High-strength pure gold material and preparation method thereof

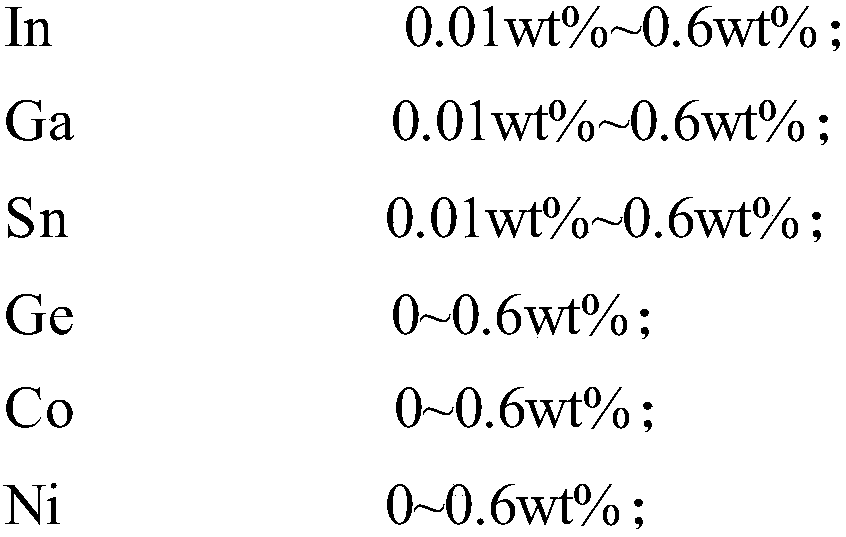

A high-strength, gold material technology, applied in the field of high-strength pure gold material and its preparation, can solve the problem that it is difficult to achieve large-scale and batch high-content gold material and its accessories and jewelry products. Alloy elements and gold are difficult to fuse and other problems, to achieve the effect of light weight, low loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

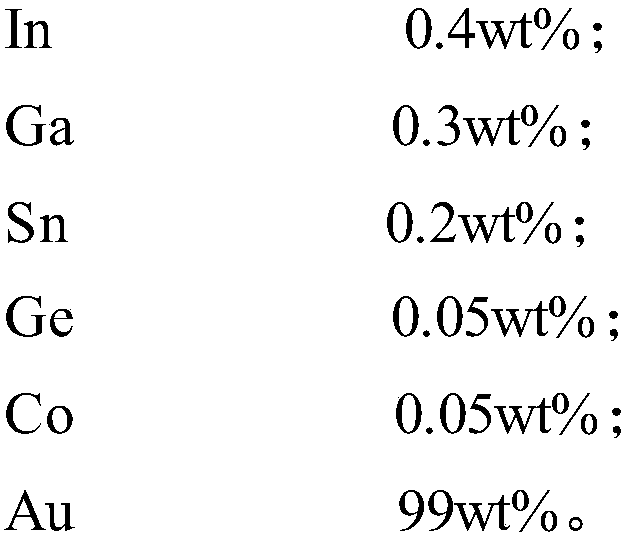

Embodiment 1

[0041] First, mix 0.4% indium, 0.3% gallium, 0.2% tin, 0.05% germanium and 0.05% cobalt, then add 99% high-purity gold (gold content 99.99%), and use vacuum induction melting method for melting, Put alloy elements and pure gold into the crucible for melting at one time. In order to ensure the uniformity of the sample, electromagnetic stirring is used in the smelting, and the sample is smelted twice, and then solidified to obtain the target pure gold material. The pure gold material was cast and cold-rolled into gold flakes with a thickness of 0.5mm. The gold content of the sample was tested by the fire assay method, and the hardness of the sample was measured by a microhardness tester. The obtained data are shown in Table 1:

[0042] Table 1 Example 1 pure gold material hardness test result

[0043] sample status

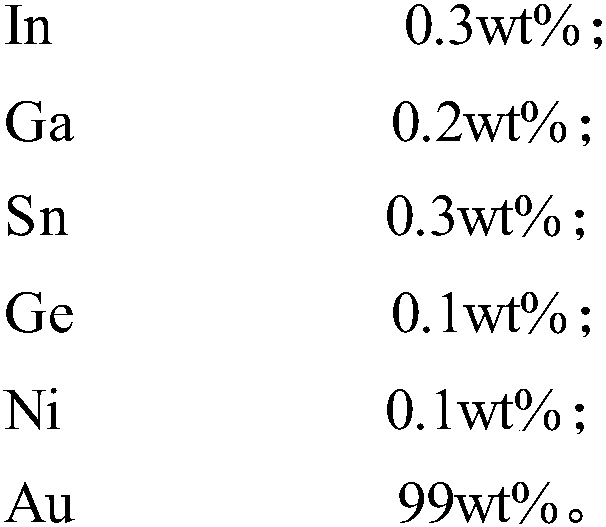

Embodiment 2

[0049] First, mix 0.3% indium, 0.2% gallium, 0.3% tin, 0.1% germanium and 0.1% nickel, then add 99% high-purity gold (99.99% gold content), and use an open induction furnace for melting , when smelting, add borax covering agent on the surface, wrap the alloy elements with pure gold sheets, and put them into the crucible for smelting together with gold. In order to ensure the uniformity of the sample, the sample was smelted twice, and a quartz rod was used for stirring during the smelting, and then solidified to obtain the target pure gold material. The pure gold material was cast and cold-rolled into gold flakes with a thickness of 0.5 mm. The gold content of the sample was tested by the fire assay method, and the hardness of the sample was measured by a microhardness tester. The obtained data are shown in Table 3:

[0050] Table 3 embodiment 2 solid gold material hardness test result

[0051] sample status

Embodiment 3

[0053] First, mix 0.2% indium, 0.4% gallium, 0.3% tin, 0.05% cobalt and 0.05% nickel, then add 99% high-purity gold (99.99% gold content), and use an open induction furnace for melting , when smelting, add borax covering agent on the surface, wrap the alloy elements with pure gold sheets, and put them into the crucible for smelting together with gold. In order to ensure the uniformity of the sample, the sample was smelted twice, and a quartz rod was used for stirring during the smelting, and then solidified to obtain the target pure gold material. The pure gold material was cast and cold-rolled into gold flakes with a thickness of 0.5mm. The gold content of the sample was tested by the fire assay method, and the hardness of the sample was measured by a microhardness tester. The obtained data are shown in Table 4:

[0054] Table 4 Example 3 pure gold material hardness test result

[0055] sample status

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com