Production method for seamless pure-calcium core-spun yarn

A pure calcium cored wire and production method technology, applied in the field of cored wire, can solve the problems of high rejection rate, small advantages and high production technical requirements, reduce the rejection rate and production cost, prevent calcium gasification loss, production Technically demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

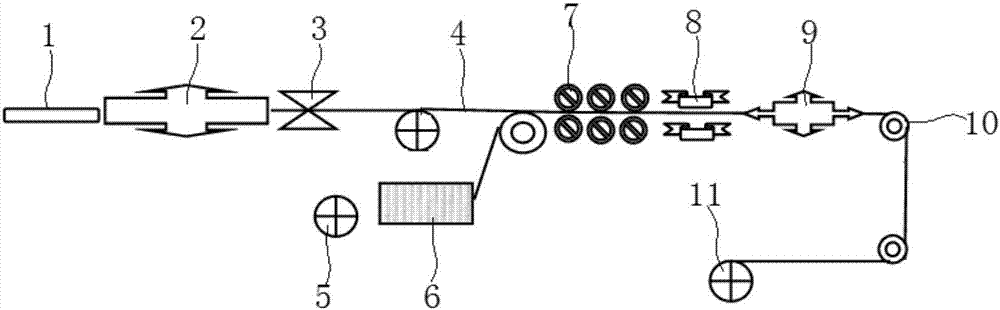

Method used

Image

Examples

Embodiment 1

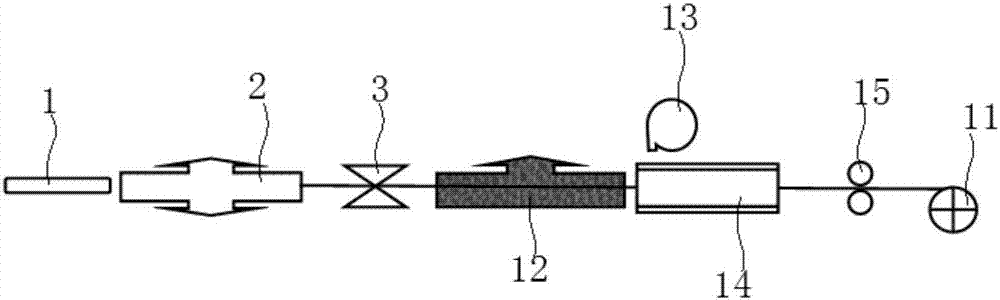

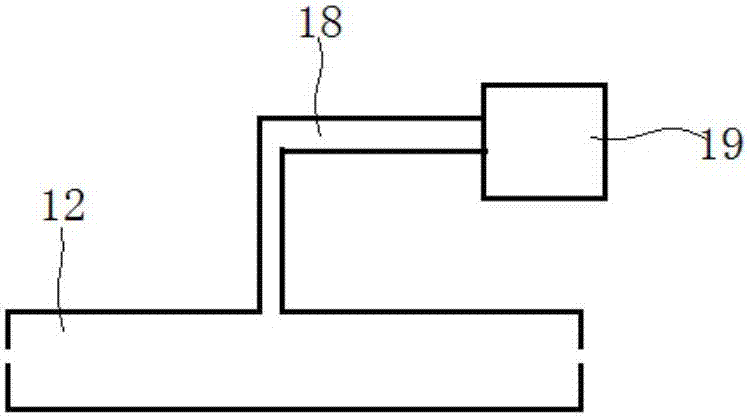

[0052] Such as figure 2 As shown, a production system of a seamless pure calcium cored wire in this embodiment includes a heating device 2, an extruder 3, a vacuum coating treatment tank 12 and a curing processor 14, wherein the heating device 2, the extrusion Machine 3, vacuum coating treatment tank 12 and curing processor 14 are arranged in sequence. Such as image 3 As shown, the above-mentioned vacuum coating treatment tank 12 is connected with the liquid storage device 19 through the liquid inlet pipeline 18, a liquid level gauge is arranged in the said vacuum coating treatment tank 12, and a liquid inlet pump and a control valve are arranged on the liquid inlet pipeline 18 , and the liquid level gauge, liquid inlet pump and control valve are all connected to the control system. The outlet end of the curing processor 14 is also provided with a sizing machine 15 and a rewinder in sequence, and the side of the curing processor 14 is also provided with a hot air device 13...

Embodiment 2

[0062] Such as figure 2 As shown, the production system of a seamless pure calcium cored wire in this embodiment is basically the same in structure as in Embodiment 2, the difference being that the ceramic powder in the nano-ceramic coating filled in the vacuum coating treatment tank 12 is The particle size is 1000 mesh, SiO 2 、 Al 2 o 3 and TiO accounted for 53%, 30%, and 17% of the total weight of the ceramic powder, nano-silica sol, nano-Al 2 o 3 The addition amount of the modified silicone resin and the modified silicone resin are respectively 25%, 10% and 13% of the total weight of the ceramic powder. The additions of absolute ethanol, acetone and polyacrylamide account for 28%, 15% and 0.5% of the total weight (dry weight) of the coating respectively, and the pH value of the coating is 8 and the viscosity is 0.45 Pas.

[0063] The production system of the seamless pure calcium cored wire of this embodiment is used to produce the cored wire, and the specific steps a...

Embodiment 3

[0071] Such as figure 2 As shown, the production system of a seamless pure calcium cored wire in this embodiment is basically the same in structure as in Embodiment 2, the difference being that the ceramic powder in the nano-ceramic coating filled in the vacuum coating treatment tank 12 is The particle size is 800 mesh, SiO 2 、 Al 2 o 3 and TiO accounted for 50%, 30%, and 20% of the total weight of the ceramic powder, respectively, nano-silica sol, nano-Al 2 o 3 The addition amount of the modified silicone resin and the modified silicone resin are respectively 24%, 8% and 11% of the total weight of the ceramic powder. The additions of absolute ethanol, acetone and polyacrylamide account for 27%, 13% and 0.4% of the total weight (dry weight) of the paint respectively, the pH value of the paint is 8, and the viscosity is 0.30Pas.

[0072] The production system of the seamless pure calcium cored wire of this embodiment is used to produce the cored wire, and the specific ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com