Flame-retardant lightweight construction panel and method for manufacturing same

A manufacturing method and technology for construction, applied in the direction of building structure, construction, building components, etc., can solve the problems of casualties, property losses, refractory waste, etc., to improve impact resistance, improve impact strength, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] 65 parts by weight of waste gypsum, 55 parts by weight of feldspar, 45 parts by weight of Vermiculite was mixed to prepare a mortar for molding.

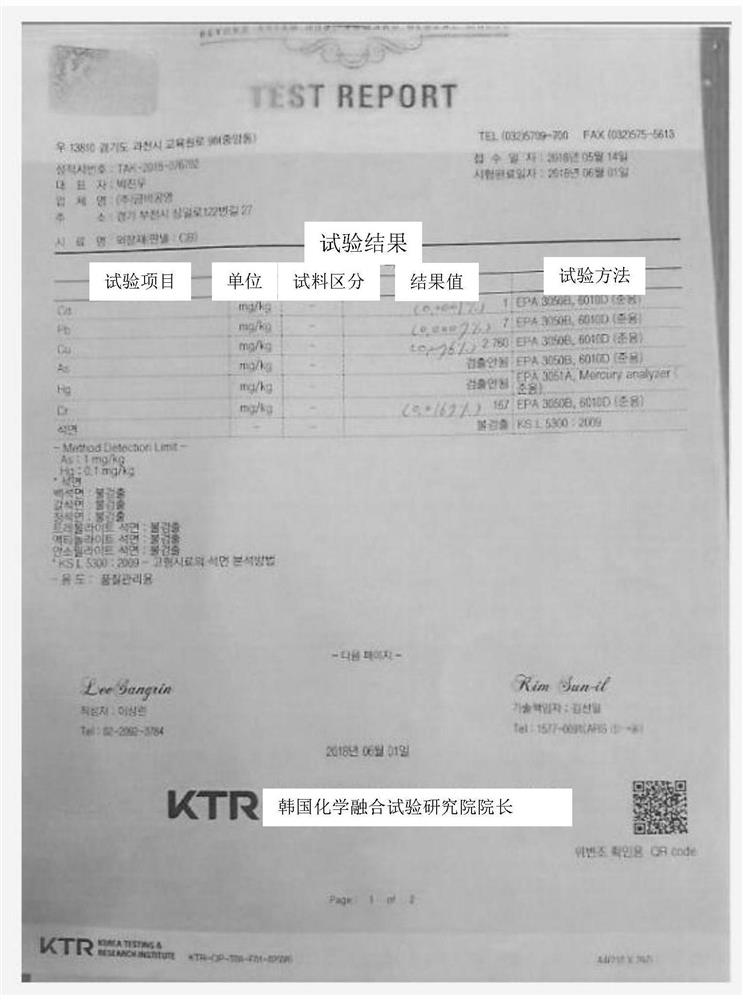

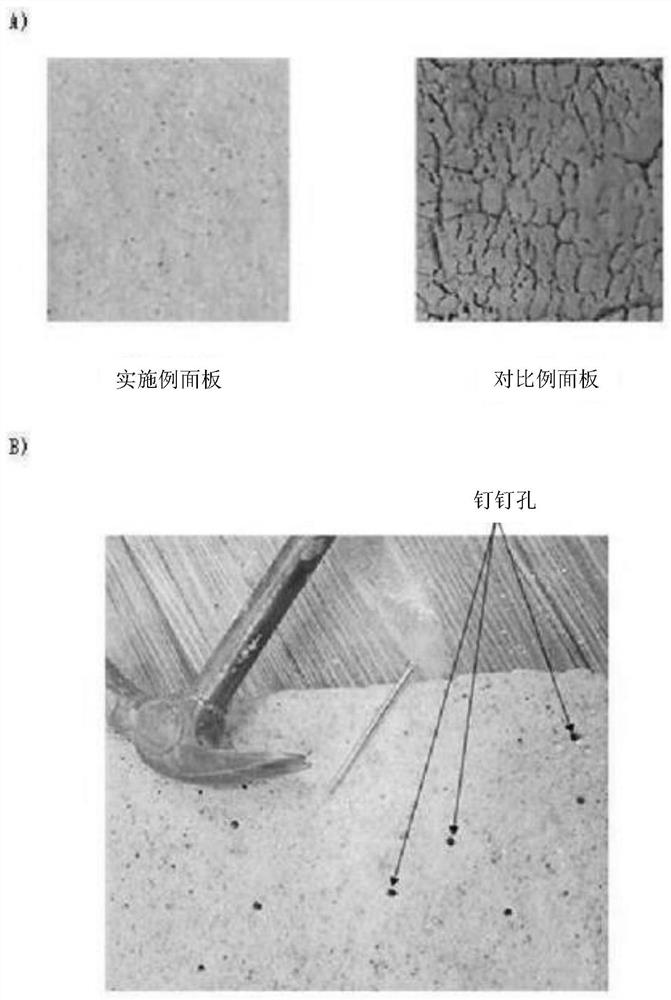

[0037] After molding the molding mortar into a plate-like molding by using a mold, a surface treatment agent is used to coat the surface of the molding with a thickness of about 1 to 2 mm. The surface treatment agent is composed of pigments and mica in the same weight ratio. Powder, vermiculite powder and garnet powder, then dried, put it into electric furnace, make it burn at 1350 ℃ for about one hour, and then cool it at normal temperature. Through the above process, the Lightweight panels for flame-retardant construction, and then commissioned a test analysis for the heavy metal content of the panels manufactured, figure 1 As a result (test report card).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com