Method for preparing powder metallurgy copper-based friction material through adhesion process

A powder metallurgy and friction material technology, which is applied in the field of copper-based high-speed train brake pads prepared by powder metallurgy technology, can solve the problems of uneven compaction stress distribution, uneven porosity distribution, and unstable friction coefficient, etc., and achieve good friction Wear performance, reduced pressure gradient, uniform density distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

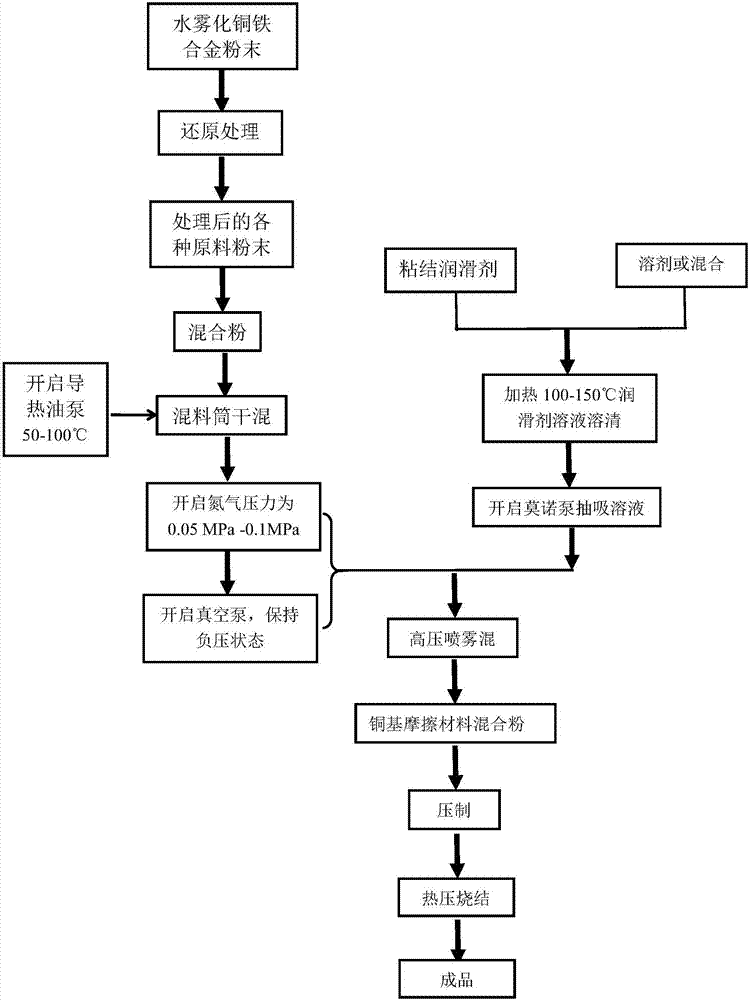

Method used

Image

Examples

Embodiment 1

[0017] 1. Prepare raw materials: the mass ratio is 60% pure electrolytic copper powder (150 μm), 7% tin powder (25 μm), 7% iron powder (25 μm), 3% nickel powder (25 μm), 5% silicon dioxide powder ( 25μm), 2% bismuth powder, 7% graphite powder, 2% molybdenum disulfide, 7% mullite;

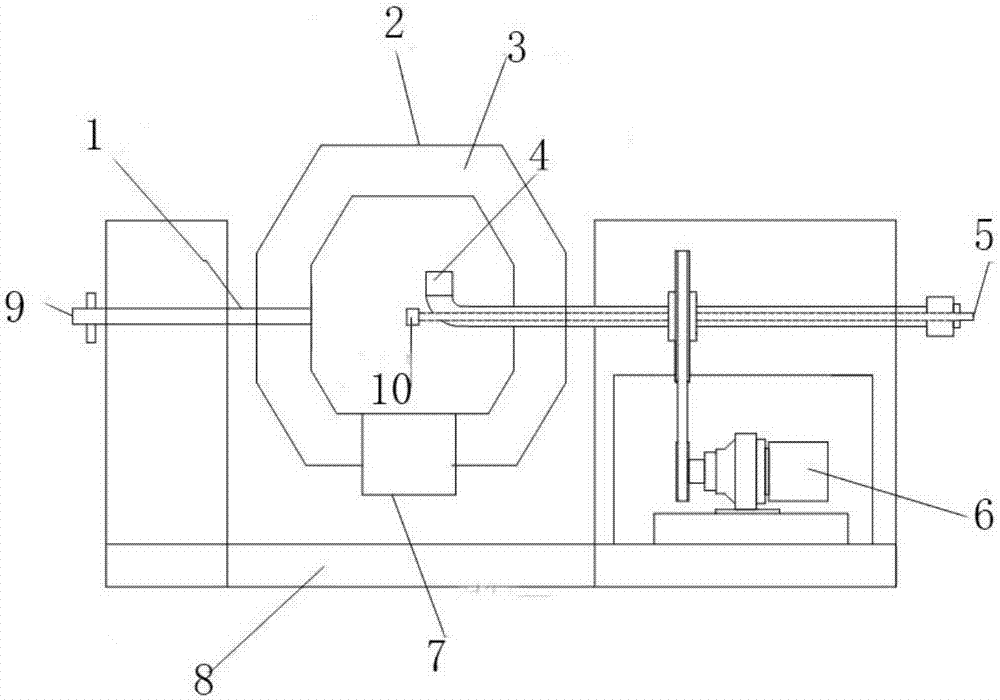

[0018] 2. Pour the above powder into the improved double-cone mixer. The mixing cylinder rotates continuously to stir the material. The high-pressure gas pressure is 0.1MPa. The sprayed adhesive lubricant solution forms a mist, which is fully mixed with the stirred material. Contact, mixing for 5 hours;

[0019] 3. Cold press the uniformly mixed powder in a mold with a pressure of 400MPa;

[0020] 4. Sinter the cold green body in a hot-press sintering furnace, heat it to 950°C, sinter in a hydrogen-nitrogen mixed gas, keep it warm for 80 minutes, and keep the hot-pressing pressure at 2MPa constant;

[0021] 5. Cool to below 100°C and take out, keep the pressure constant during the cooling process....

Embodiment 2

[0023] 1. Prepare raw materials: the mass ratio is 65% pure electrolytic copper powder (130 μm), 7% tin powder (25 μm), 7% iron powder (25 μm), 3% nickel powder (25 μm), 2% silicon dioxide powder ( 25μm), 7% graphite powder, 2% molybdenum disulfide, 7% mullite;

[0024] 2. Pour the above powder into the improved double-cone mixer. The mixing cylinder rotates continuously to stir the material. The high-pressure gas pressure is 0.08MPa. The sprayed adhesive lubricant solution forms a mist, which is fully mixed with the stirred material. Contact, mixing for 6 hours;

[0025] 3. Cold press the uniformly mixed powder in a mold with a pressure of 400MPa;

[0026] 4. Sinter the cold green body in a hot-press sintering furnace, heat it to 900°C, sinter it in a hydrogen-nitrogen mixed gas, keep it warm for 100 minutes, and keep the hot-pressing pressure constant at 2.5MPa;

[0027] 5. Cool to below 100°C and take out, keep the pressure constant during the cooling process.

Embodiment 3

[0029] 1. Prepare raw materials: the mass ratio is 70% pure electrolytic copper powder (120 μm), 7% tin powder (18 μm), 4% iron powder (18 μm), 3% nickel powder (18 μm), 2% silicon dioxide powder ( 18μm), 7% graphite powder, 2% molybdenum disulfide, 5% mullite;

[0030] 2. Pour the above powder into the improved double-cone mixer. The mixing cylinder rotates continuously to stir the material. The high-pressure gas pressure is 0.06MPa. The sprayed adhesive lubricant solution forms a mist, which is fully mixed with the stirred material. Contact, mixing for 7 hours;

[0031] 3. The uniformly mixed powder is cold-pressed, and the pressure is 450MPa;

[0032] 4. Sinter the cold green body in a hot-press sintering furnace, heat it to 850°C, sinter it in a hydrogen-nitrogen mixed gas, keep it warm for 120 minutes, and keep the hot-pressing pressure at 3MPa constant;

[0033] 5. Cool to below 100°C and take out, keep the pressure constant during the cooling process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com