Heat-insulating concrete containing aerogel grains and preparation method thereof

A technology of aerogel particles and gel particles, applied in the field of building materials, can solve the problems of low aerogel density, poor self-strength, poor compressive strength, etc., and achieves broad market application space, good thermal insulation effect, crack resistance, etc. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

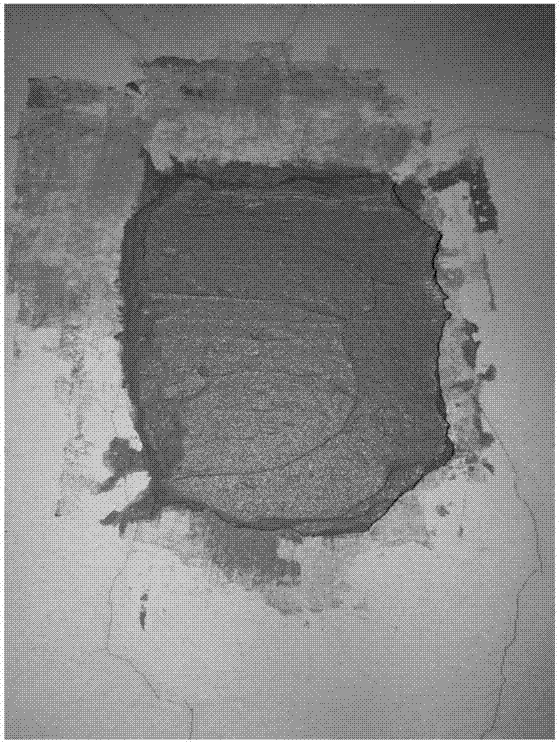

Image

Examples

Embodiment 1

[0030] Weigh each raw material according to the following ratio:

[0031] 32.5# Portland cement (Conch brand) 100 parts, fly ash (Shanghai Shidongkou Power Plant) 30 parts, reinforced airgel particles (self-made) 25 parts, hydroxypropyl methylcellulose (Xi'an Ruitai cellulose Co., Ltd.) 0.5 part, polyethylene glycol (Dow Chemical) 0.5 part, redispersible latex powder (Germany Wacker) 1 part, anti-crack fiber (Jining Huakai Resin Co., Ltd.) 1 part.

[0032] Wherein, the preparation method of reinforced airgel particles is: 1 weight part of airgel particles (Shanghai Yapeng New Material Technology Co., Ltd.) is crushed to 120 mesh with a crusher, and 8 parts by weight of polyvinyl alcohol (Anhui Wanwei Co., Ltd.) is used High-tech Materials Co., Ltd.) aqueous solution is used as a binder, and the fluidized bed granulation method is used to make particles with an average particle diameter of 2 mm.

[0033] Thereafter, the raw materials weighed above were mixed uniformly.

[003...

Embodiment 2

[0039] Weigh each raw material according to the following ratio:

[0040] 100 parts by weight of 42.5# Portland cement (Conch brand), 10 parts by weight of reinforced airgel particles (self-made), 1 part by weight of hydroxymethyl cellulose (Shijiazhuang Hengli Cellulose Co., Ltd.), polyvinyl alcohol (Anhui Wanwei High-tech Materials Co., Ltd.) 1 part by weight, redispersible latex powder (Wacker, Germany) 1 part by weight, wood anti-cracking fiber (Shanghai Yingjia Industrial Development Co., Ltd.) 1 part by weight

[0041] Wherein, the preparation method of reinforced airgel particles is: 1 weight part of airgel particles (Shanghai Yapeng New Material Technology Co., Ltd.) is mixed with 5 weight parts of styrene-acrylic emulsion (Shanghai Shenze Chemical Technology Co., Ltd.) The agitator stirred for 5 minutes, and the agglomerated airgel was obtained after drying, and the agglomerated airgel was broken into 35-mesh particles with a crusher.

[0042] Thereafter, the raw mat...

Embodiment 3

[0047] Weigh each raw material according to the following ratio:

[0048] 100 parts by weight of 42.5# Portland cement (Conch brand), 20 parts by weight of reinforced airgel particles (self-made), 0.5 parts by weight of hydroxypropyl methylcellulose (Xi'an Ruitai Cellulose Co., Ltd.), polyacrylamide ( Shanghai Jinjinle Chemical Factory) 1 part by weight, redispersible latex powder (Wacker, Germany) 1 part by weight, polypropylene anti-crack fiber (Jining Huakai Resin Co., Ltd.) 0.5 part by weight, wood anti-crack fiber (Shanghai Yingjia Industrial Development Co., Ltd.) Ltd.) 0.5 parts by weight.

[0049] Among them, the preparation method of reinforced airgel particles is: adding bacterial cellulose skeleton in the process of making airgel, making the gel grow in the cellulose network, and making the formed airgel be bound in the cellulose network , forming reinforced airgel particles.

[0050] Wherein, the preparation method of the bacterial cellulose skeleton is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com