Honeycomb type SCR denitration catalyst calcining furnace and method for drying SCR denitration catalyst

A denitrification catalyst and honeycomb technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of inconvenient automatic continuous production, low production stability, and high labor intensity , to achieve the effect of improving the utilization rate of raw materials, expanding the scale of production specifications, and enhancing the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

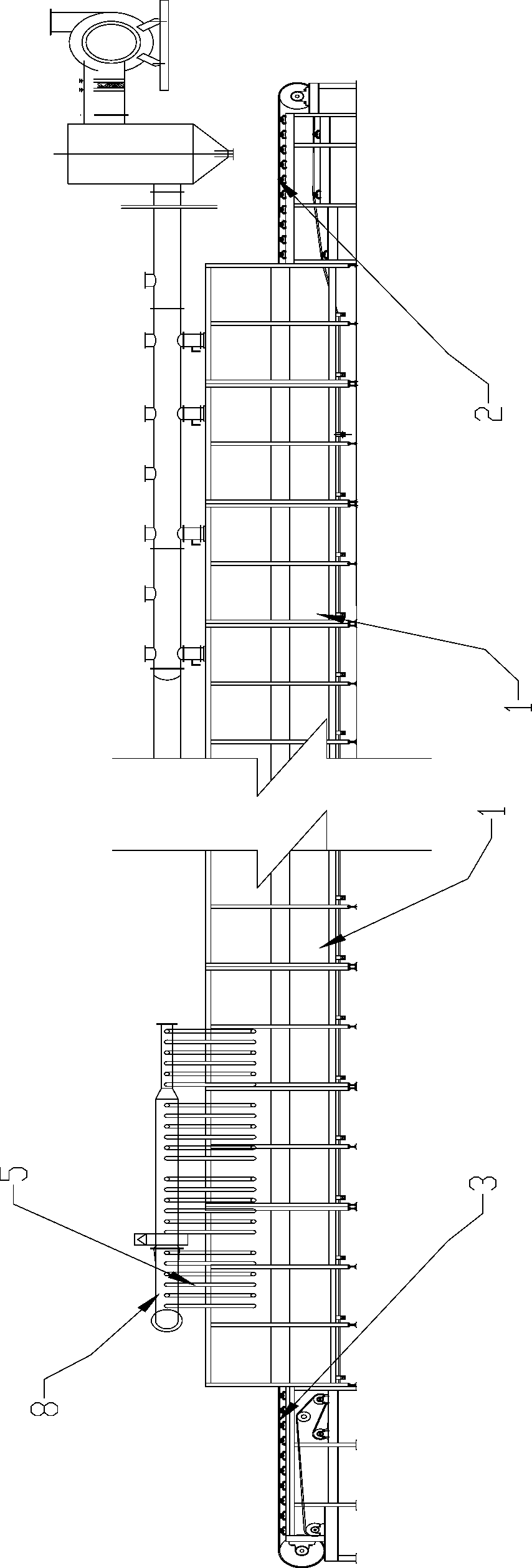

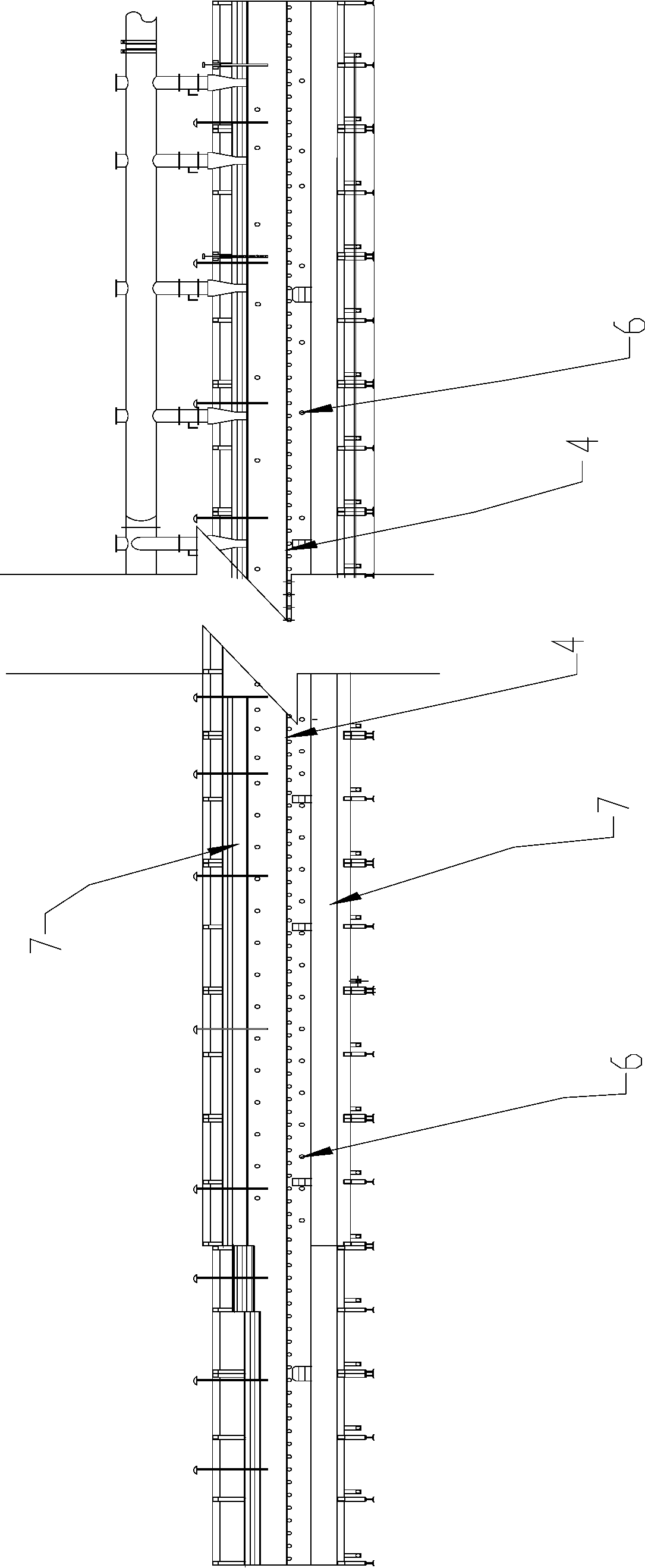

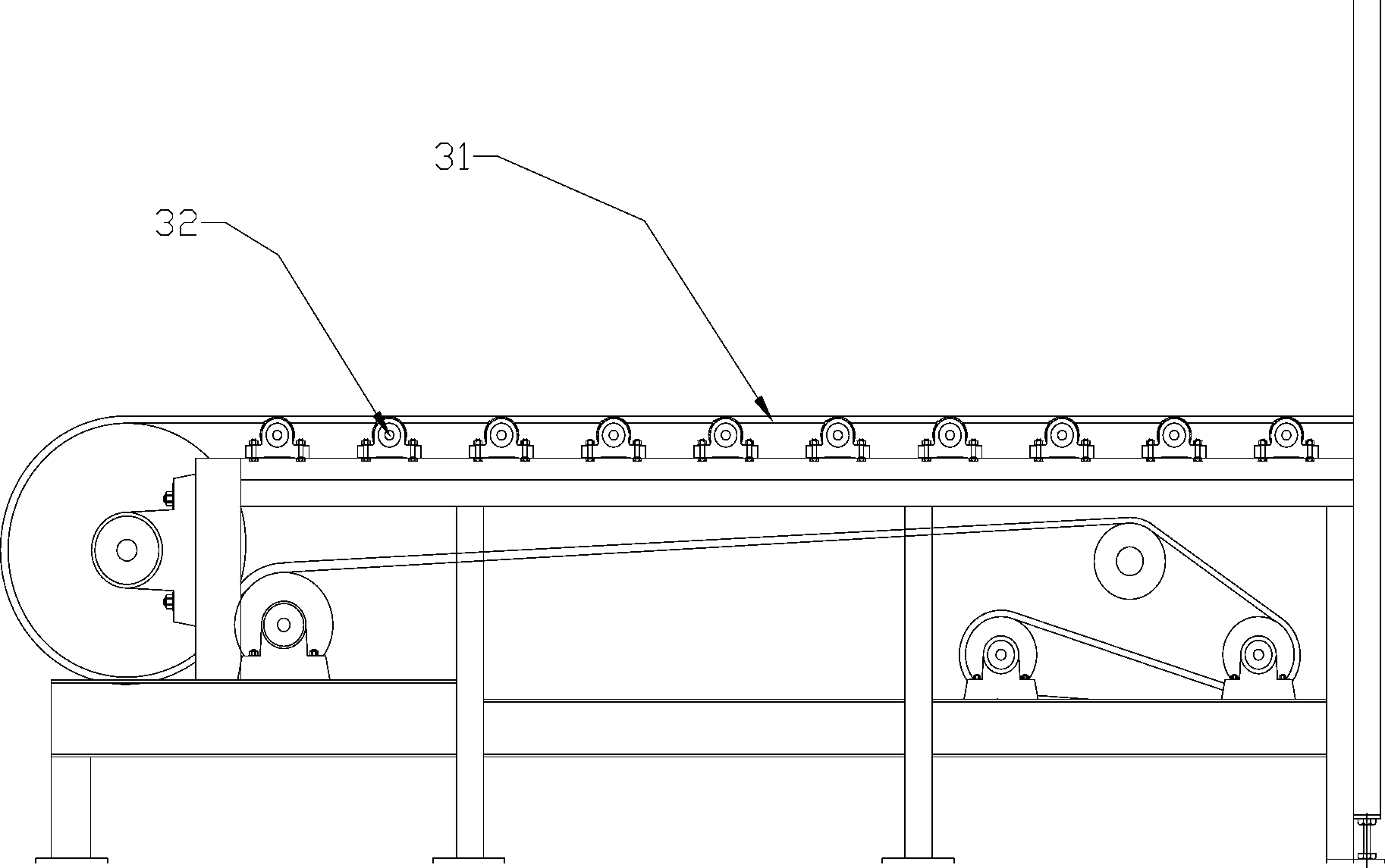

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see accompanying drawing, a kind of honeycomb type SCR denitration catalyst calciner, comprises furnace body 1, conveying device, heating device, and described conveying device comprises feeding platform 2, Conveying platform 4, discharging platform 3, described conveying device also comprises the mesh belt 31 that rotates on described feeding platform 2, conveying platform 4, discharging platform 3, and described heating device is arranged in furnace body 1 The far-infrared quartz heating tube 6, the end of the furnace body 1 is provided with a cooling area, and the cooling area is provided with a heat exchange tube 5, and the heat exchange tube 5 is connected to the heat extraction fan 8, and the mesh belt 31 on both sides An automatic deviation correction device is provided, and the automatic deviation correction device includes guide wheel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com