A Precipitation Hardening Stainless Steel with Multicomponent Composition Based on High Entropy Effect

A technology of precipitation hardening and stainless steel, which is applied in the field of design and development of new precipitation hardening stainless steel components with multi-component components, can solve the problems of undiscovered age hardening performance, improve solid solution strengthening effect, improve corrosion resistance, and increase lattice distortion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

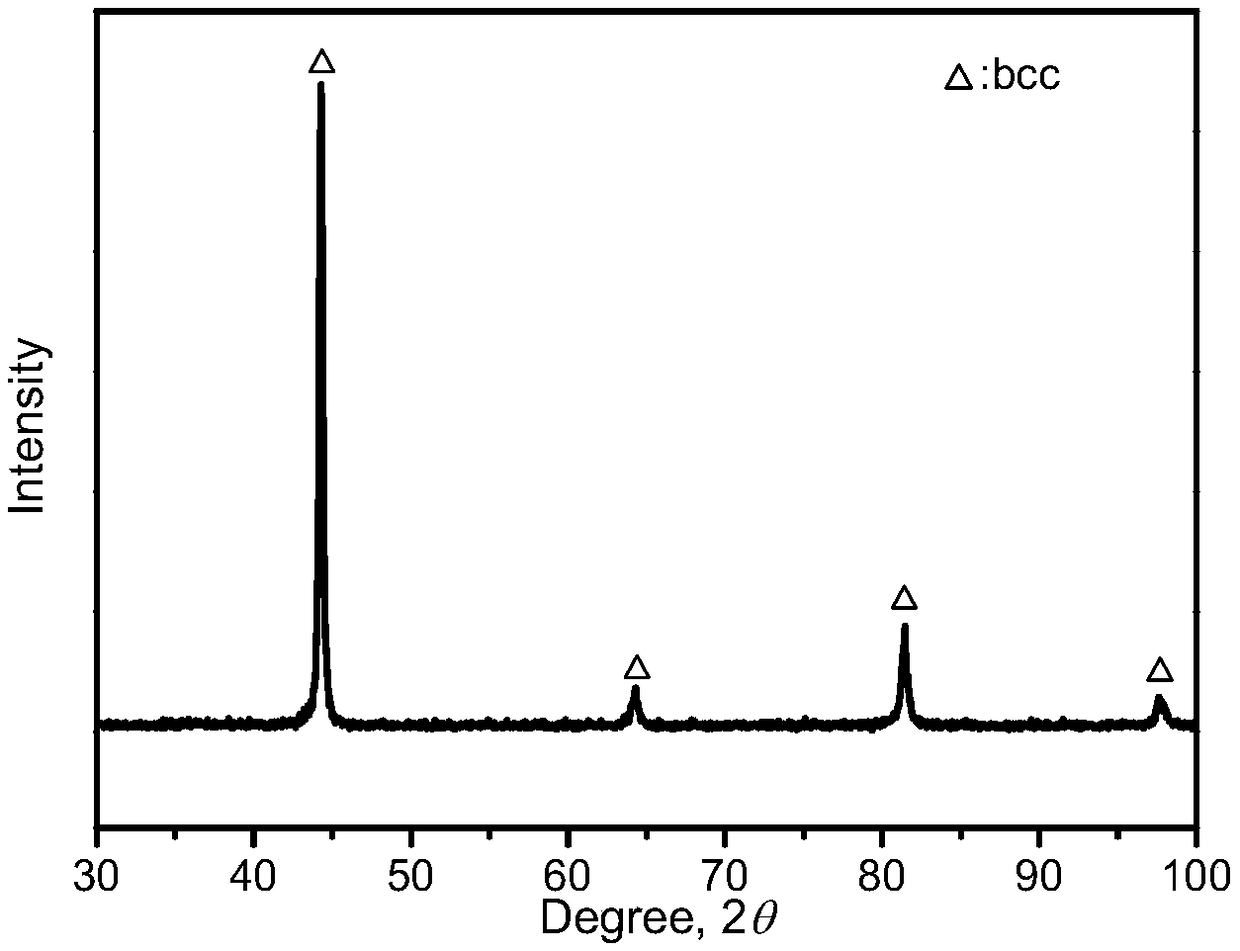

[0020] A multi-component precipitation-hardening stainless steel based on the high-entropy effect. The main component given in this example is configured as Fe according to the molar percentage 65 Cr 13 Ni 3.16 co 3.16 mn 3.16 Mo 3.16 al 3.16 Ti 3.16 Cu 3 , do not add carbon, the purity of the selected alloy elements to add raw materials is ≥ 99%, intercept an appropriate amount of raw materials from the base metal, use mechanical grinding to remove the oxide skin on the surface of the raw metal, and then the components designed in this embodiment are composed of The molar ratio is converted into a weight ratio, and the raw materials are weighed by an electronic balance with an induction capacity of 0.1 mg, and mixed uniformly. The total weight of the mixed raw materials is about 30g. Subsequently, the configured raw materials were placed in the copper crucible in the WK non-consumable vacuum electric arc furnace developed by Shenyang Vacuum Technology Research Institu...

Embodiment 2

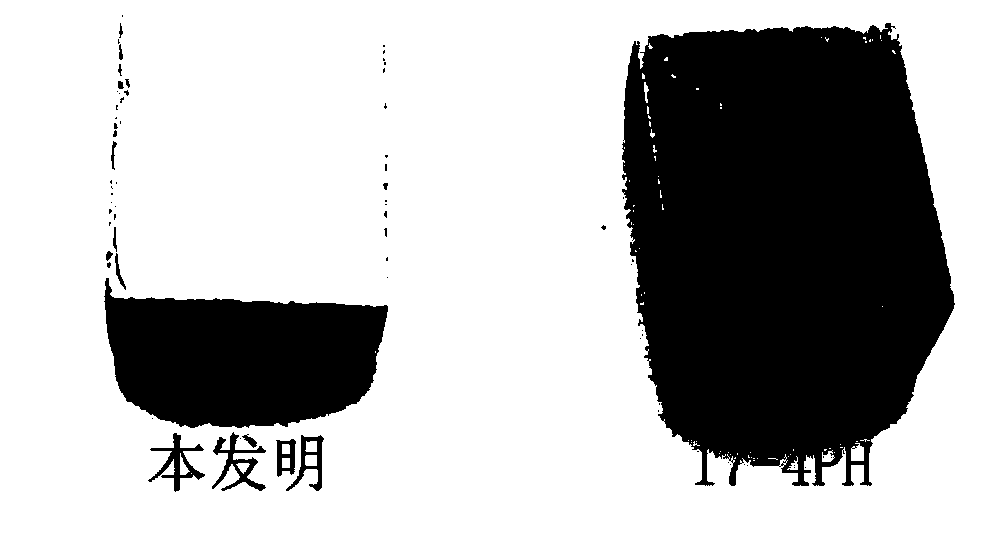

[0026] A multi-component precipitation-hardening stainless steel based on the high-entropy effect. The main components given in this example are shown in Table 2 Nos. 1-3, and No. 2 and No. 3 have added trace elements of C and Nb on the basis of No. 1. The purity of the raw materials for the capacity of the selected alloying elements is greater than or equal to 99%, and the smelting preparation and aging treatment methods are as described in Example 1. As can be seen from the properties described in Table 2, the maximum aging hardness of No. 1-3 samples is higher than that of the 17-4PH (0Cr17Ni4Cu4Nb) sample maximum aging hardness 476HV prepared by the same smelting and aging process, adding a small amount of C and Nb is beneficial to further Improve the aging hardness of stainless steel. The corrosion resistance immersion test shows that the corrosion resistance of No. 1-3 samples is higher than that of No. 17-4PH samples.

Embodiment 3

[0028] A multi-component precipitation-hardening stainless steel based on the high-entropy effect. The main components given in this example are shown in No. 4-6 in Table 2. No. 4-6 mainly changes the Fe content on the basis of No. 1 composition, and changes the Cr content accordingly. Element content, No. 6 did not add Cu. The purity of the raw materials for the capacity of the selected alloying elements is greater than or equal to 99%, and the smelting preparation and aging treatment methods are as described in Example 1. It can be seen from the properties described in Table 2 that the maximum aging hardness of No. 4-6 samples is higher than that of the 17-4PH (0Cr17Ni4Cu4Nb) sample prepared by the same smelting and aging process, the maximum aging hardness is 476HV. The corrosion resistance immersion test shows that the corrosion resistance of No. 4, No. 5 and No. 6 samples is higher than that of the 17-4PH sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com