Switch for automobile brake lamp

A vehicle braking and switching technology, applied in contact operating parts, contact housings/screens, etc., can solve problems such as contact oxidation, and achieve the effect of improving switch life, meeting the needs of automobile use, and preventing contact oxidation failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

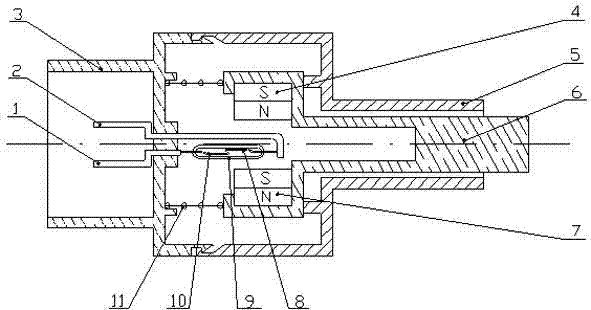

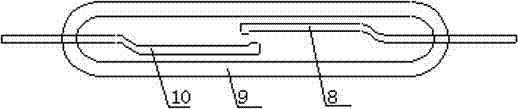

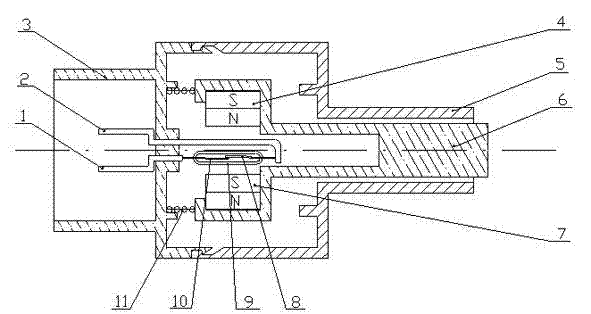

[0020] see figure 1 and figure 2 , the switch for automobile brake lights includes a corresponding matching housing 5 and housing cover 3, a push rod 6, a positive electrode pin 1 and a negative electrode pin 2, and one end of the positive electrode pin 1 and one end of the negative electrode pin 2 are respectively connected with electrodes. The casing 5 is provided with a push rod hole, one end of the push rod 6 extends outside the push rod hole of the casing 5, the other end of the push rod 6 is a U-shaped end, and the two sides of the U-shaped end of the push rod 6 are respectively installed with The upper magnet block 4 and the lower magnet block 7, the two ends of the U-shaped end of the push rod 6 are bent inward respectively, and the bends at both ends are respectively bent and buckled on the end of the magnet block, and the U-shaped end of the push rod 6 is in the middle of the bottom. There are grooves. Both ends of the U-shaped end of the push rod are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com