Carbon fiber reinforced polymer matrix composite board and preparing method thereof

A composite plate and polymer technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as large labor force, low production efficiency, and long curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put the short carbon fiber in 65wt% nitric acid solution and soak for 2h. Rinse with deionized water until neutral and dry for later use.

[0031] (2) Soak the carbon fibers obtained in step (1) in a silane solution with a volume concentration of 35% for 3 hours, rinse with water until neutral, and dry in a vacuum oven at 120° C. for 5 hours to obtain modified carbon fibers.

[0032] (3) Dry the polylactic acid fiber in an oven at 85° C. for 12 h to remove the adsorbed moisture to prevent shear degradation.

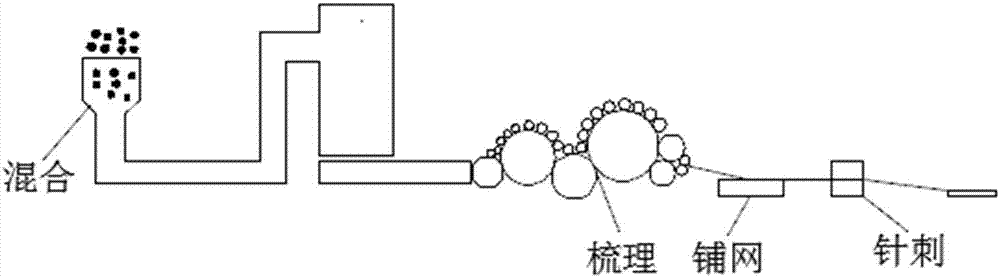

[0033] (4) Mix the modified carbon fiber obtained in step (2) with the polylactic acid obtained in step (3) in a ratio of 10:90. Comb the fiber raw material that has been initially opened and mixed into a thin net composed of single fibers. The thin web output from the carding machine is laid up into a fiber web of a certain thickness by cross-laying into a web, and then needle-punched into a felt.

[0034] (5) First, clean the inner sides of the two molds. ...

Embodiment 2

[0036] (1) Dry the polylactic acid in an oven at 50°C for 24 hours to remove the adsorbed moisture. Then polylactic acid is melted and extruded through a ring-shaped mold, pulled up by a coiled roller, air is introduced into the polymer tube to expand, and cooled within a certain distance from the mold exit to form a film with a thickness of 0.3mm. From the hopper to the die, the temperature of the single-screw extruder was set at 160, 180, 190 and 190 °C, respectively.

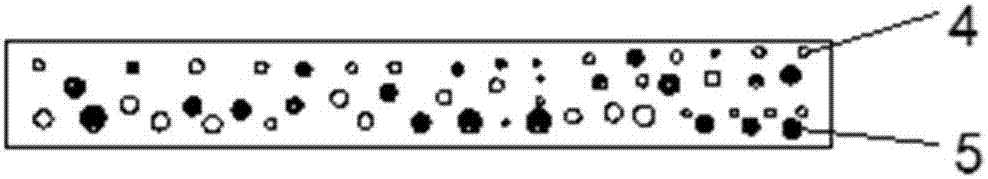

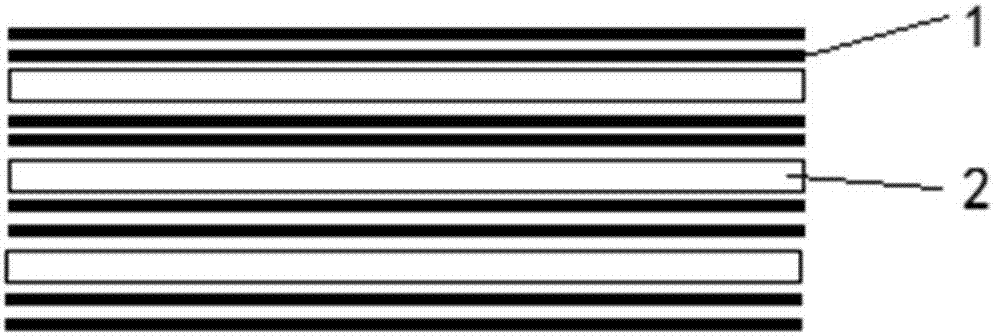

[0037] (2) Two layers of carbon fiber non-woven fabric and the PLA film obtained in step (1) are alternately stacked to 2 cm, and then placed between two polytetrafluoroethylene sheets, and placed in a metal counter-mold with the inner side wiped clean. When closing the mold, the fast speed is 8m / min, and when the distance between the male and female molds is 8cm, the slow speed is changed to 3m / min. Heat to 200°C, pressurize to 150MPa, hold the pressure for 5 minutes, solidify and form, release the pressure...

Embodiment 3

[0039] (1) Place short carbon fibers in 70%wt potassium permanganate solution and soak for 2h. Rinse with deionized water until neutral and dry for later use.

[0040](2) Soak the carbon fibers obtained in step (1) in a silane solution with a volume fraction of 30% for 2 hours, rinse with water until neutral, and dry in a vacuum oven at 120° C. for 5 hours to obtain modified carbon fibers.

[0041] (3) Carding the fiber raw materials that have been preliminarily opened and mixed into a thin web composed of single fibers, laying up a fiber web of a certain thickness by cross-laying to form a web, and then needling to form a felt.

[0042] (4) Dry the polylactic acid in an oven at 50°C for 24h to remove the adsorbed moisture. Then polylactic acid is melted and extruded through a ring-shaped mold, pulled up by a coiled roller, air is introduced into the polymer tube to expand, and cooled within a certain distance from the mold exit to form a film with a thickness of 0.3mm. From...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com