Novel water-based waterproof and heat-insulating decorative coating and its preparation technology thereof

A decorative, water-based technology, applied in reflective/signal paints, coatings, etc., can solve the problems of fading, poor waterproof and heat insulation effect, etc., and achieve the effect of tensile strength clothing and high weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

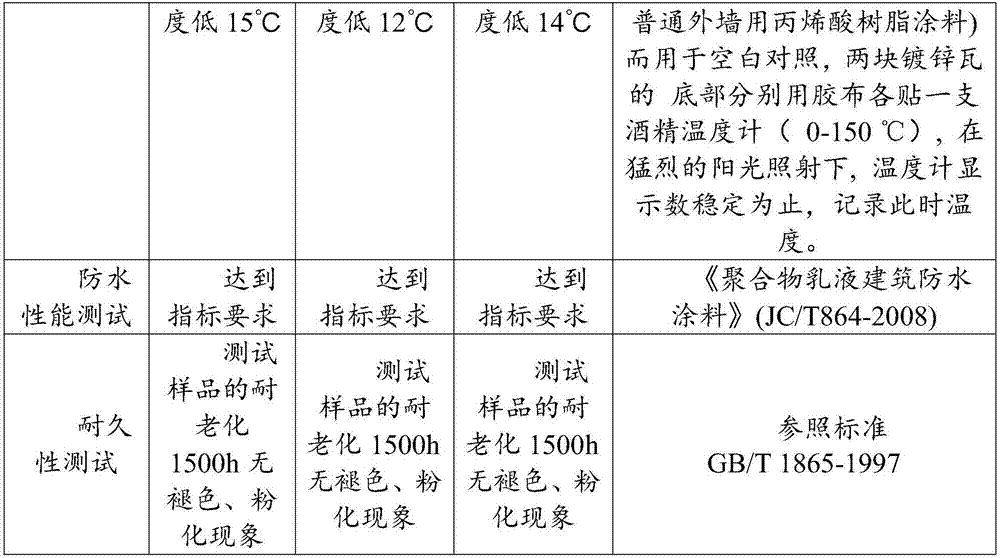

Examples

Embodiment 1

[0025] A novel water-based waterproof heat-insulating decorative coating preparation process, specifically according to the following steps:

[0026] 1) Preparation of water-based color paste

[0027] a, preparation of yellow Ti-Y-Mo nano pigment

[0028] Grind and mix 30kg of titanium dioxide, 12kg of yttrium oxide and 5kg of molybdenum oxide in an ethanol medium with a ball mill for 1 hour, place the precursor powder in a muffle furnace, heat it at 1000°C for 3 hours and calcine it, then cool with the furnace , to obtain yellow Ti-Y-Mo nano-pigment, infrared reflectivity 91-94%, average particle size 180nm;

[0029] b. Add 43kg of deionized water into the dispersing tank of the high-speed disperser, start the disperser, adjust the speed to 1100r / min, add 1kg of defoamer, 2kg of wetting agent, 9kg of dispersant, 3kg of thickener, and rotate at a speed of Raise it to 1400r / min, disperse for 8min; reduce the speed to 1100r / min, slowly add 40kg of yellow Ti-Y-Mo nano pigment t...

Embodiment 2

[0033] 1) Preparation of water-based color paste

[0034] a, preparation of red Ti-Fe-Cr nano pigment

[0035] Grind and mix 30kg of titanium dioxide, 7.5kg of iron oxide and 0.5kg of chromium oxide in an ethanol medium with a ball mill for 1 hour, place the precursor powder in a muffle furnace, heat it at 1000°C for 3 hours for calcination, and cool with the furnace , that is, red Ti-Fe-Cr nano pigments are obtained, the infrared reflectivity is 92-95%, and the average particle size is 165nm;

[0036] b, preparation of green Ti-Zn-Co nano pigments

[0037] Grinding and mixing 25kg of titanium dioxide, 1kg of zinc oxide and 1kg of cobalt oxide in an ethanol medium with a ball mill for 1 hour, placing the precursor powder in a muffle furnace, and calcining at 1000°C for 3 hours, then cooling with the furnace, that is Obtain green Ti-Zn-Co nano-pigments with an infrared reflectance of 90-94% and an average particle size of 190nm;

[0038]c. Add 44kg of deionized water into th...

Embodiment 3

[0042] 1) Preparation of water-based color paste

[0043] a, preparation of red Ti-Fe-Cr nano pigment

[0044] Grind and mix 30kg of titanium dioxide, 7.5kg of iron oxide and 0.5kg of chromium oxide in an ethanol medium with a ball mill for 1 hour, place the precursor powder in a muffle furnace, heat it at 1000°C for 3 hours for calcination, and cool with the furnace , that is, red Ti-Fe-Cr nano pigments are obtained, the infrared reflectivity is 92-95%, and the average particle size is 165nm;

[0045] b, preparation of purple Ti-Mn-Nd nano-pigments

[0046] 30kg of titanium dioxide, 8.0kg of manganese chloride and 0.4kg of neodymium oxide were ground and mixed in an ethanol medium by a ball mill for 1 hour. After cooling, the red Ti-Fe-Cr nano-pigment is obtained, the infrared reflectivity is 92-96%, and the average particle size is 175nm;

[0047] c. Add 45kg of deionized water into the dispersing tank of the high-speed disperser, start the disperser, adjust the speed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com