Thin film type temperature sensor

A temperature sensor and thin-film technology, which is applied in thermometers, instruments, scientific instruments, etc., can solve the problems that thin-film temperature sensors are not suitable for humid environments, the metal bracket cannot be long, and it is difficult to meet the needs of customers, so as to increase the length, Good insulation effect and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

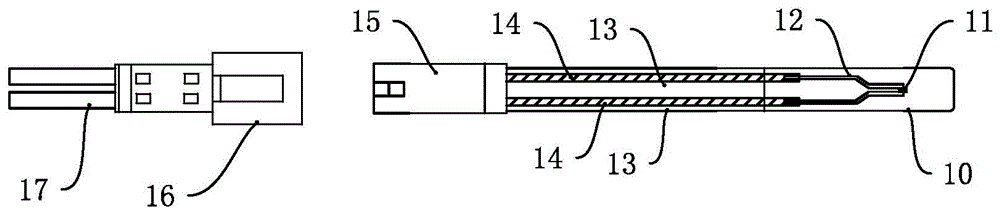

[0024] The first embodiment, such as figure 1 As shown, a thin-film temperature sensor includes a metal support 12, an NTC thermistor 11 located at one end of the metal support 12, a rolled wire 14 located at the other end of the metal support 12, and a terminal hole located at the other end of the rolled wire 14. The seat 15 is used to cover the metal bracket 12 and the film 10 of the NTC thermistor 11 and the FFC or FPC flexible cable 13 used to wrap the rolled wire 14; one end of the FFC or FPC flexible cable 13 is connected to the film 10, and the other end is connected to the The terminal socket 15 is connected. Wherein, the NTC thermistor 11 is fixedly connected to one end of the metal bracket 12 by welding. The rolled wire 14 is fixedly connected to the other end of the metal bracket 12 by welding. The film 10 is made of polyimide, PET plastic, aramid, aramid, polyether ether ketone or silicone rubber. The thickness of the film 10 is 0-2 mm.

[0025] The NTC thermis...

no. 2 example

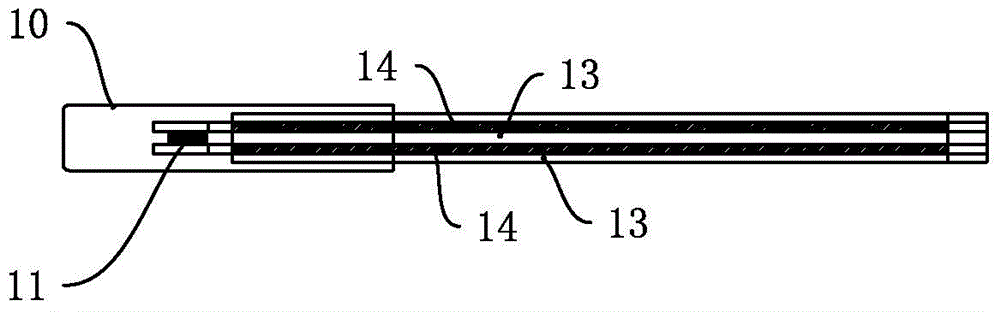

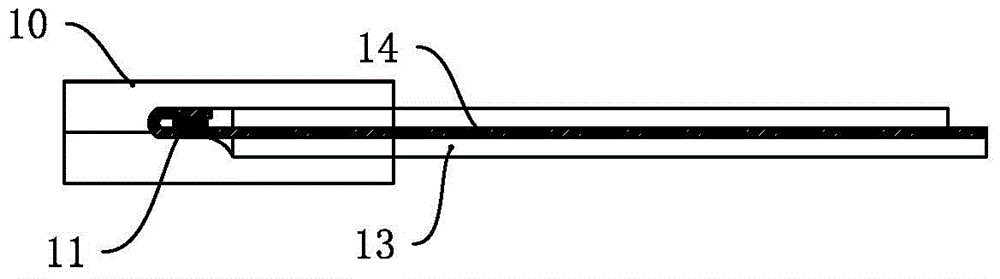

[0027] Second embodiment, such as figure 2 and image 3 As shown, a film-type temperature sensor includes a bare-chip NTC thermistor 11, a rolled wire 14 connected to the bare-chip NTC thermistor 11, a film 10, and an FFC or FPC flexible cable 13; the film 10 wraps the bare chip Type NTC thermistor 11 and one end of the rolled wire 14, and the FFC or FPC flexible flat cable 13 wraps the rolled wire 14.

[0028] The thin-film NTC temperature sensor is used in low temperature, and one end of the two rows of rolled wires 14 exposes the FFC flexible cable 3; use a jig to bend the exposed rolled wires 14 into a parallel shape, and then insert an NTC thermistor 11 of appropriate size into the rolled wires 14 bare parts. Although the single layer of the rolled wire 14 is very thin, after the rolled wire 14 is bent into a parallel state by a jig, two parallel rolled wires 14 are used to clamp the electrodes of the bare-chip NTC thermistor 11 so that it is not easy to fall off, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com