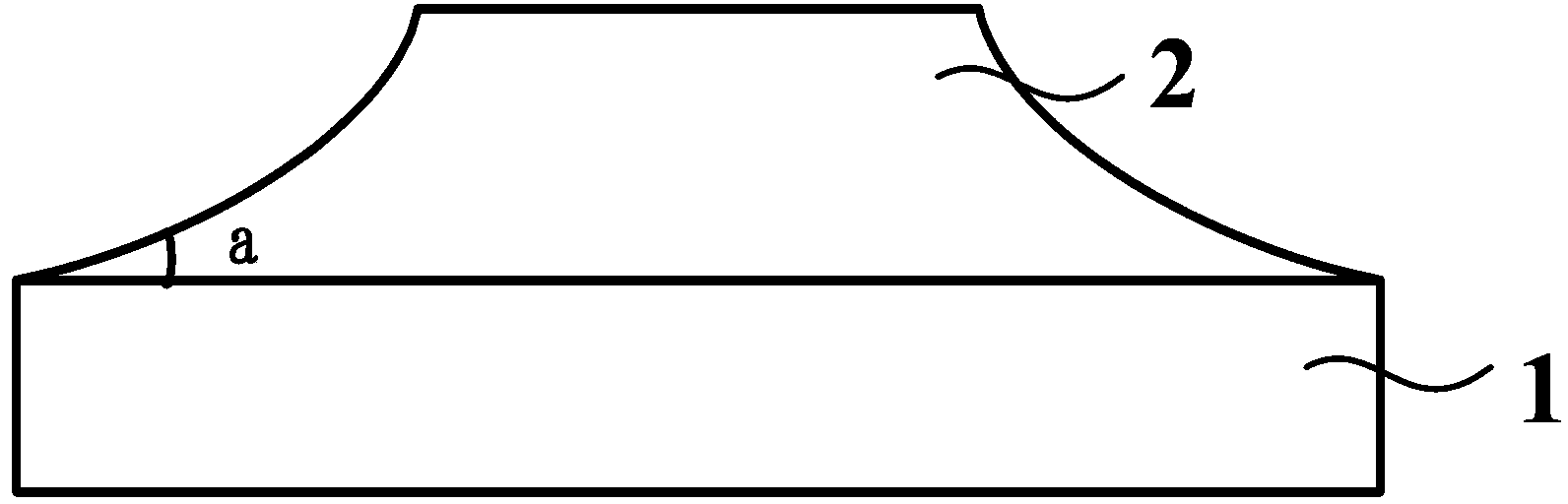

[0026] In order to reduce the residual amount of solvent in the photoresist after vacuum drying and improve the precision of photolithography, the invention provides a vacuum drying device and a photolithography process. The glue is heated to reduce the formation of a hardened film on the surface of the photoresist, thereby reducing the residual solvent in the photoresist and improving the photolithography precision.

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

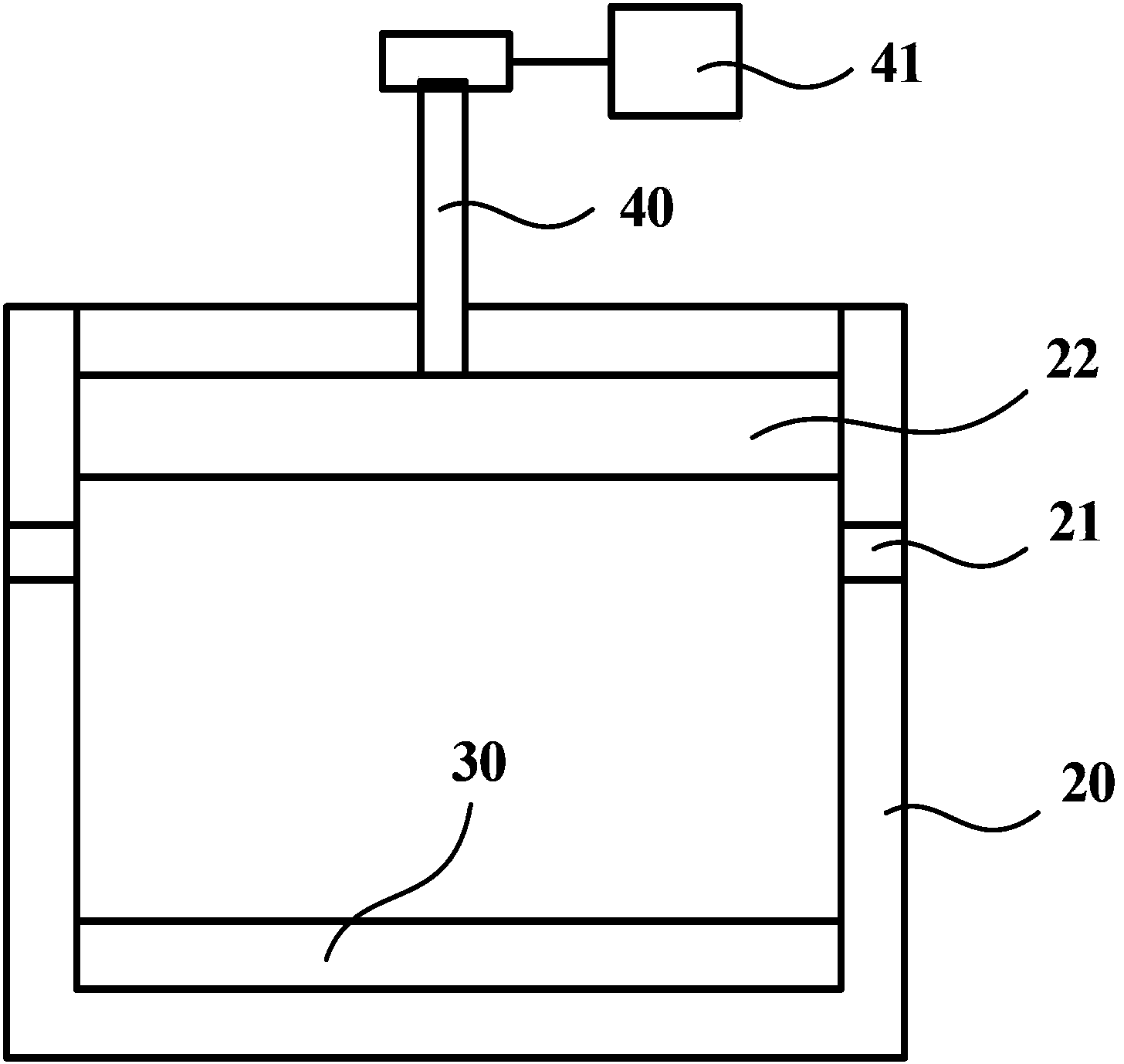

[0028] see figure 2 , is a schematic diagram of a vacuum drying device and its structure provided by an embodiment of the present invention. The vacuum drying device includes: a vacuum chamber 20 with an exhaust hole 21 and a door 22 , a vacuuming device (not shown in the figure) communicating with the exhaust hole 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com