Magnesium-aluminum sol and its preparation method and application, catalytic cracking catalyst and its preparation method

A technology of magnesium-aluminum sol and aluminum sol, which is applied in the field of catalytic cracking catalyst and its preparation, can solve the problems of poor catalyst strength, high drying temperature, and high evaporation heat, and achieve reduced addition, low corrosion rate, and free chlorine ion little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

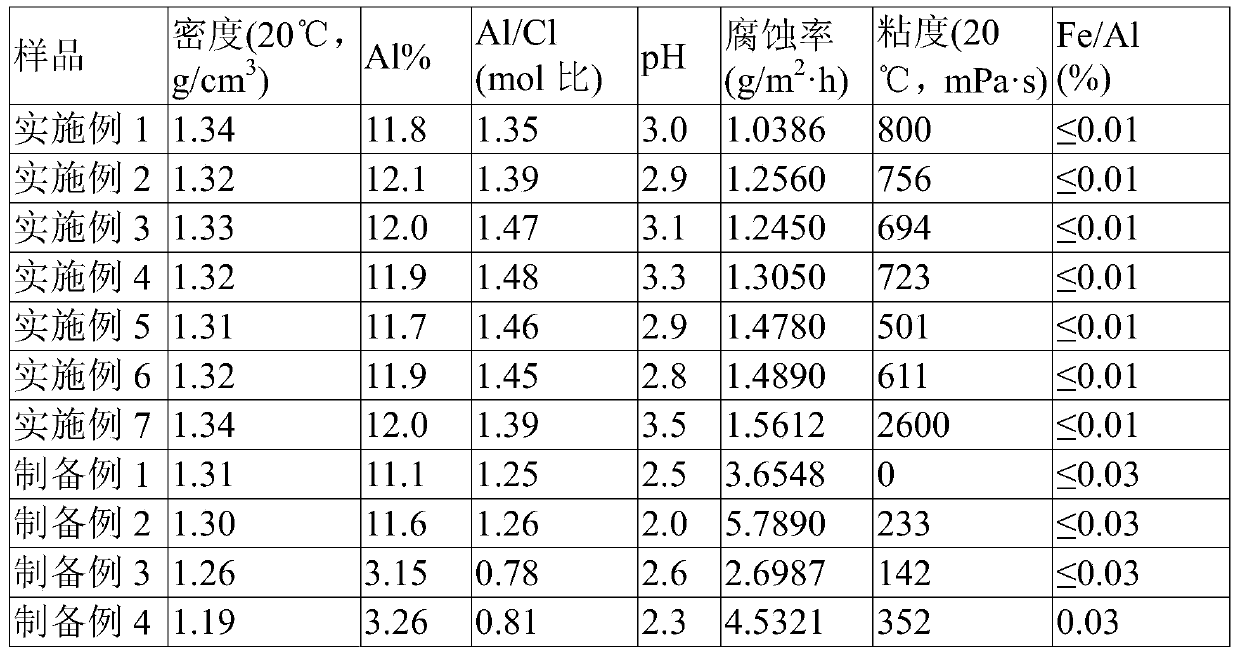

[0056] The method for preparing aluminum sol of the present invention can reduce the amount of hydrochloric acid used, the added amount of chloride ions, reduce the damage of the properties of the aluminum sol by free acid, improve the activity of the aluminum sol, and at the same time can avoid the pH value of the aluminum sol caused by excessive hydrochloric acid. If it is too low, it will destroy the molecular sieve and affect the catalyst activity.

[0057] In the method for preparing an aluminum sol of the present invention, the first contact and the second contact are accompanied by stirring, and when the stirring is stopped, the process of the first contact and the second contact ends. The time of the first contact and the second contact described below is the time under which stirring is continued.

[0058] According to a preferred embodiment of the present invention for preparing the aluminum sol, the temperature of the first contact is 50-80°C.

[0059] According to...

Embodiment approach

[0076] According to a preferred embodiment of the preparation method of magnesium-aluminum sol of the present invention, it further comprises: secondly mixing the product obtained by the first mixing with phosphorus compound and / or rare earth compound; the second mixing temperature is 30-60 ℃ °C, and the second mixing time is 0.5 to 2 hours.

[0077] In the preparation method of the magnesium-alumina sol of the present invention, the first mixing and the second mixing are accompanied by stirring, and when the stirring is stopped, the first mixing and the second mixing are completed. The time of the first mixing and the second mixing described below is the time under which the stirring is continued.

[0078] In the preparation method of the magnesium-aluminum sol of the present invention, preferably, before the second mixing is performed, the product obtained by the first mixing is allowed to stand at room temperature for 0.5-1.5 h. The standing means that after the stirring a...

Embodiment 1

[0127] This example illustrates the preparation method of the aluminum sol of the present invention.

[0128] (1) carry out the first contact with 1mol metal aluminum (China Aluminum Corporation) and 1mol (HCl) hydrochloric acid, control the first contact process temperature to be 50 ° C, the first contact time is 3h, and the initial concentration of hydrochloric acid used is 32% by weight ;

[0129] (2) The mixture after the first contact was allowed to stand at room temperature of 20°C for 6 hours, and then mixed with γ-Al 2 O 3 (Shandong Aluminum Plant) and η-Al 2 O 3 (Shandong Aluminum Factory) to carry out the second contact, the second contact temperature is 30 ℃, the second contact time is 4h, the γ-Al in terms of aluminum 2 O 3 , η-Al in terms of aluminum 2 O 3 The molar ratio to the metal aluminum of step (1) is 0.05:0.05:1. The physicochemical properties of the aluminum sol are shown in Table 1.

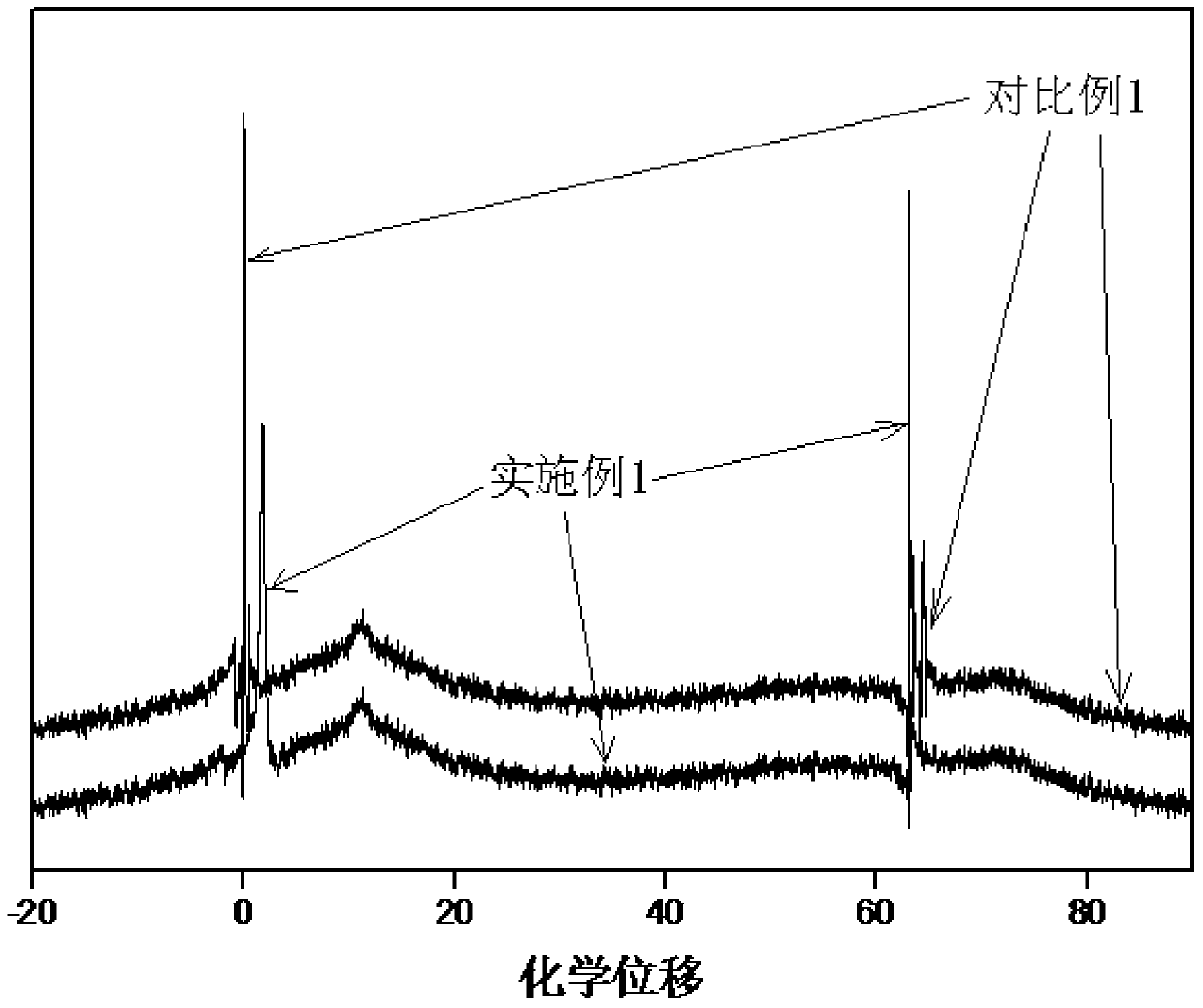

[0130] aluminum sol 27 Al NMR measurement, see the spectrum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com