Supported noble metal catalyst with coating structure and its preparation method and application in liquid-phase catalytic reduction of cr(ⅵ)

A technology of precious metal catalysts and coating structures, applied in catalyst protection, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems that impurity ions cannot be directly reused, the expected effect cannot be achieved, and the resin is easily polluted , to achieve good economic and environmental benefits, good catalytic performance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A supported Pd metal catalyst with a coating structure and preparation thereof. The catalyst includes Pd-supported multi-walled carbon nanotubes Pd / MWCNT, the Pd loading is 1% (mass percentage), and the surface is coated with nitrogen doping Carbon coating.

[0045] The catalyst with coated structure was prepared according to the following steps:

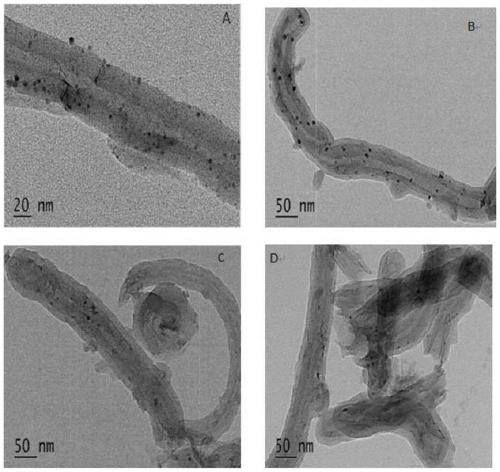

[0046] (1) First, the multi-walled carbon nanotubes (MWCNT) and the Pd salt solution are mixed and stirred, and supported by the dipping method to obtain supported Pd / MWCNT, wherein the Pd loading amount is 1% wt. The transmission electron microscope image of Pd / MWCNT is as follows figure 1 As shown in (A), it can be seen that the precious metal particles are uniformly dispersed on the surface of the multi-walled carbon nanotubes. According to statistics, the average particle size of the precious metal is about 3.73 nm.

[0047] (2) Then, disperse the Pd / MWCNT into a Tris (Tris(Trishydroxymethylaminomethane)) buffer solution with a...

Embodiment 2

[0055] In addition, the above-prepared Pd / MWCNT and Pd / MWCNT@CN series catalysts are used to carry out liquid phase catalytic reduction of Cr(Ⅵ) in water in a cyclic reaction (specifically as Image 6 Shown). The catalyst concentration is 0.325g / L, the initial concentration of Cr(Ⅵ) is 0.5mM, the pH of the reaction system is 2.0, the flow rate of hydrogen is 200ml / min, the reaction is under normal temperature and pressure for 2h, and the cycle reaction is four times. The deactivation rate is all within Below 5%, and with the increase of the coating amount, the stability is also significantly improved. The activity of the source material after four cycles is significantly reduced, and the initial activity inactivation rate is 92.5%. The comparison shows that the stability of the catalyst with the coated structure is obviously improved.

Embodiment 3

[0057] The preparation method of the supported Pd metal catalyst with the coating structure is the same as that of Example 1, and the catalyst prepared in this example is used for the liquid phase catalytic reduction reaction of Cr(VI). The catalyst adopts Pd / MWCNT@2CN, and its concentration is 0.125g / L, 0.225g / L, 0.325g / L, 0.375g / L, the initial concentration of Cr(Ⅵ) is 0.5mM, the reaction pH is 2.0, and the hydrogen flow rate 200ml / min, react for 2h at room temperature and pressure, such as Figure 7 Shown are the initial activity curves of Pd / MWCNT@2CN with different catalyst dosages. The initial activity of the catalyst is basically maintained at 8mM / (gcat.h), indicating that there is no mass transfer resistance in the reaction system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com