Lubricant as well as preparation method and application thereof

A lubricant and reaction technology, applied in the field of lubricant and its preparation, can solve the problems of easy oxidation of molybdenum disulfide, etc., and achieve the effects of not being easy to oxidize and fail, solving oxidative decomposition, and good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of lubricant of the present invention comprises the following steps:

[0029] (1) Molybdenum disulfide is added to the piranha solution, stirred continuously for 5-10min, then washed and dried to obtain surface hydroxylated molybdenum disulfide particles;

[0030] (2) The surface hydroxylated molybdenum disulfide particles obtained in step (1) are ultrasonically dispersed in deionized water to form a suspension, then the suspension is mixed with absolute ethanol, and then ethyl orthosilicate, Ammonia water starts to react at a certain temperature, and reacts under electromagnetic stirring for 6 to 24 hours;

[0031] (3) After the reaction in step (2) is over, separate the reaction product of step (2), wash the reaction product with absolute ethanol and deionized water successively, and then carry out vacuum drying to obtain a silica-coated molybdenum disulfide compound material (ie the lubricant of the present invention).

[0032] In the piranha...

Embodiment 1

[0036] The preparation method of present embodiment lubricant comprises the following steps:

[0037] (1) Add 0.003g of molybdenum disulfide powder into the prepared piranha solution, stir continuously for 5min, wash and dry;

[0038] (2) Add 15ml of deionized water to the molybdenum disulfide treated in step (1), ultrasonically disperse for 10 minutes, make a rough suspension, then mix with 30ml of absolute ethanol, add 0.3ml of ethyl orthosilicate, 0.5 ml of ammonia water, start the reaction at 25°C, and react for 16 hours under electromagnetic stirring;

[0039] (3) Separate the above reaction product, wash it twice with absolute ethanol, then wash it twice with deionized water, and then dry it in vacuum to obtain a silicon dioxide-coated molybdenum disulfide composite material (ie, the lubricant of the present invention).

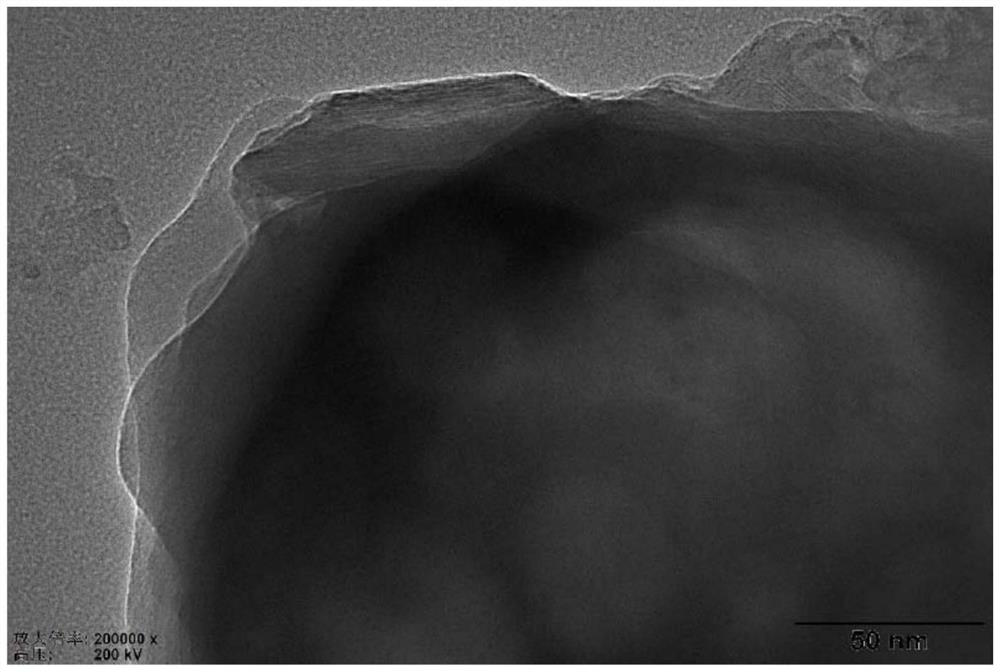

[0040] figure 1 Transmission electron microscope image of the silica-coated molybdenum disulfide composite material prepared in Example 1 of the meth...

Embodiment 2

[0042] The preparation method of present embodiment lubricant comprises the following steps:

[0043] (1) Add 0.003g of molybdenum disulfide powder into the prepared piranha solution, stir continuously for 5min, wash and dry;

[0044](2) Add 10ml of deionized water to the molybdenum disulfide treated in step (1), ultrasonically disperse for 10min, make a rough suspension, then mix with 20ml of absolute ethanol, add 0.8ml of ethyl orthosilicate, 0.6 ml of ammonia water, start the reaction at 25°C, and react for 6 hours under electromagnetic stirring;

[0045] (3) Separate the above reaction product, wash it twice with absolute ethanol, then wash it twice with deionized water, and then dry it in vacuum to obtain a silicon dioxide-coated molybdenum disulfide composite material (ie, the lubricant of the present invention).

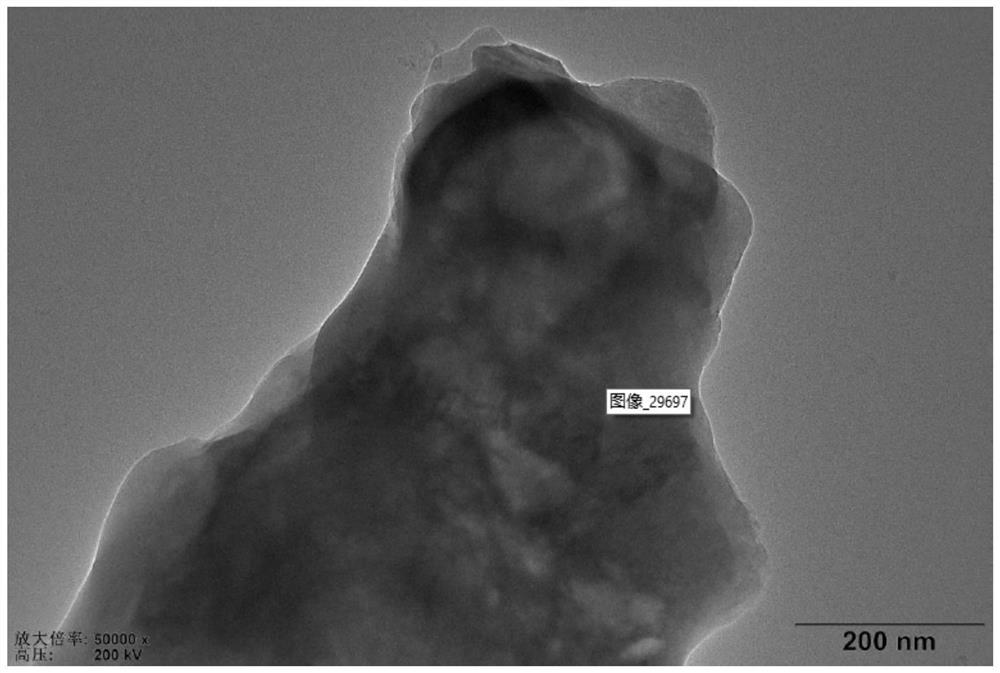

[0046] figure 2 Transmission electron microscope image of the silica-coated molybdenum disulfide composite material prepared in Example 2 of the method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com