Temperature controllable switching type nano-filtration membrane and preparation method thereof

A nanofiltration membrane and switch-type technology, which is applied in the field of temperature-controllable switch-type nanofiltration membrane and its preparation, can solve the problems of poor permeability and low functionality of carbon nanotube filter membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A method for preparing a temperature-controllable switchable nanofiltration membrane, comprising the steps of:

[0061] S1. Depositing a carbon nanotube array on a single crystal silicon wafer, the center line of the carbon nanotube channel is perpendicular to the plane where the single crystal silicon wafer is located;

[0062] S2. Place the monocrystalline silicon wafer with the carbon nanotube array prepared in step S1 in an airtight material so that the airtight material fills the gaps between the carbon nanotubes, and then place it in a vacuum drying oven solidify to form a composite film, and peel the composite film from the single crystal silicon wafer. Since the channel of the carbon nanotube may be sealed by an airtight material, it is necessary to remove the airtight material inside the carbon nanotube, specifically Use ultra-thin microtome to cut off the two ends of the composite film, so that the airtight material or impurities blocked at the end of the carb...

Embodiment 1

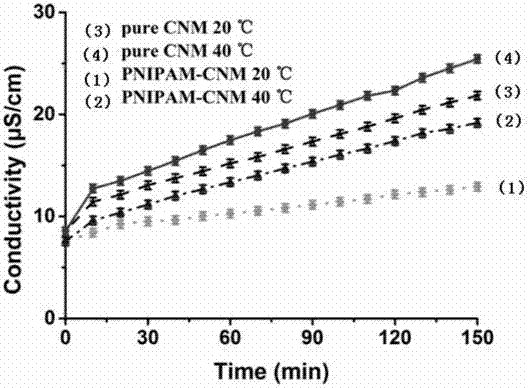

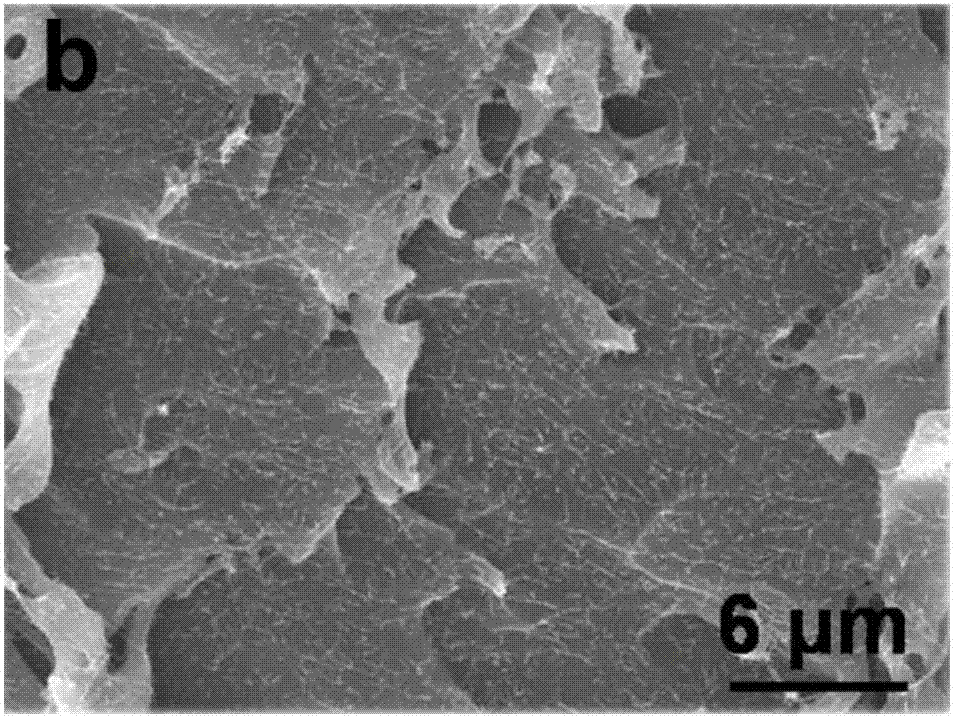

[0089] The temperature-controllable switchable nanofiltration membrane provided in this embodiment includes a filter membrane body and a carbon nanotube array that runs through the filter membrane body, the carbon nanotube array includes several carbon nanotubes arranged in parallel, and the carbon nanotubes The tube is grafted with a temperature-sensitive polymer poly-N-isopropylacrylamide material layer, and the temperature-sensitive polymer material layer is in a shrinking or stretching state as the temperature changes, so that the temperature-controllable switch nanofiltration The pore size of the membrane channel changes with temperature. The thickness of the nanofiltration membrane is 10 μm, and the pore diameter of the carbon nanotube is 14-16 nm. When the temperature is 20-40°C, the pore size of the nanofiltration membrane channel changes from small to large as the temperature rises.

[0090] The preparation method of the above-mentioned temperature-controllable switc...

Embodiment 2

[0131] The temperature-controllable switchable nanofiltration membrane provided in this embodiment includes a filter membrane body and a carbon nanotube array that runs through the filter membrane body, the carbon nanotube array includes several carbon nanotubes arranged in parallel, and the carbon nanotubes The tube is grafted with a temperature-sensitive polymer poly-N-isopropylacrylamide material layer, and the temperature-sensitive polymer material layer is in a shrinking or stretching state as the temperature changes, so that the temperature-controllable switch nanofiltration The pore size of the membrane channel changes with temperature. The thickness of the carbon nanotube nanofiltration membrane is 8 μm, and the pore diameter of the carbon nanotube is 14-16 nm. When the temperature is 20-40°C, the pore size of the nanofiltration membrane channel changes from small to large as the temperature rises.

[0132] The preparation method of the above-mentioned temperature con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com