Electric vehicle battery box housing having heat dissipation and water exhaust structure

A technology of electric vehicle battery and drainage structure, which is applied in the direction of secondary battery, structural parts, battery pack parts, etc., and can solve the problems of losing the weight of the battery box, reducing the volume and reducing the number of batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

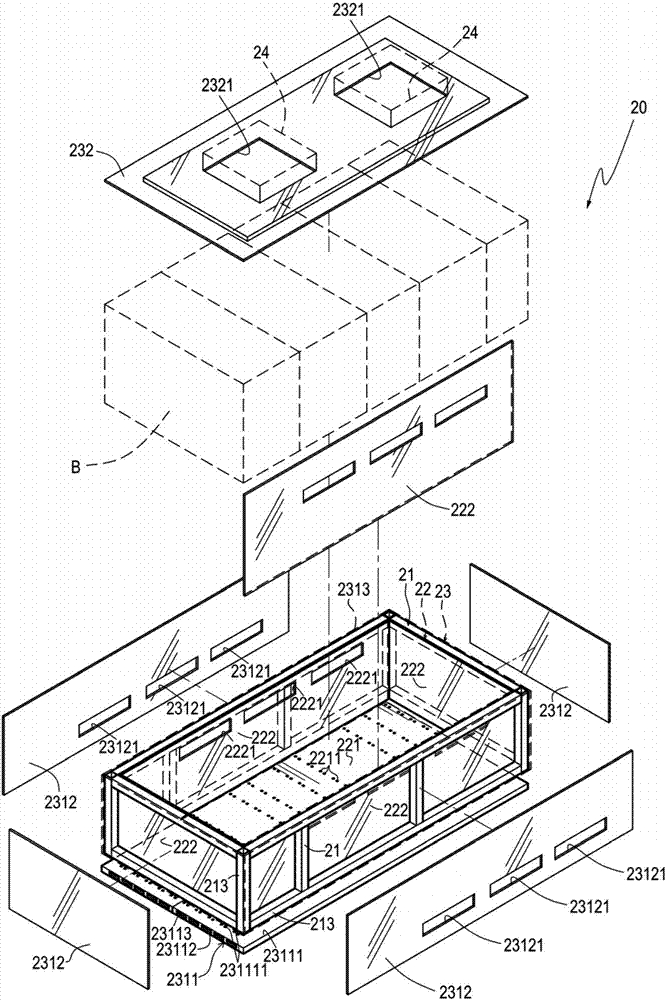

[0062] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

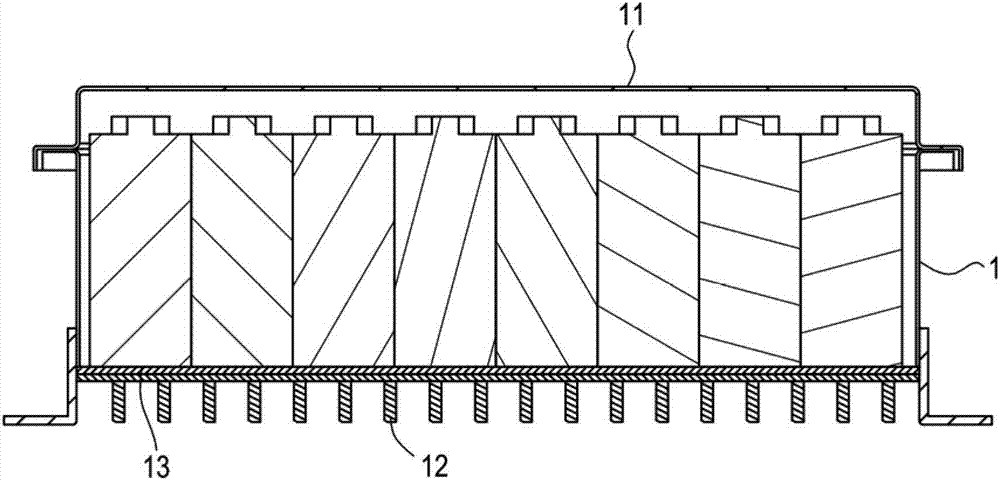

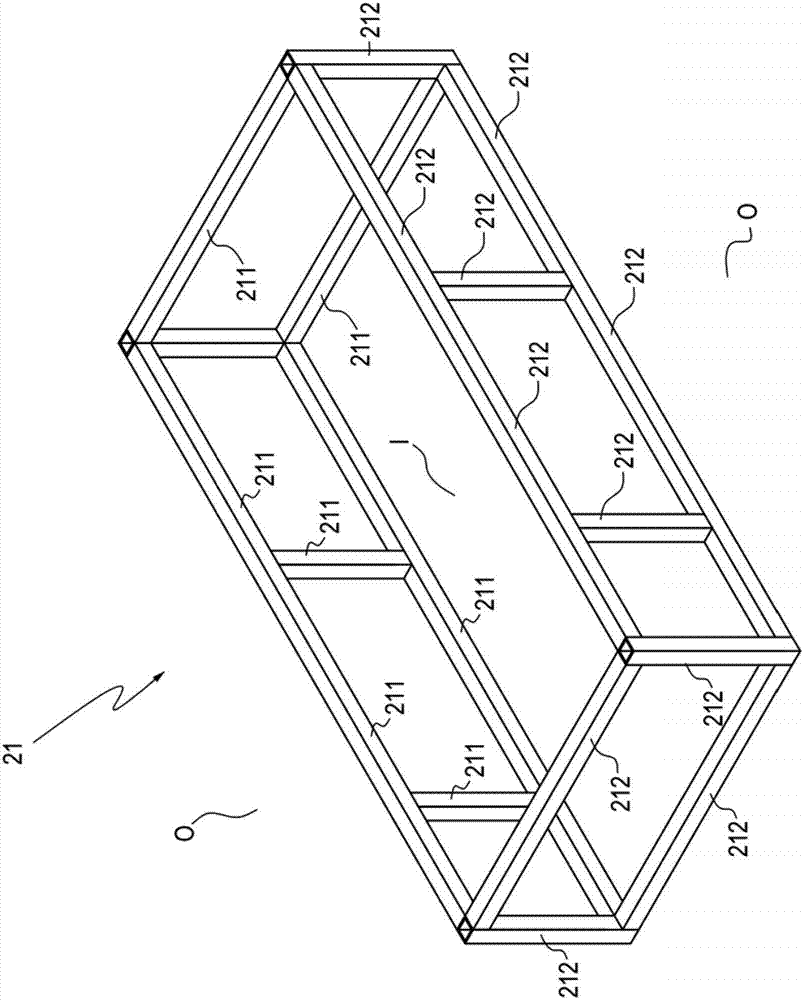

[0063] Please refer to Figure 2 ~ Figure 4 shown. The electric vehicle battery case housing with heat dissipation and drainage structure in this embodiment is mainly suitable for accommodating a battery module B. The electric vehicle battery case housing 20 includes a frame 21, an inner box body 22 and an outer box Body 23: The frame 21 has an inner surface 211 facing the inner I of the frame 21 and an outer surface 212 facing the outer O of the frame 21. In one embodiment, the frame 21 is made of a plurality of extruded aluminum The bracket 213 is assembled; the inner box body 22 includes an inner bottom plate 221 joined to the bottom surface of the inner surface 211 and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com