Addition reaction cured resin composition and photosemiconductor device

A curing resin, addition reaction technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of LED brightness reduction, and achieve the effect of good gas barrier properties, low oxygen permeability, and inhibition of brightness reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

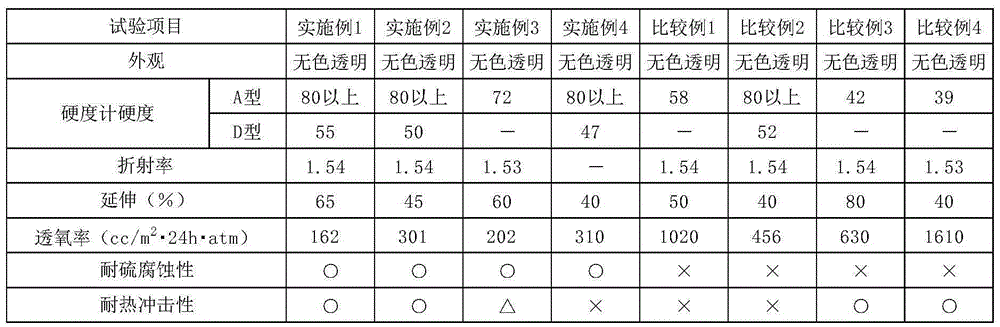

[0059] Next, the addition reaction curable resin composition of this invention is demonstrated in more detail through an Example and a comparative example.

[0060] 1. Manufacture of addition reaction curable resin composition

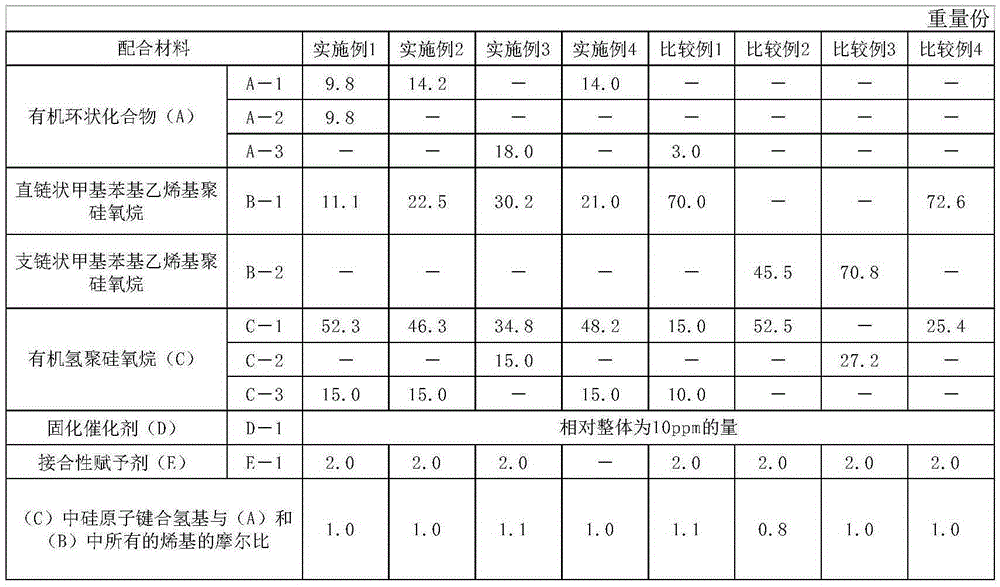

[0061] The compounding material shown in Table 1 was uniformly mixed in the compounding ratio shown in Table 1, and the addition reaction hardening type resin composition of Examples 1-4 and Comparative Examples 1-4 was manufactured. The units of numerical values indicating the compounding amounts in Table 1 are parts by weight. Each compounding material in Table 1 is as follows.

[0062] [Table 1]

[0063]

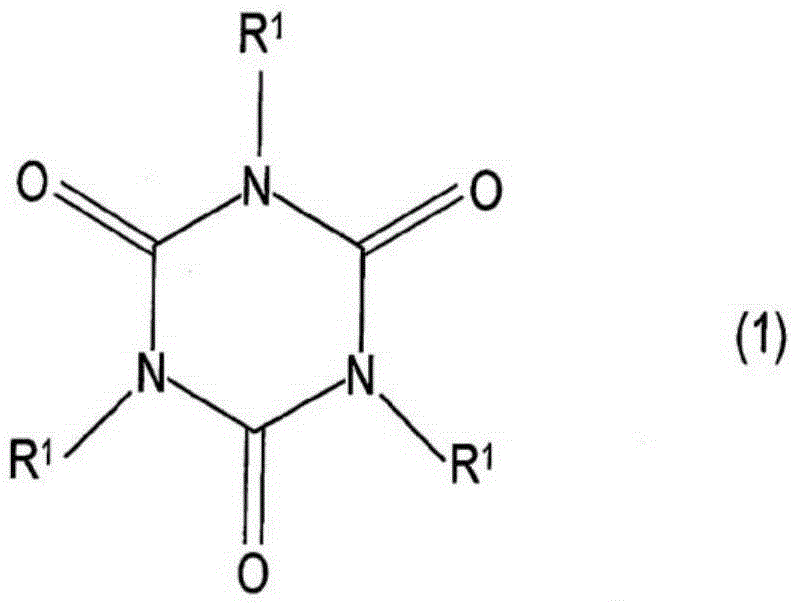

[0064] A-1: Triallyl isocyanurate

[0065] A-2: Diallyl monoglycidyl isocyanurate

[0066] A-3: Monomethyl diallyl isocyanurate

[0067] B-1: both ends by M Vi The unit is terminated, the middle unit is composed of D unit, D Vi Unit composition or intermediate unit includes D unit, D Vi Unitary linear methylphenylvinyl polysiloxane wi...

test approach 15

[0093] Each addition reaction curable resin composition was hardened at 150 degreeC for 4 hours, and the test piece of thickness 2mm was produced. The elongation of the test piece was measured in accordance with JIS K6249 (Test method 15. Tensile test for uncured and cured silicone rubber). The unit of extension is %.

[0094] Oxygen permeability

[0095] Each addition reaction curable resin composition was cured at 150° C. for 4 hours to form a sheet having a thickness of 1 mm. The oxygen permeability of the sheet was measured in accordance with JISK7126-1 (Plastic-Film and Sheet-Permeability Test Method-Part 1: Pressure Difference Method).

[0096] Sulfur corrosion resistance

[0097] Each addition reaction curable resin composition was filled in the LED package (outside dimension 50x50 mm) whose bottom was plated with silver, and it cured at 150 degreeC for 4 hours, and it was set as the test body. Three of these test bodies were sealed in a 100 cc glass bottle prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com