Preparation method for blue green light carbon quantum dot with pH response

A blue-green light carbon quantum and dot mixing technology, applied in the field of blue-green light carbon quantum dot preparation, can solve the problems of expensive raw materials, lengthy post-processing process, harsh reaction conditions, etc., to improve chemical and physical properties, significantly stimulate dependence The effect of sex, accurate and detailed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

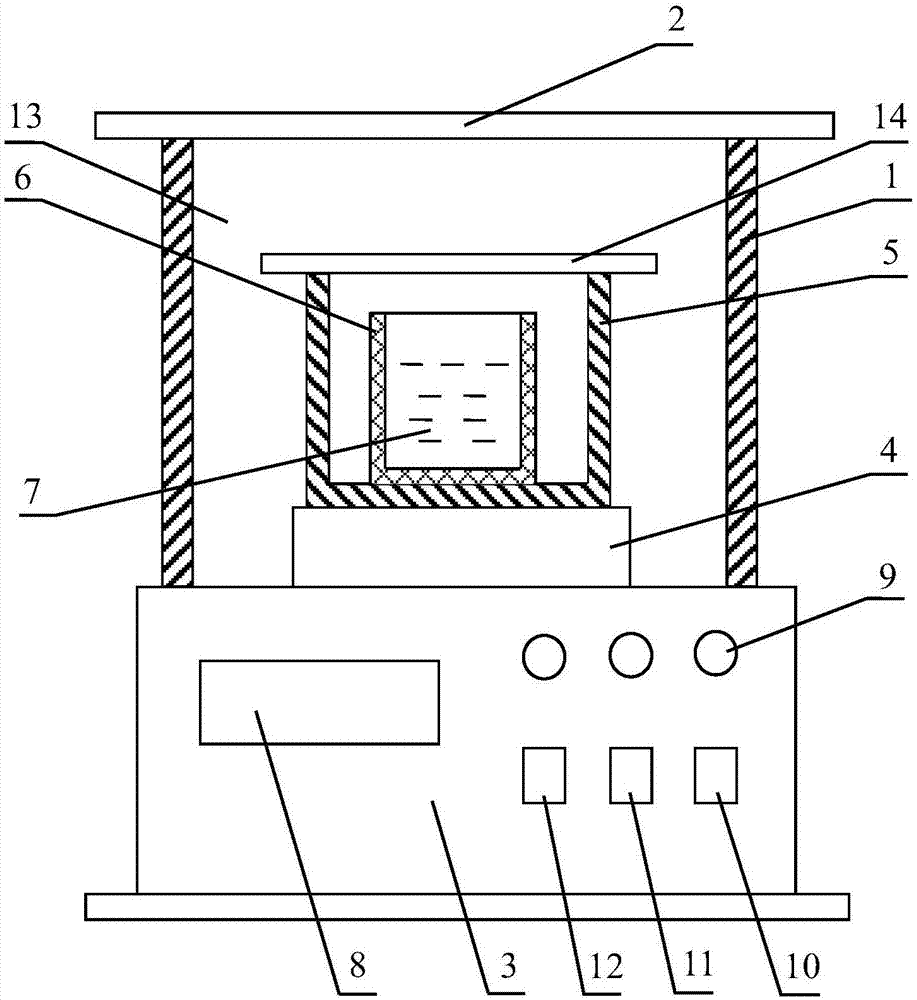

[0064] The preparation of the blue-green light carbon quantum dot mixture is carried out in the reactor, which is completed under the state of heating and hydrothermal synthesis;

[0065] The heating furnace 1 is vertical, the upper part of the heating furnace 1 is the furnace cover 2, the lower part is the first electric control box 3, the inside of the heating furnace 1 is a furnace chamber 13, and the inner bottom of the furnace chamber 13 is provided with a first workbench 4, Place reactor 5 on first workbench 4, place polytetrafluoroethylene container 6 in reactor 5, be mixed solution 7 in polytetrafluoroethylene container 6, reactor 5 is sealed by reactor lid 14; The control box 3 is provided with a first display screen 8 , a first indicator light 9 , a first power switch 10 , a heating temperature controller 11 , and a heating time controller 12 .

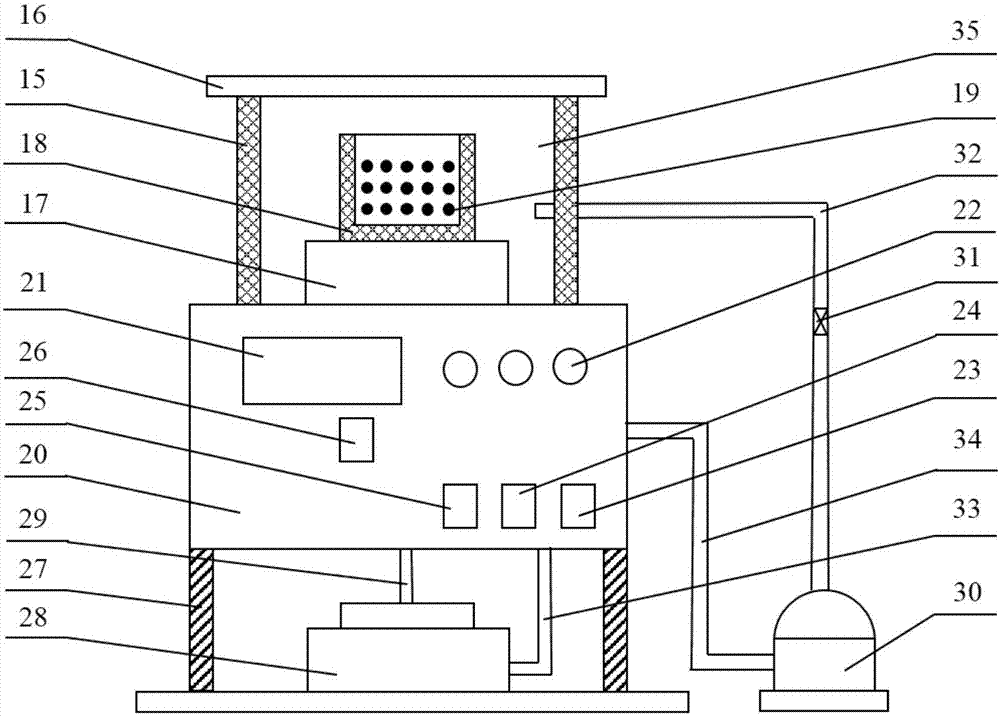

[0066] figure 2 As shown, it is the vacuum freeze-drying state diagram of blue-green light carbon quantum dots. The posi...

Embodiment 1

[0077] Measurement of pH Responsiveness of Blue-Green Light Carbon Quantum Dots

[0078] (1) Prepare 10 mL of blue-green carbon quantum dot mixture solution with pH=7

[0079] Weigh 0.1g±0.0001g of blue-green light carbon quantum dots, measure 4mL±0.0001mL of deionized water, add it into a beaker, stir and mix for 5min to form a mixed solution; transfer the mixed solution to a volumetric flask, and deionized water respectively Rinse the beaker with 1mL for 3 times, add the rinse solution into the volumetric flask, and then use 3mL of deionized water to make up to the volume to form 10mL of blue-green carbon quantum dot mixture solution with pH=7;

[0080] (2) Prepare 25 mL of aqueous hydrochloric acid solution of 1 mol / L

[0081] Measure 2.08mL±0.0001mL of hydrochloric acid with a concentration of 37.5%, 6mL±0.0001mL of deionized water, add them into a beaker, stir and mix for 5min to form a mixed solution, move the mixed solution into a volumetric flask, and moisten with 5mL...

Embodiment 2

[0089] Measurement of Photobleaching Resistance of Blue-Green Light Carbon Quantum Dots under Different UV Light Irradiation Times

[0090] (1) Prepare 10mL of blue-green carbon quantum dot mixture solution of 10mg / mL

[0091] Weigh 0.01g±0.0001g of blue-green light carbon quantum dots, measure 4mL±0.0001mL of deionized water, add it into a beaker, stir and mix for 5min to form a mixed solution, transfer the mixed solution to a volumetric flask, and use deionized water respectively Rinse the beaker with 1mL for 3 times, add the rinse solution into the volumetric flask, and then use 3mL of deionized water to make up to 10mL of 10mg / mL blue-green carbon quantum dot mixture;

[0092] (2) Take 3mL of 10mg / mL blue-green light carbon quantum dot mixture and place it in a light-transmitting cuvette, measure it with a fluorescence spectrometer, and obtain the original fluorescence spectrum;

[0093] (3) Put the cuvette into the black box three-purpose ultraviolet light analyzer, irra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com