Manufacturing technology of unmanned aerial vehicle and high-strength unmanned aerial vehicle manufactured through manufacturing technology

A drone and mechanism technology, applied in wings, aircraft parts, household components, etc., can solve problems such as inability to perform mechanical processing, and achieve the effect of improving impact resistance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

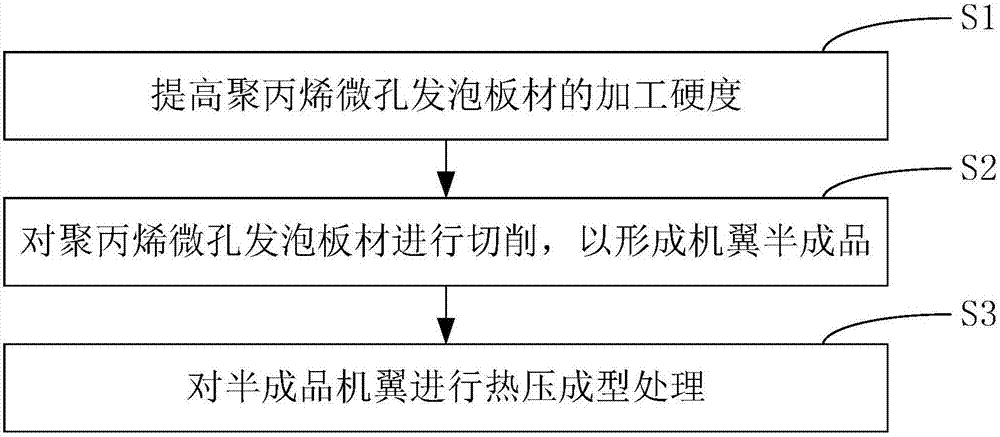

Image

Examples

Embodiment 1

[0026] This embodiment provides a manufacturing process for drones, that is, using polypropylene microporous foam plates as raw materials to prepare drone accessories.

[0027] Wherein, the UAV accessories include but not limited to wings, fuselage, empennage and so on.

[0028] For polypropylene microporous foam sheet, although microporous brings the above-mentioned advantages, it also brings the problem of difficult machining, that is, due to microporous, polypropylene microporous foam sheet is light in texture and has certain toughness. , but it is not conducive to the preparation of corresponding accessories by mechanical processing.

[0029] Therefore, aiming at the technical problem of difficult mechanical processing of polypropylene microcellular foamed sheet, the first step of the present invention is to make the polypropylene microcellular foamed sheet meet the processing hardness required for mechanical processing, and then perform mechanical processing by CNC numeri...

Embodiment 2

[0051] On the basis of Embodiment 1, Embodiment 2 provides an unmanned aerial vehicle.

[0052] The UAV includes a wing made of polypropylene microporous foam sheet; and the wing is prepared by the UAV preparation process described in Example 1.

[0053]After the wing is made of polypropylene microcellular foamed sheet, it has the advantages of lightness and toughness made of polypropylene microcellular foamed sheet, and makes the wing resistant to stretching, compression, torsion, impact, etc. Capabilities are increased, extending the lifespan of the drone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com