Modified white graphene composite polypropylene tubular product, and preparation method thereof

A technology of compounding polypropylene and white graphene, which is applied in chemical instruments and methods, heat exchange materials, and other chemical processes, can solve the problems of easy agglomeration, poor compatibility of matrix materials, and affecting the performance of polypropylene, and achieve good results. Effects of gas barrier property, heat-resistant temperature improvement, and tensile breaking strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

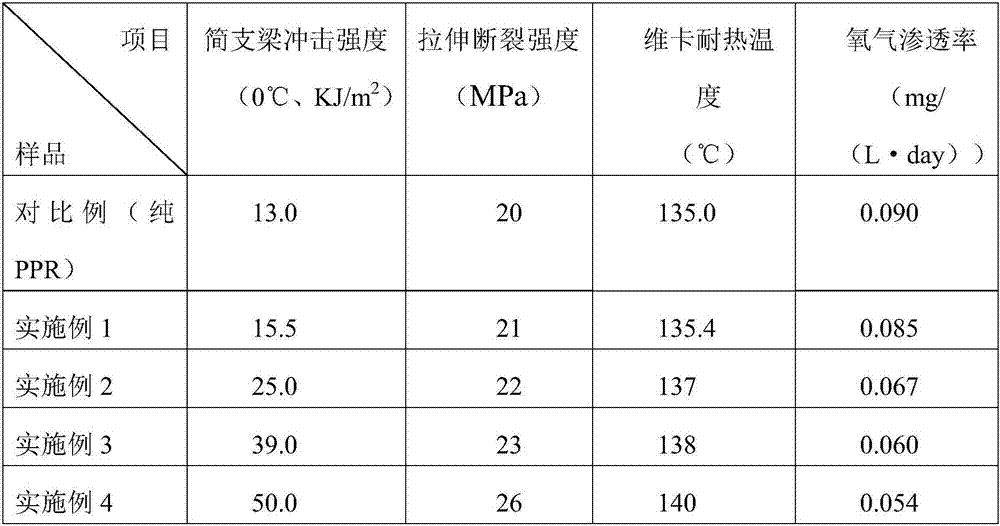

Examples

Embodiment 1

[0029] Step 1) Preparation of modified white graphene: select 5-10 layers of white graphene to soak in 0.1% polyvinyl alcohol aqueous solution for 24 hours, obtain modified white graphene after centrifugation and vacuum drying;

[0030] Step 2) Blending: Weigh 100 parts of pipe-grade random copolymerized polypropylene resin, 0.1 part of modified white graphene, 0.1 part of hindered phenol antioxidant 1010 and 0.1 part of stearic acid by weight parts respectively through a high-speed mixer Mix evenly for 10 minutes;

[0031] Step 3) Preparation of masterbatch: Melt and extrude the uniformly mixed raw materials in step 2) through a twin-screw extruder. Modified white graphene polypropylene masterbatch;

[0032] Step 4) Extrusion molding: Extrude the modified white graphene polypropylene masterbatch obtained in step 3) through a pipe extruder at a temperature of 150°C to obtain a finished product of modified white graphene composite polypropylene pipe .

Embodiment 2

[0034] Step 1) Preparation of modified white graphene: select 5-10 layers of white graphene to soak in 0.1% oleylamine aqueous solution for 24 hours, obtain modified white graphene after centrifugation and vacuum drying;

[0035] Step 2) Blending: Weigh 100 parts of pipe grade random copolymerized polypropylene resin, 1 part of modified white graphene, 0.3 part of hindered phenol antioxidant 1010 and 0.3 part of polyethylene wax by high-speed mixer Mix evenly for 10 minutes;

[0036] Step 3) Preparation of masterbatch: Melt and extrude the uniformly mixed raw materials in step 2) through a twin-screw extruder. Modified white graphene polypropylene masterbatch;

[0037] Step 4) Extrusion molding: Extrude the modified white graphene polypropylene masterbatch obtained in step 3) through a pipe extruder at a temperature of 155°C to obtain a finished product of modified white graphene composite polypropylene pipe .

Embodiment 3

[0039] Step 1) Preparation of modified white graphene: select 5-10 layers of white graphene to soak in 0.4% oleylamine aqueous solution for 24 hours, obtain modified white graphene after centrifugation and vacuum drying;

[0040] Step 2) Blending: Weigh 100 parts of pipe grade homopolypropylene resin, 3 parts of modified white graphene, 0.5 part of phosphite antioxidant 168 and 0.5 part of stearic acid by weight parts respectively through a high-speed mixer Mix evenly for 15 minutes;

[0041] Step 3) Preparation of masterbatch: Melt and extrude the uniformly mixed raw materials in step 2) through a twin-screw extruder. Modified white graphene polypropylene masterbatch;

[0042] Step 4) Extrusion molding: Extrude the modified white graphene polypropylene masterbatch obtained in step 3) through a pipe extruder at a temperature of 160°C to obtain a finished product of modified white graphene composite polypropylene pipe .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com