Manufacturing method for junction, manufacturing method for substrate for power module with heat sink, and manufacturing method for heat sink

A manufacturing method and technology for power modules, which are applied in semiconductor/solid-state device manufacturing, manufacturing tools, electrical solid-state devices, etc., can solve the problems of reduced heat dissipation characteristics and increased thermal resistance, and achieve the effect of improving heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

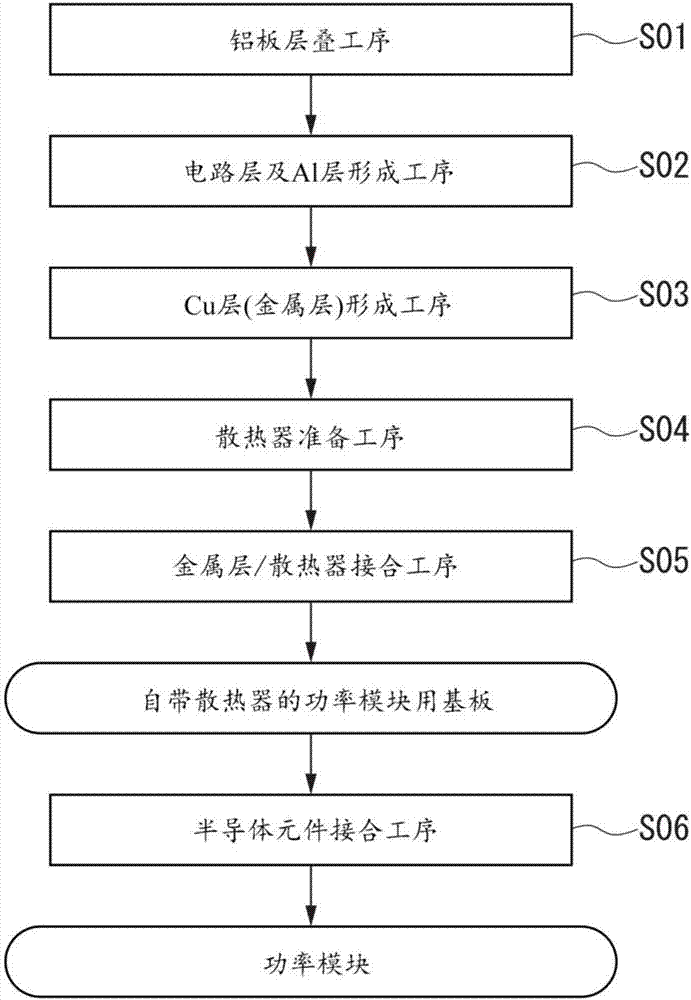

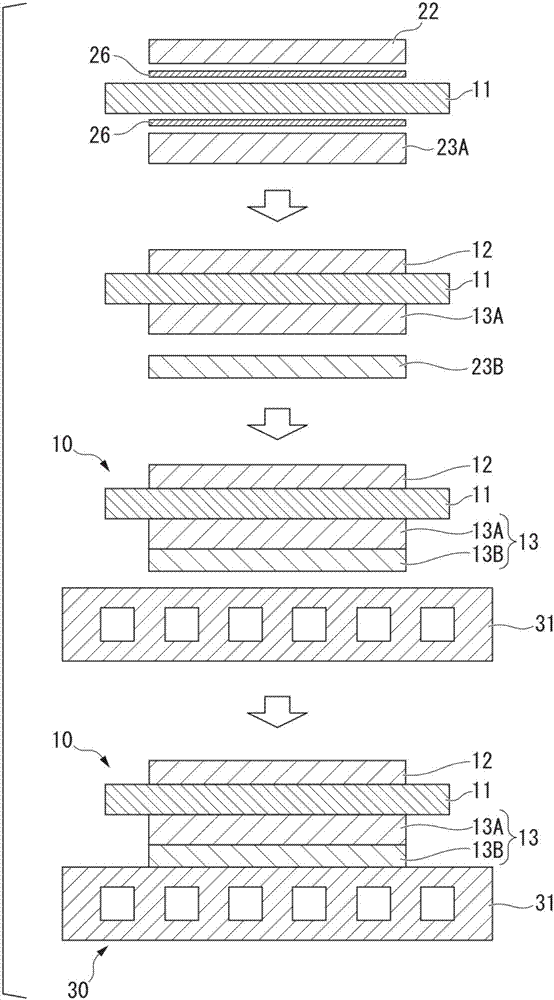

[0050] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

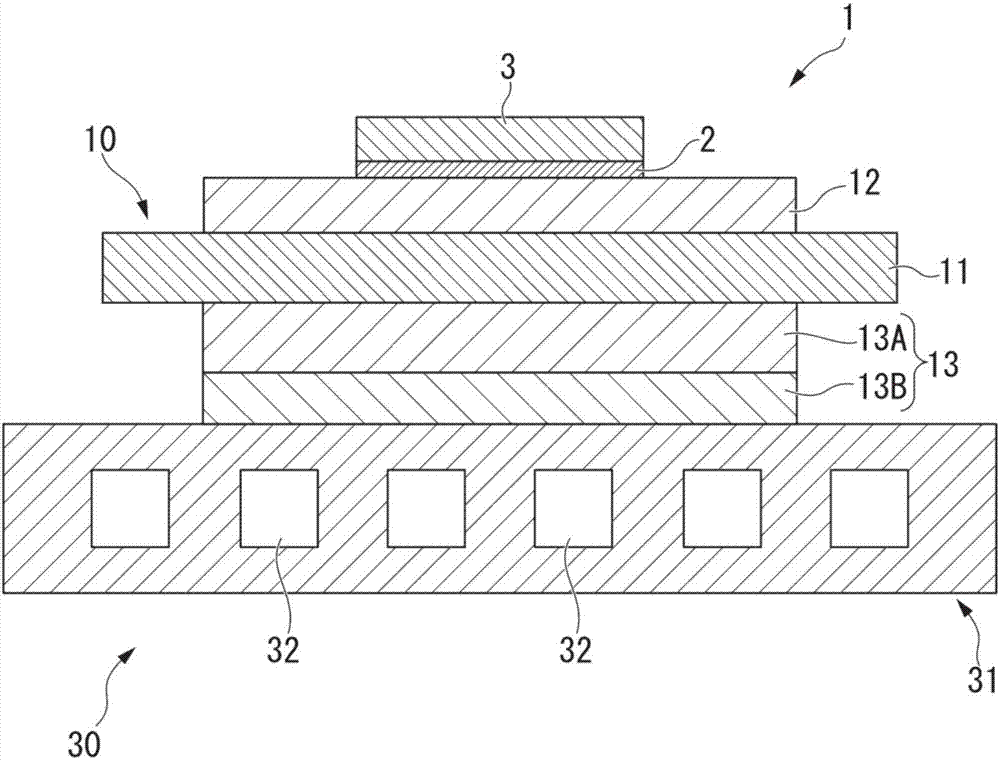

[0051] figure 1 A power module 1 using the power module substrate 30 with a heat sink according to the first embodiment of the present invention is shown in .

[0052] The power module 1 includes a power module substrate 30 with a heat sink and one side of the power module substrate 30 with a heat sink (in the figure 1 The upper surface in the middle) is the semiconductor element 3 bonded by the solder layer 2 .

[0053] The power module substrate 30 with heat sink includes the power module substrate 10 and the heat sink 31 bonded to the power module substrate 10 .

[0054] The power module substrate 10 includes a ceramic substrate 11 constituting an insulating layer, and is arranged on one surface of the ceramic substrate 11 (in figure 1 The circuit layer 12 in the center is the upper surface) and the metal layer 13 is arranged on the other surface of the ceramic su...

no. 2 approach

[0100] Next, a heat sink according to a second embodiment of the present invention will be described. Figure 5 A heat sink 101 according to a second embodiment of the present invention is shown in .

[0101] The heat sink 101 has a heat sink main body 110 and one side laminated on the heat sink main body 110 (in the Figure 5 A copper component layer 118 made of copper or a copper alloy. Such as Figure 7 As shown, in the present embodiment, the copper component layer 118 is formed by joining a copper plate 128 made of an oxygen-free copper rolled plate.

[0102] A flow path 111 through which a cooling medium flows is provided in the radiator main body 110 . The heat sink main body 110 is made of an aluminum alloy having a Si concentration in the range of 1% by mass to 25% by mass, specifically ADC3, which is an aluminum alloy for die-casting specified in JIS H 2118:2006. Moreover, this ADC3 is an aluminum alloy containing Si in the range of 9.0-11.0 mass %, and Mg in the...

Embodiment

[0132] Hereinafter, the results of confirmation experiments conducted to confirm the effects of the present invention will be described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com