Production formula and preparation method for elastic rotator

A production formula and technology of rotating body, applied in the field of production formula and preparation of elastic rotating body, can solve the problems of easy cracking, poor anti-aging performance, short service time, etc., achieve not easy cracking, good anti-aging performance, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

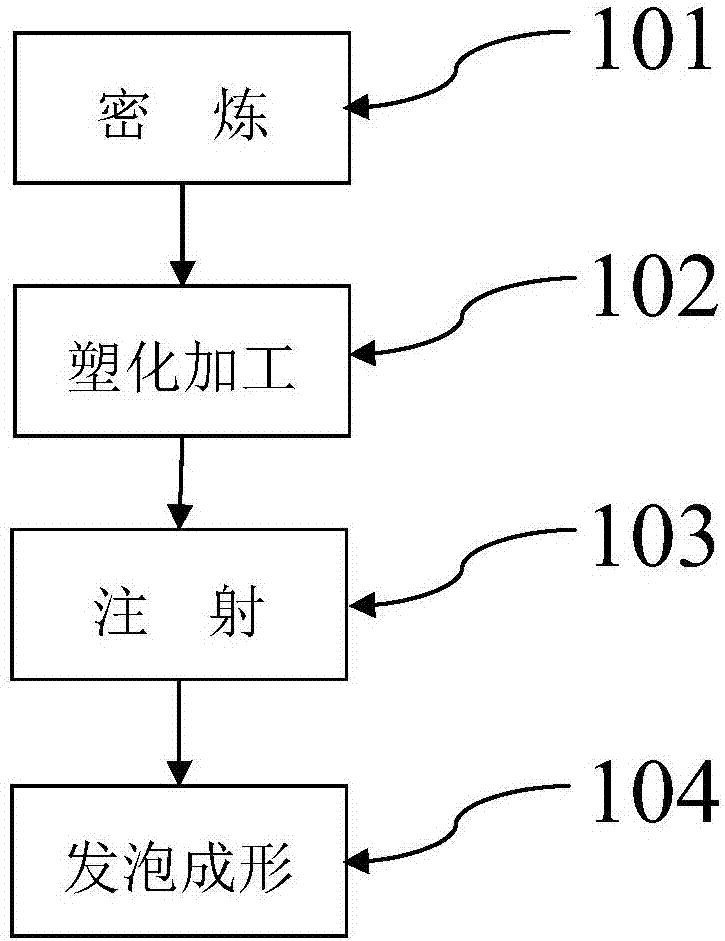

[0036] The preparation method of the elastic rotating body of the present invention is carried out according to the following specific steps:

[0037](1) Internal mixing: POE, EPDM rubber, anti-shrinkage agent, filler, EVA, stearic acid, zinc stearate, zinc oxide, crosslinking agent, foaming agent, flow agent, masterbatch pigment Add it into the internal mixer for mixing and stirring, then put the stirred material into the internal mixer for 8 to 12 minutes at a temperature of 80-100°C, put it into the open mixer for uniform tableting, and then granulate. Among them, the kneading temperature is controlled within the range of 45-65°C, the kneading time is controlled within the range of 5-8 minutes, and the granulation temperature is controlled within the range of 80-100°C;

[0038] (2) Plasticizing processing: input the above granulated materials into the barrel of the injection machine for plasticizing processing, and the temperature is controlled within the range of 70-100°C;...

Embodiment 1

[0046] A production recipe of an elastic rotating body of the present invention, calculated by weight, includes the following specific components: ethylene-octene copolymer (POE) 15%, EVA 50%, EPDM rubber 15%, anti-shrinkage agent E20 -58 7.5%, talcum powder with particle size ≤200nm 2%, stearic acid 0.3%, zinc stearate 0.7%, zinc oxide 1.5%, dicumyl peroxide DCP 1%, azodicarbonamide AC Foaming agent 2%, fatty acid ester 2%, masterbatch pigment 3%, the total weight is 100%.

[0047] Such as figure 1 Shown, the preparation method of a kind of elastic rotating body of the present invention is carried out according to the following specific steps:

[0048] (1) Internal mixing: POE, EPDM rubber, EVA, anti-shrinkage agent E20-58, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide DCP, azobis Add formamide AC foaming agent, fatty acid ester, and masterbatch into the internal mixer for mixing and stirring, and then mix the stirred materials with the internal m...

Embodiment 2

[0053] A production formula of an elastic rotating body of the present invention, calculated by weight, includes the following specific components: ethylene-octene copolymer (POE) 10%, EVA 60%, EPDM rubber 10%, anti-shrinkage agent E20 -58 5%, 2% talc powder with particle size ≤ 200nm, 1% calcium carbonate with particle size ≤ 200nm, 0.5% stearic acid, 1% calcium stearate, 2% zinc oxide, dicumyl peroxide DCP 0.7%, azodicarbonamide AC blowing agent 1.8%, fatty acid ester 2%, masterbatch pigment 4%, the total weight is 100%.

[0054] A kind of preparation method of elastic rotating body of the present invention is carried out according to the following specific steps:

[0055] (1) Internal mixing: POE, EPDM rubber, anti-shrinkage agent, talcum powder, calcium carbonate, EVA, stearic acid, calcium stearate, zinc oxide, dicumyl peroxide DCP, azobis Add the formamide AC foaming agent, fatty acid ester, and masterbatch into the internal mixer for mixing and stirring, and then mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com