An environment-friendly two-component intermediate paint for vehicles

An environmentally friendly, two-component technology, used in coatings, anti-corrosion coatings, etc., can solve problems such as high VOC emissions and inability to meet environmental protection requirements, and achieve good hiding power, reduced construction VOC, and good sandability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

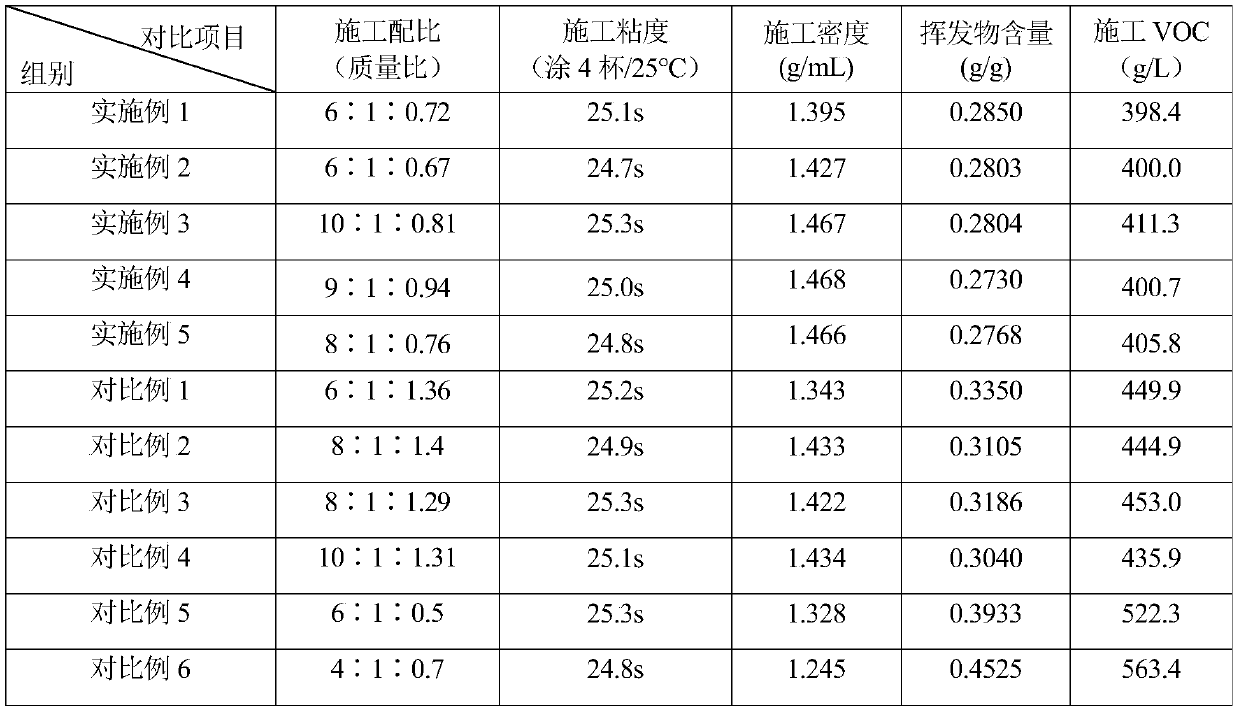

Examples

Embodiment 1

[0046]An environment-friendly two-component intermediate paint for vehicles, which is composed of a main paint, a curing agent and a diluent, and the main paint is composed of the following components in parts by weight: 32 parts of hydroxyl acrylic resin, 2 parts of hydroxyl polyester resin, 3 parts of epoxy resin, 0.7 parts of wetting and dispersing agent, 0.4 parts of leveling agent, 21 parts of titanium dioxide, 16 parts of talc powder, 6.5 parts of 2500 mesh precipitated barium sulfate, 8 parts of zinc phosphate, 0.5 parts of anti-settling thixotropic agent, 0.05 parts of catalyst, 10 parts of solvent, wherein the solvent includes: 4 parts of butyl acetate, 4 parts of PMA, 2 parts of trimethylbenzene, the curing agent is a mixture of 80 parts of HDI trimer polyisocyanate curing agent and 20 parts of butyl acetate, diluted Agents include: 25 parts of butyl acetate, 50 parts of xylene, 5 parts of DBE, and 20 parts of PMA.

[0047] Wherein, the hydroxyl value of the hydroxy ...

Embodiment 2

[0057] In the present embodiment, an environment-friendly two-component intermediate paint for vehicles is composed of main paint, curing agent and diluent, and the main paint is composed of the following components in parts by weight: 35 parts of hydroxyl acrylic resin, hydroxyl polyester 1 part of resin, 1 part of epoxy resin, 0.3 parts of wetting and dispersing agent, 0.7 parts of leveling agent, 30 parts of titanium dioxide, 12 parts of talc powder, 7 parts of 2500 mesh precipitated barium sulfate, 4 parts of zinc phosphate, anti-settling thixotropy 0.4 parts of agent, 0.05 parts of catalyst, solvents include: 4 parts of butyl acetate, 4 parts of PMA, 2 parts of trimethylbenzene, take 9 parts of the mixture, curing agent is 75 parts of HDI trimer polyisocyanate curing agent, butyl acetate 25 parts of the mixture, diluents include: 25 parts of butyl acetate, 50 parts of xylene, 5 parts of DBE, 20 parts of PMA.

[0058] Wherein, the hydroxyl value of the hydroxy acrylic resi...

Embodiment 3

[0061] In the present embodiment, an environment-friendly two-component intermediate paint for vehicles is composed of main paint, curing agent and diluent, and the main paint is composed of the following components in parts by weight: 30 parts of hydroxyl acrylic resin, hydroxyl polyester 1 part of resin, 2 parts of epoxy resin, 0.5 part of wetting and dispersing agent, 0.5 part of leveling agent, 25 parts of titanium dioxide, 15 parts of talc powder, 8 parts of 2500 mesh precipitated barium sulfate, 6 parts of zinc phosphate, anti-settling thixotropy 0.3 parts of agent, 0.04 parts of catalyst, solvent includes: 8 parts of butyl acetate, 8 parts of PMA, 4 parts of trimethylbenzene, take 12 parts in the mixture, curing agent is 78 parts of HDI trimer polyisocyanate curing agent, butyl acetate A mixture of 22 parts, diluents include: 25 parts of butyl acetate, 50 parts of xylene, 5 parts of DBE, 20 parts of PMA.

[0062] Wherein, the hydroxyl value of the hydroxy acrylic resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com