Hydrophilic poly methyl methacrylate chip material, chip and its preparing method

A polymethyl methacrylate and chip material technology, which is applied in the field of micro-total analysis, can solve the problems of shedding of hydrophilic groups, complicated modification process, influence on repeatability, etc., and achieves improved hydrophilicity, simple process, and improved separation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

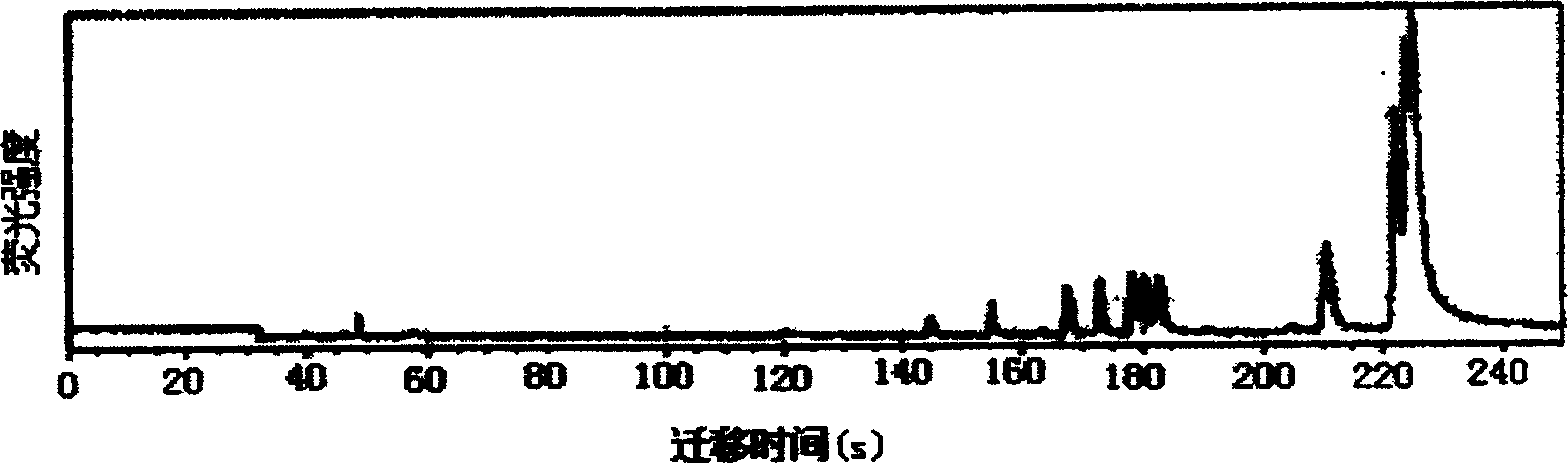

[0015] Example 1: φX-174 / HaeЩ digest DNA standard was separated on an unmodified PMMA chip.

[0016] Polymethyl methacrylate microfluidic chips were fabricated by conventional methods.

[0017] The φX-174 / HaeЩ digest DNA standard is separated on this PMMA chip: the standard concentration is 0.5ng / μL (142pM). The separation conditions were 1.5% HPMC in 100mM Tris / 100mM boric acid / 2mM EDTA, the dye concentration was 1μM SYTOX Orange, the separation length was 40mm, and the separation voltage was 270V / cm. The injection volume was 177pL. The separation profile of φX-174 / HaeЩ digest DNA standard on the unmodified PMMA chip is as follows: figure 1 shown.

Embodiment 2

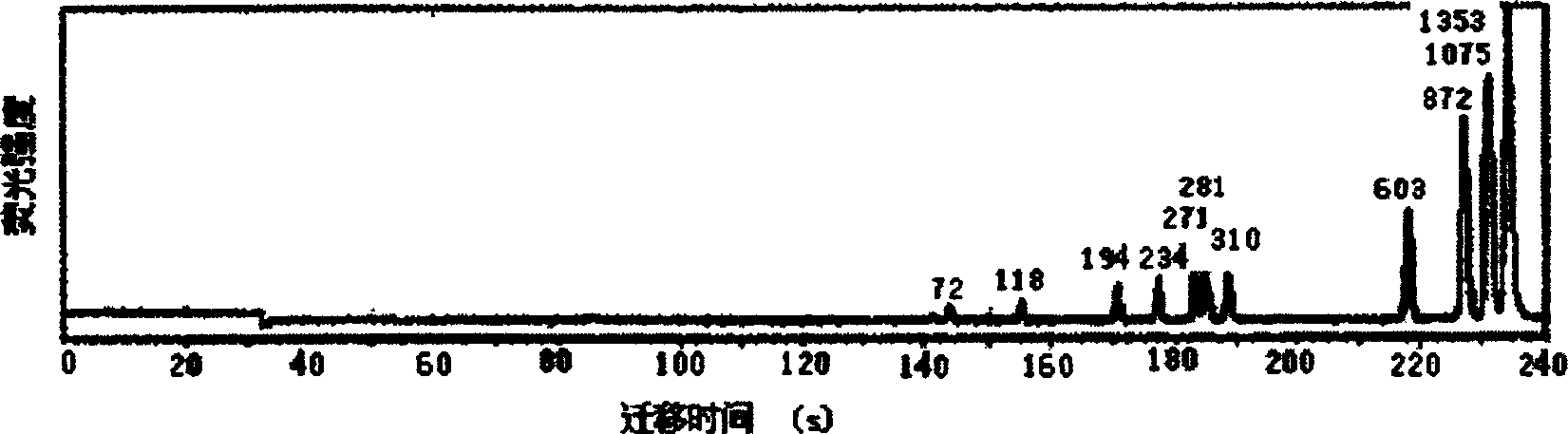

[0018] Example 2: φX-174 / HaeЩ digest DNA standard was separated on the PMMA chip modified by the patented method.

[0019] Adopt a kind of organic matter ABS plastic (acrylonitrile-butadiene-styrene Acrylonitrile Butadiene Styrene) with good hydrophilicity to add ABS plastic in PMMA before making polymethyl methacrylate microfluidic chip, make in the raw material The content of ABS plastic is 5%, and then injection molded into chips according to conventional methods.

[0020] The φX-174 / HaeЩ digest DNA standard is separated on the PMMA chip modified by this patented method: the concentration of the standard is 0.5ng / μL (142pM). The separation conditions were 1.5% HPMC in 100mM Tris / 100mM boric acid / 2mM EDTA, the dye concentration was 1μM SYTOX Orange, the separation length was 40mm, and the separation voltage was 270V / cm. The injection volume was 177pL. The separation profile of φX-174 / HaeЩ digest DNA standard on the modified PMMA chip is as follows: figure 2 shown.

[002...

Embodiment 3

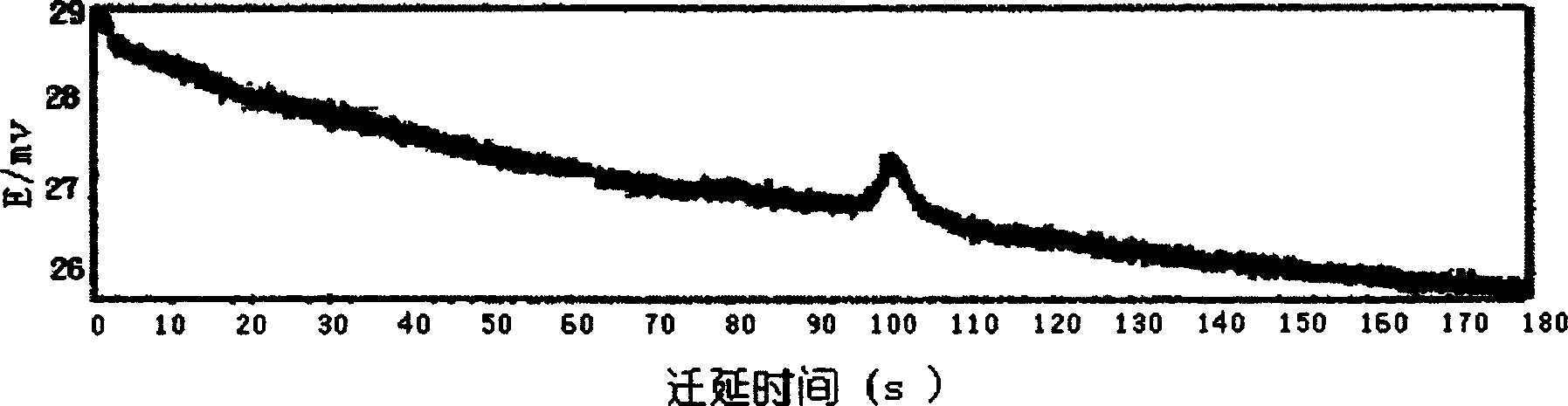

[0023] Example 3: Detection of the fluorescent dye rhodamine 6G by using the modified PMMA chip of this patent.

[0024] A polymethyl methacrylate microfluidic chip was fabricated according to Example 2.

[0025] Utilize this modified PMMA chip to detect the minimum detection limit chip electrophoresis pattern of fluorescent dye rhodamine 6G as follows image 3 shown.

[0026] In terms of detection sensitivity, under the same conditions to detect the fluorescent dye rhodamine 6G, the sensitivity of this embodiment can reach 6.67 × 10 -13 mol / L, while the detection sensitivity of ordinary polymethyl methacrylate microfluidic chip is 1.0×10 -10 mol / L, the sensitivity of this embodiment is improved by more than 100 times in comparison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com