A steel-wear-resistant copper alloy layered bearing material, its preparation device and preparation method

A wear-resistant copper and alloy layer technology, applied in the field of alloy material preparation, to achieve the effects of excellent wear resistance, good use effect and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

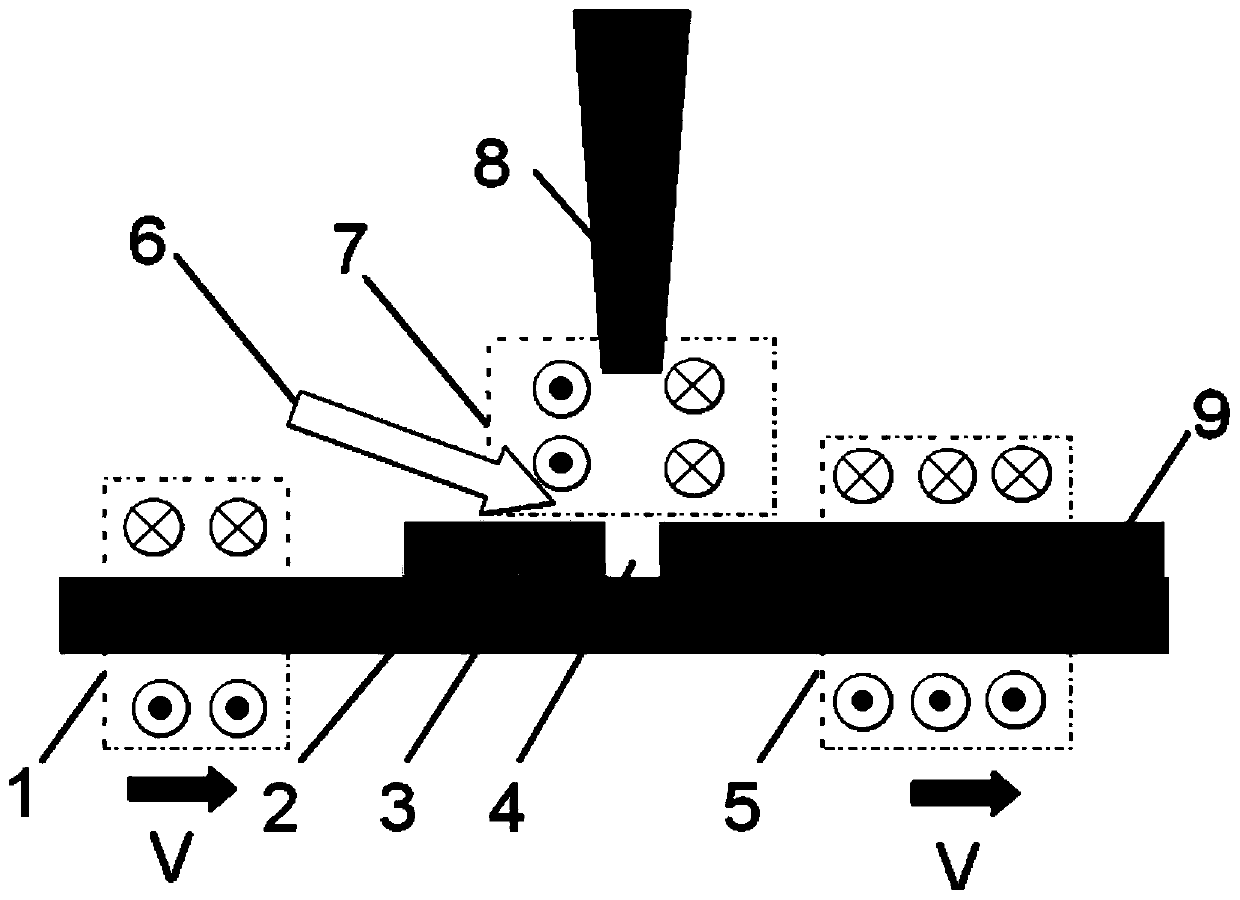

[0038] This embodiment discloses a preparation device for a steel-wear-resistant copper alloy layered bearing material, the structure of which is as follows figure 2 As shown, it includes: substrate transmission channel, high-frequency induction heater coil 1, laser generator 8, pulsed magnetic field generator coil 7 and high-frequency induction normalizing coil 5, and the substrate transmission channel is sequentially arranged on the high-frequency induction heater In the coil and the pulsed magnetic field generator coil, a pulsed magnetic field generator coil is arranged above the substrate transmission channel between the high frequency induction heater coil and the pulsed magnetic field generator coil, and a laser generator is arranged above the pulsed magnetic field generator coil , the laser beam of the laser generator hits the substrate transmission channel below the pulsed magnetic field generator coil, and the wear-resistant copper alloy powder is arranged on the subs...

Embodiment 2

[0050] This embodiment discloses a method for preparing a steel-wear-resistant copper alloy layered bearing material, using the preparation device for the steel-wear-resistant copper alloy layered bearing material described in Example 1.

[0051] The preparation method of the carbon alloy steel-wear-resistant copper alloy layered bearing material comprises the following steps:

[0052] 1) A carbon alloy steel plate with a thickness of 3 mm and a width of 100 mm is used as the carbon alloy steel substrate, and NaOH and HCl are used to clean the oxide and oil stains on the surface of the carbon alloy steel substrate.

[0053] 2) A wear-resistant copper alloy melt with uniform composition is smelted by electromagnetic stirring. The composition is 24wt.% Pb and 2wt.% Sn, and the rest is Cu. When the melt temperature reaches 1200 ° C, blow high-purity argon into it Atomized into powder to prepare wear-resistant copper alloy powder 3.

[0054] 3) Cover the 1.5mm thick wear-resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com