Preparation method of o-fluorotobuene

A technology of o-fluorotoluene and o-toluidine, applied in the field of preparation of fluorine-containing compounds, can solve the problems of long production cycle and low content of fluorination, and achieve the effects of high degree of automation, reduction of side reactions and short reaction cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

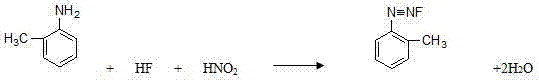

[0029] The preparation method of o-fluorotoluene of the present invention comprises the following steps:

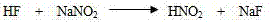

[0030] 1. Reaction steps for generating nitrous acid: Add 80kg of anhydrous hydrogen fluoride to the reactor, turn on the tail gas absorption system, keep the reactor at a slight negative pressure, add 135kg of sodium nitrite for reaction, and the addition rate is about 40kg / h, continue after adding React for 1 hour; the reaction between anhydrous hydrogen fluoride and sodium nitrite is exothermic violently, and cooling liquid needs to be passed through during the reaction, and the temperature in this step should be controlled at -3~0°C.

[0031] 2. Diazotization reaction step: Add 200kg of o-toluidine dropwise into the reaction kettle, the dropping rate is about 70kg / h, stir at 63r / min, raise the temperature to -1~1°C, after the dropwise addition, keep the temperature for 1 hour, Obtain diazo solution.

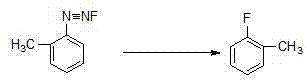

[0032] 3. Thermal decomposition reaction step: the diazo solution ...

Embodiment 2

[0036] Prepare according to the preparation method of o-fluorotoluene in embodiment 1, only change the following parameters of the following steps of embodiment 1:

[0037] 1. Reaction steps for generating nitrous acid: Add 80kg of anhydrous hydrogen fluoride to the reactor, turn on the tail gas absorption system, keep the reactor at a slight negative pressure, add 135kg of sodium nitrite for reaction, and the addition rate is about 45kg / h, continue after adding React for 1 hour; the reaction between anhydrous hydrogen fluoride and sodium nitrite is exothermic violently, and cooling liquid needs to be passed through during the reaction, and the temperature in this step should be controlled at -1~1°C.

[0038] 2. Diazotization reaction step: add 206kg of o-toluidine dropwise into the reaction kettle, the dropping rate is about 90kg / h, stir at 63r / min, raise the temperature to 0~3°C, after the dropwise addition, keep warm for 1 hour to get Diazo solution.

[0039] 3. Thermal de...

Embodiment 3

[0043] 1. Reaction steps for generating nitrous acid: Add 80kg of anhydrous hydrogen fluoride to the reactor, turn on the tail gas absorption system, keep the reactor at a slight negative pressure, add 140kg of sodium nitrite for reaction, and the addition rate is about 50kg / h, continue after adding React for 1 hour; the reaction between anhydrous hydrogen fluoride and sodium nitrite is exothermic violently, during the reaction process, cooling liquid needs to be passed through, and the temperature in this step should be controlled at 0-3°C.

[0044]2. Diazotization reaction step: Add 210kg of o-toluidine dropwise into the reaction kettle, the dropping rate is about 100kg / h, stir at 63r / min, and raise the temperature to 3~5°C. Diazo liquid.

[0045] 3. Thermal decomposition reaction step: the diazo solution generated by the reaction is injected into the tubular reactor by compressed nitrogen gas for thermal decomposition reaction. After adding the diazo solution, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com