Low-modulus single-component polyurethane sealing gum for hydraulic engineering, and production method thereof

A polyurethane sealant, low-modulus technology, used in polyurea/polyurethane adhesives, adhesives, epoxy resin adhesives, etc., can solve the problems of weak bonding of inorganic materials, unfriendly environment, and long curing time. It can achieve the effect of good anti-ice pulling and ice pushing effect, convenient construction and enhanced bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Low modulus one-component polyurethane sealant for hydraulic engineering,

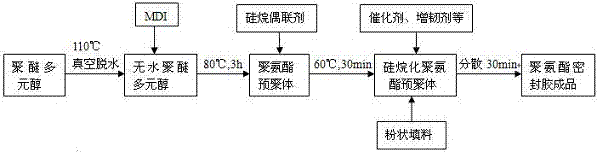

[0025] The preparation method of above-mentioned hydraulic engineering with low modulus one-component polyurethane sealant comprises the following steps:

[0026] (1) Weigh each component according to the above weight ratio, heat polyether polyol (330N) and polyether polyol (DL-2000) to 110°C, and dehydrate for 2 hours to form anhydrous polyether polyol;

[0027] (2) Then add diphenylmethane diisocyanate (MDI), and then add a part of the toughening agent to reduce the four-line oil at a constant temperature of 80°C for 3 hours to obtain a PU prepolymer;

[0028] (3) Add a silane coupling agent (KH-590) after cooling down to 60°C for 30 minutes to obtain a SPU prepolymer;

[0029] (4) Finally, add powdered filler, catalyst (T-12), and remaining toughening agent (same as the type of toughening agent added earlier, all of which can activate plasticizing effect, and the addition of the previous pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com