A kind of high temperature resistant aramid fiber lithium ion battery composite diaphragm and preparation method thereof

A lithium-ion battery and composite separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as small interface stress, and achieve the effects of small interface stress, mild reaction, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

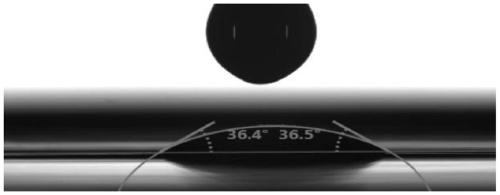

[0034] A preparation method of a high temperature resistant aramid fiber lithium ion battery composite diaphragm of the present invention includes the following steps: (1) preparation of aramid fiber casting solution: mixing aramid fiber, pore-forming agent, inorganic ceramic particles and organic solvent, At 50-80°C, stir to completely dissolve the aramid fiber and the pore-forming agent to obtain a casting solution; (2) Degassing: defoaming the casting solution obtained in step (1) at 50-80°C for 5-60min , until there are no bubbles; (3) Non-solvent-induced phase inversion method film formation: take the base film, apply a layer of deaerated casting liquid on the base film, stay for 5-60s, and place it in a solidification bath for solidification. The coagulation bath is a solvent and non-solvent coagulation bath or a steam coagulation bath. After coagulation for 1-10 minutes, take the base film with aramid fiber, soak it in water or overflow with tap water for 10-60 minutes, ...

Embodiment 1

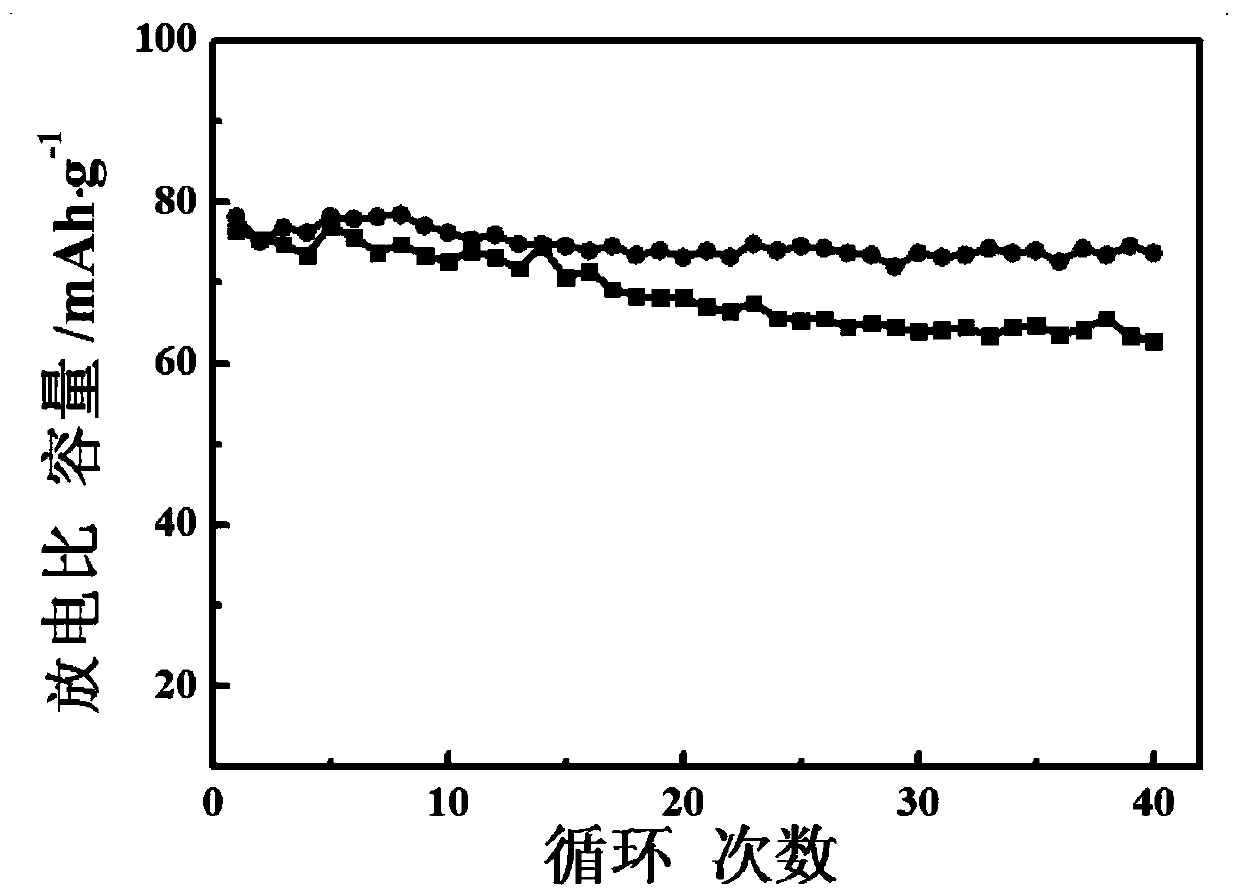

[0038] Mix 5g of aramid fiber, 1.25g of glycerin, 1.25g of polyvinylpyrrolidone, 0.25g of alumina particles (average particle size of 10nm), and 42.25g of DMAc, where the aramid fiber is taken from the aramid fiber polymer, wherein the aromatic fiber in the aramid fiber polymer is aromatic. The solid content of the fiber is 10%, and mechanical stirring is carried out in an oil bath at 50 ° C until the aramid fiber and the pore-forming agent are completely dissolved, and the casting liquid of the aramid fiber is obtained; after stopping the stirring, in the 50 ° C oil bath, defoaming 5min; flatly lay a 20 μm PE base film on a clean glass plate, the porosity of the PE base film is 30%, pour an appropriate amount of defoamed casting liquid on the PE base film, scrape the film with a wire rod, After staying in the air for 5s, slowly and uniformly immersed in a coagulation bath of DMAc and water at room temperature to form a film. After 1min, peel off the PE film with aramid, soak i...

Embodiment 2

[0041] Mix 4.54g of aramid fiber, 1g of acetone, 1.5g of polyvinylpyrrolidone, 0.5g of silica particles (average particle size of 30nm), and 42.46g of DMF, where the aramid fiber is taken from the aramid fiber polymer, which is in the aramid fiber polymer. The solid content of the aramid fiber is 22%, the aramid fiber is para-aramid fiber, and the molecular weight of the aramid fiber is 5000-10000Da. Mechanical stirring is performed in an oil bath at 60 ° C until the aramid fiber and the pore-forming agent are completely dissolved, and the aramid fiber is obtained. After stopping stirring, defoaming in an oil bath at 60°C for 10min; flatly lay a 20μm PE base film on a clean glass plate, the PE base film has a porosity of 30%, using dip-coated After 3 minutes, peel off the PE film with aramid fiber, soak it in water for 20 minutes, and then take it out; at 60 ℃ oven, after drying for 45min, take out.

[0042] The lithium-ion battery composite separator in this embodiment is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com