Production method for low-yield-ratio high-strength medium-thickness steel plate

A production method and technology of low yield ratio, applied in the field of production of high-strength medium-thick steel plates with low yield ratio, can solve the problems of less application of low-carbon steel, achieve cost saving, short tempering time, and lower yield ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

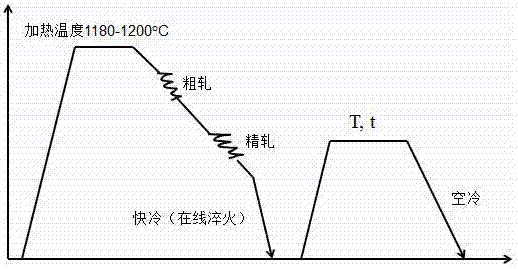

[0020] Embodiment one: the rolling of 25mm thick steel plate

[0021] The smelting composition of low alloy plate steel is C= 0.07, Si=0.3, Mn=1.56, Cr= 0.33, Nb= 0.04, Ti= 0.016, Mo= 0.15, B= 0.0005, P= 0.011, S= 0.002, The balance is Fe and unavoidable impurities, carbon equivalent CEQ = 0.43, cold crack sensitivity index Pcm = 0.19. After smelting, it is made into a continuous casting slab with a thickness of 260mm. Process steps include:

[0022] (1) Rolling process: After the continuous casting slab is heated by the heating furnace, the tapping temperature is 1180 o C, the thickness of the intermediate billet after 7 passes of rough rolling is 80mm, the reduction rate of the last three passes of rough rolling is above 20%, and the starting temperature of finish rolling is 935 o C, open and cold temperature is 800 o C, after online quenching, the red temperature is 440 o C with a cooling rate of 35 o C / s, rolled into a steel plate with a thickness of 25mm.

[0023] ...

Embodiment 2

[0027] Embodiment two: the rolling of 40mm thick steel plate

[0028]The smelting composition of low alloy plate steel is C 0.08, Si 0.28, Mn 1.61, Cr 0.31, Nb 0.045, Ti0.018, Mo 0.17, B 0.0008, P 0.013, S 0.002, the balance is Fe and unavoidable acrobatics Elements, carbon equivalent CEQ0.43, cold crack sensitivity index Pcm 0.19. After smelting, it is made into a continuous casting slab with a thickness of 260mm. Process steps include:

[0029] (1) Rolling process: After the continuous casting slab is heated by the heating furnace, the tapping temperature is 1190 o C, the thickness of the intermediate billet after 7 passes of rough rolling is 130mm, the reduction ratio of the last three passes of rough rolling is above 20%, and the starting temperature of finish rolling is 918 o C, open cold temperature is 785 o C, after online quenching, the red temperature is 320 o C with a cooling rate of 30 o C / s, rolled into a steel plate with a thickness of 40mm.

[0030] (2) He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com