Method for preparing metal superhydrophobic surface based on arc treatment

A super-hydrophobic surface and arc treatment technology, which is applied in arc welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problems of difficult cleaning of devices and influence on device functions, and achieve low environmental pollution, low cost and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

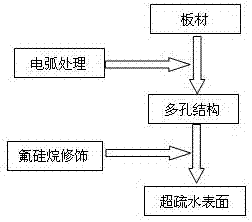

[0014] Such as figure 1 As shown, a method for preparing metal superhydrophobic surface based on arc treatment, the main steps are:

[0015] 1. Pre-treatment of arc treatment: Clean the surface of the flat plate with conventional methods such as alcohol and acetone for use.

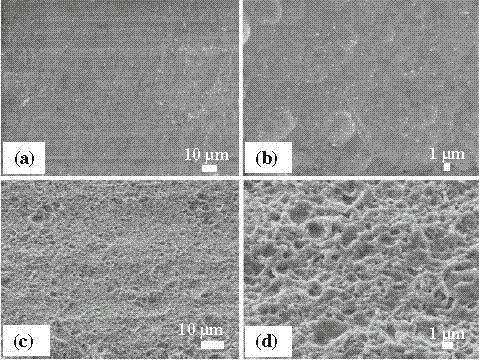

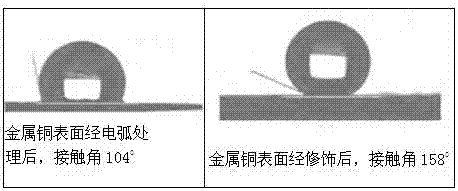

[0016] 2. Arc treatment: connect the plate processed by the conventional method to the positive and negative terminals of the welding machine, clamp the plate with the clip connected to the negative electrode, and aim the welding torch at the surface of the plate. The size of the arc is controlled by changing the welding current and voltage. After a period of time, a rough surface with a porous structure is formed.

[0017] 3. Fluorosilane modification treatment: Spin-coat fluorosilane hydrolyzate on the plate sample after chemical corrosion, and finally put the modified sample in an oven to dry to prepare a super-hydrophobic surface.

[0018] Taking the aluminum alloy plate as an example, the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com