Ceramic/metal composite material wear-resistant lining plate and preparation method thereof

A metal composite material and wear-resistant liner technology, which is applied in the material field to achieve the effects of cost reduction, convenient maintenance and good economic applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

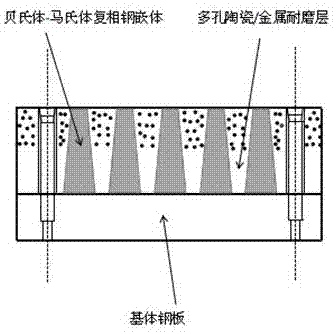

[0034] Embodiment 1: as Figure 1~3 As shown, a ceramic / metal composite wear-resistant liner includes a bainite-martensitic composite steel inlay, a porous ceramic / metal wear-resistant layer, a base steel plate, and the porous ceramic / metal wear-resistant layer is provided with embedded holes The bainite-martensite composite steel inlay is fixed in the embedding hole of the porous ceramic / metal wear-resistant layer, and the porous ceramic / metal wear-resistant layer is fixedly connected to the base steel plate.

[0035] The thickness of the porous ceramic / metal wear-resistant layer is 200mm, and the depth of the embedded hole is 200mm; the bainite-martensitic multiphase steel inlay is a circular platform, the height of the circular platform is 200mm, the diameter of the upper bottom surface is 30mm, and the diameter of the lower bottom surface is 31mm, the embedded hole matches the round table.

[0036] The porous ceramic / metal wear-resistant layer is provided with threaded th...

Embodiment 2

[0048] Embodiment 2: as Figure 1~3 As shown, a ceramic / metal composite wear-resistant liner includes a bainite-martensitic composite steel inlay, a porous ceramic / metal wear-resistant layer, a base steel plate, and the porous ceramic / metal wear-resistant layer is provided with embedded holes The bainite-martensite composite steel inlay is fixed in the embedding hole of the porous ceramic / metal wear-resistant layer, and the porous ceramic / metal wear-resistant layer is fixedly connected to the base steel plate.

[0049] The thickness of the porous ceramic / metal wear-resistant layer is 180mm, and the depth of the embedding hole is 180mm; the bainite-martensitic composite phase steel inlay is a square platform, the height of the square platform is 180mm, and the side length of the upper bottom surface is 40mm , the side length of the lower bottom surface is 41mm, and the embedded hole matches the square platform.

[0050] The porous ceramic / metal wear-resistant layer is provided...

Embodiment 3

[0062] Embodiment 3: as Figure 1~3 As shown, a ceramic / metal composite wear-resistant liner includes a bainite-martensitic composite steel inlay, a porous ceramic / metal wear-resistant layer, a base steel plate, and the porous ceramic / metal wear-resistant layer is provided with embedded holes , the bainite-martensite composite steel inlay is fixed in the embedded hole of the porous ceramic / metal wear-resistant layer, and the porous ceramic / metal wear-resistant layer is fixedly connected to the base steel plate;

[0063] The thickness of the porous ceramic / metal wear-resistant layer is 170mm, and the depth of the embedded hole is 170mm; the bainite-martensitic composite phase steel inlay is a hexagonal platform, the height of the hexagonal platform is 170mm, and the side length of the upper bottom surface is 45mm , the side length of the lower bottom is 46mm, and the embedded hole matches the hexagonal platform;

[0064] The porous ceramic / metal wear-resistant layer is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com