Damping energy dissipation type debris flow grid dam and construction method thereof

A technology for debris flow and grid dam, applied in the field of damping energy-consuming debris flow grid dam and its construction, can solve the problems of large cross-sectional size of structural members, limited construction site, difficult material transportation, etc., to improve impact resistance, The effect of optimized impact resistance and safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are part of the embodiments of the present application, not all of them. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the scope of protection of this application.

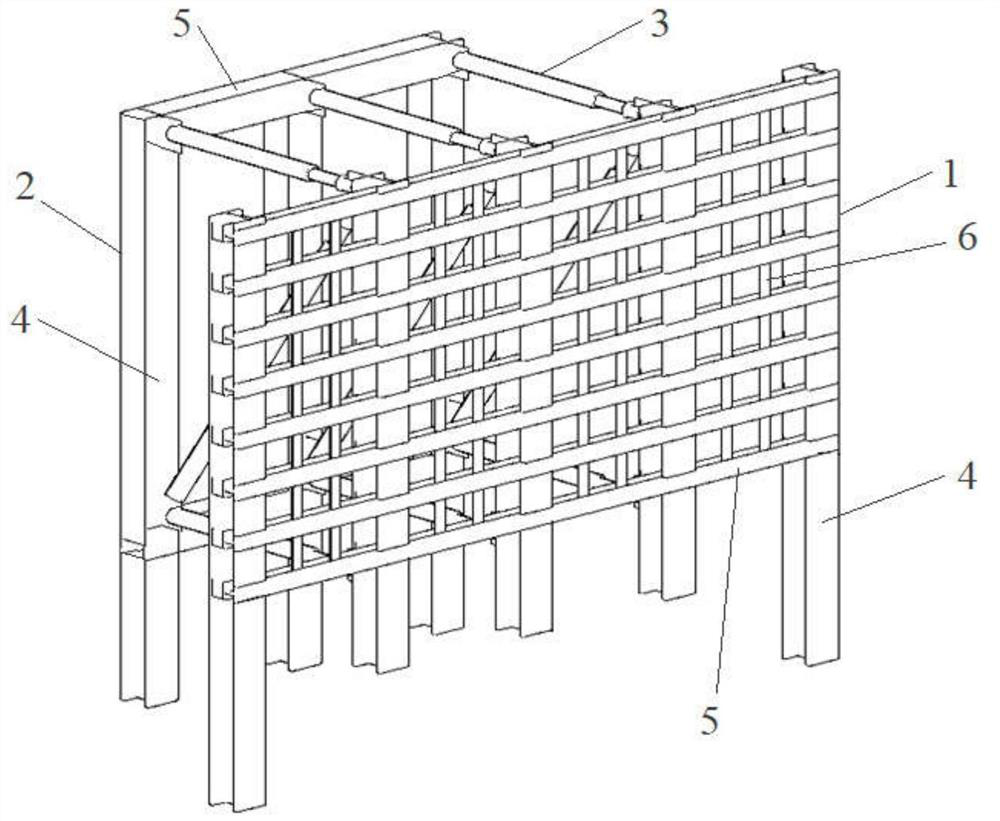

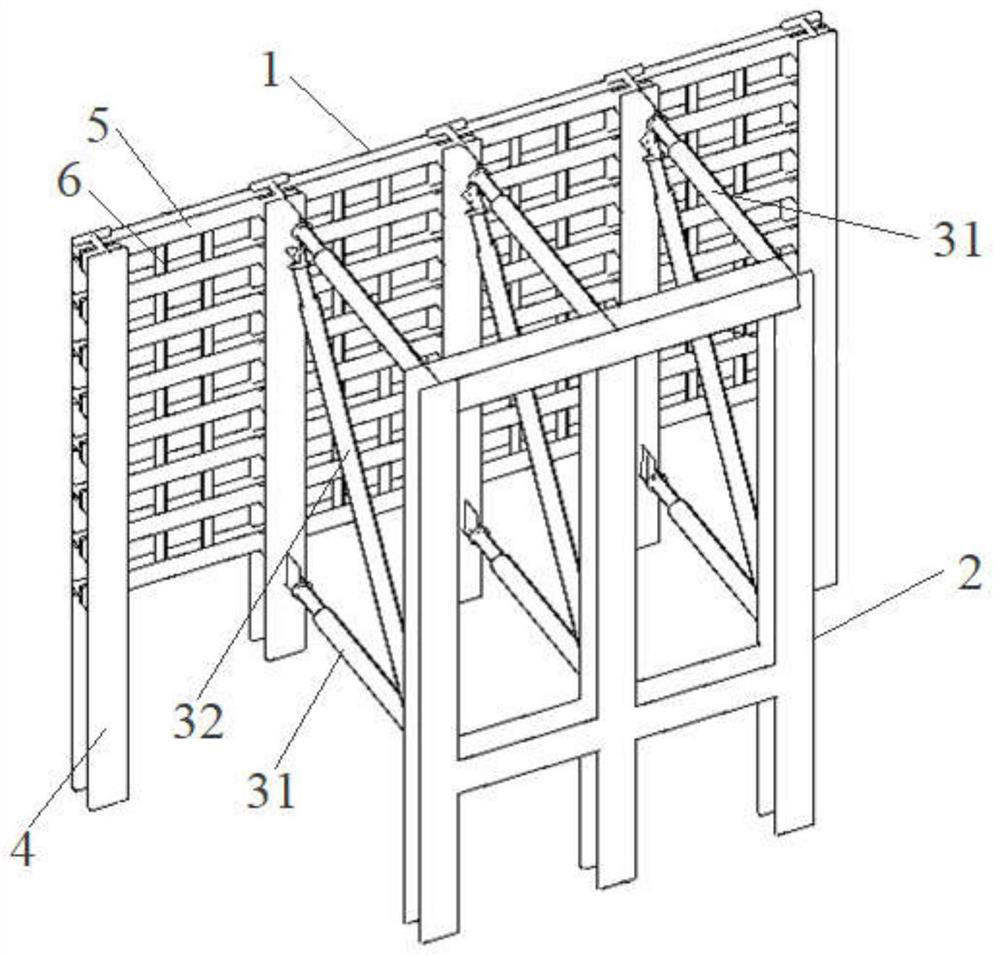

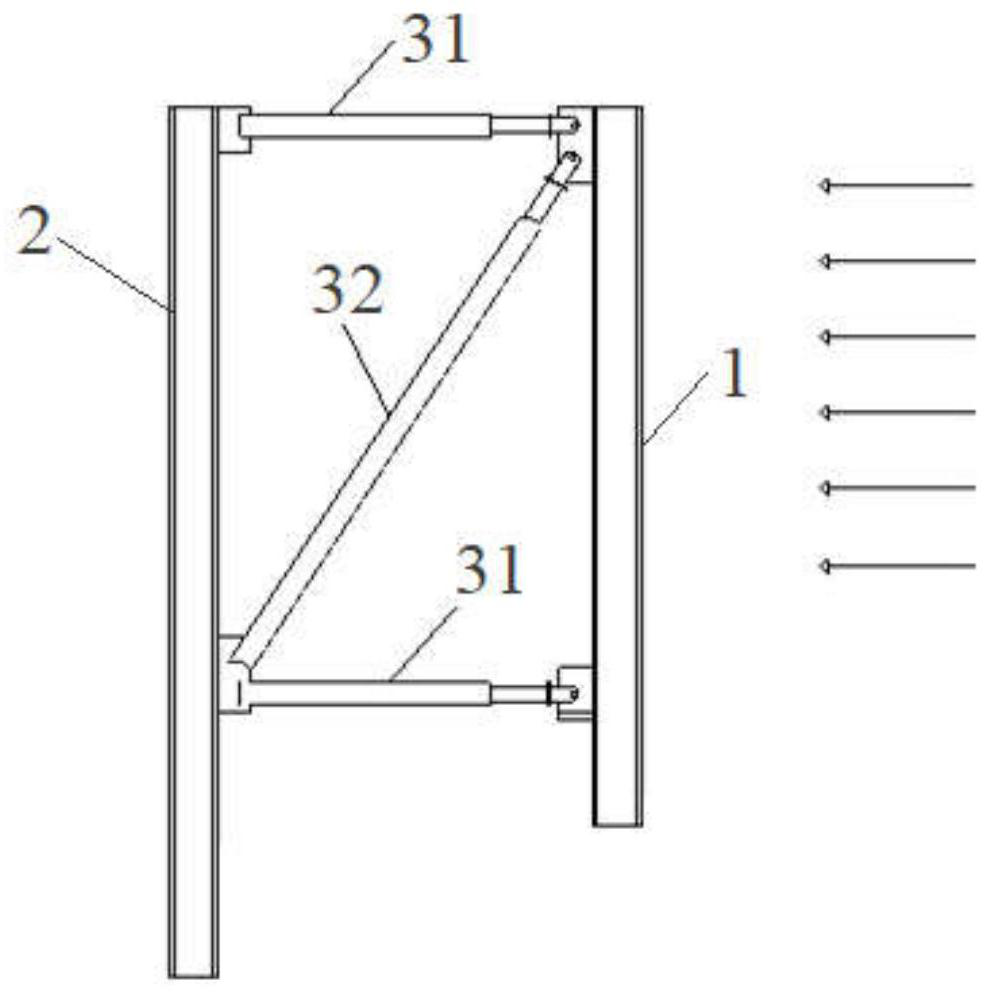

[0031] The embodiment of the present invention aims at the energy consumption of the structure itself when the traditional retaining dam resists the impact force of debris flow, and the method of enhancing the strength, stiffness and ductility of the structure itself is required to ensure its safety, which causes many defects, so a damping energy-dissipating debris flow grid is provided Barrier dams are used in the prevention and control of debris flows. Of course, the embodiments of the present invention can also be applied to hydrolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com