Preparing method of zinc magnesium function gradient biological composite

A technology of functionally gradient and composite materials, applied in the field of preparation of functionally gradient biomaterials, can solve the problems of high brittleness of pure zinc, poor tensile strength and elongation, inferior mechanical properties to magnesium, etc., and achieve accurate and detailed data and bonding strength. High, avoids the effect of stress shadowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

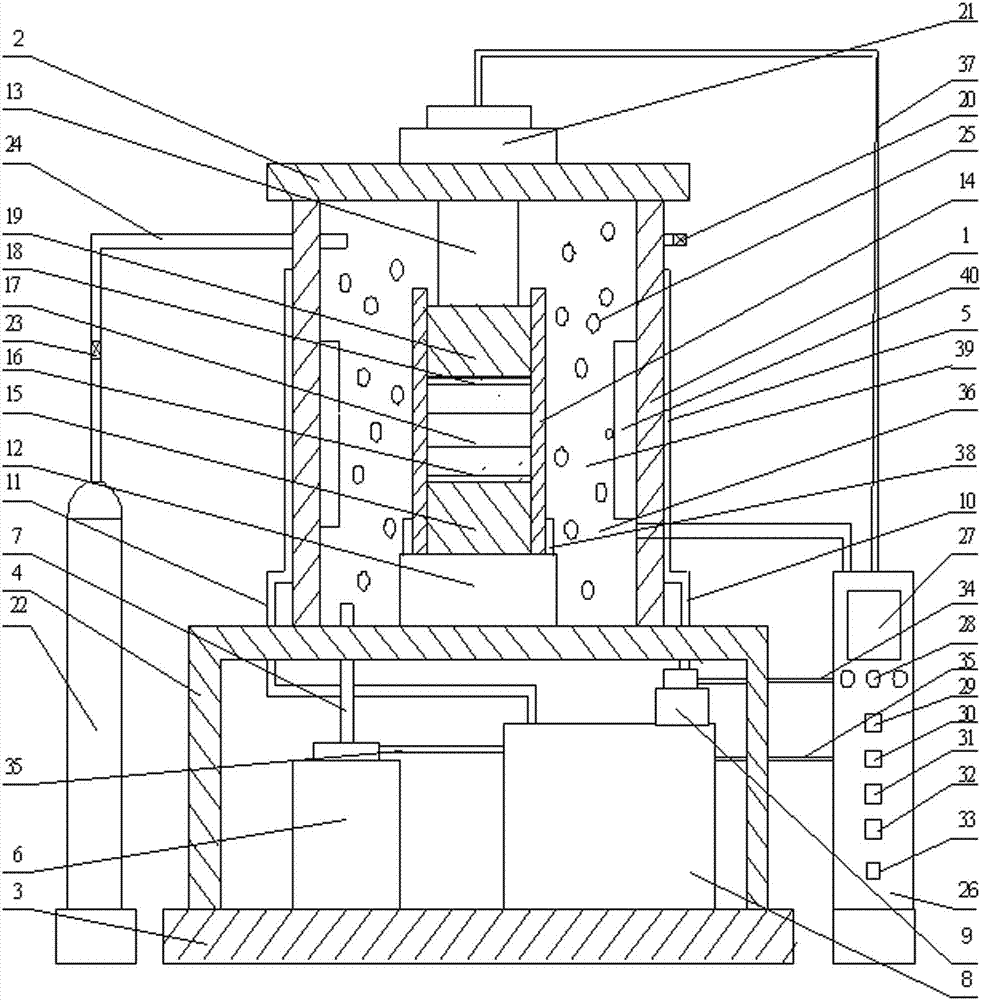

Image

Examples

Embodiment Construction

[0060] Its preparation consumption of the chemical substance material that this method uses is as follows: Take gram, millimeter, milliliter as unit of measurement

[0061] Zinc powder: 200g±0.01g

[0062] Magnesium powder: 100g±0.01g

[0063] HA powder: 100g±0.01g

[0064] Deionized water: H 2 O 3000mL±10mL

[0065] Graphite block: C 500mm×500mm×100mm

[0066] Graphite block: C 200mm×160mm×50mm

[0067] Graphite compact: C 200mm×160mm×50mm

[0068] Graphite paper: C 1000mm×1mm×500mm

[0069] Absolute ethanol: C 2 h 6 O 1000mL±10mL

[0070] Sandpaper: 400 mesh 300mm×0.5mm×200mm

[0071] In step (1), the chemical substances and materials used in the preparation should be selected, and the quality and purity should be controlled:

[0072] Zinc: solid powder 99.99%

[0073] Magnesium: solid powder 99.99%

[0074] Acetone: liquid liquid 99.9%

[0075] Deionized Water: Liquid Liquid 99.9%

[0076] Graphite block: solid block 98.5%

[0077] Graphite spacer: solid blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com