Magnesium-copper coating for bone implant and preparation method thereof

A technology of copper coating and bone implantation, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of bone compatibility infection of implant materials, achieve good biocompatibility, Effect of reducing infection and increasing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

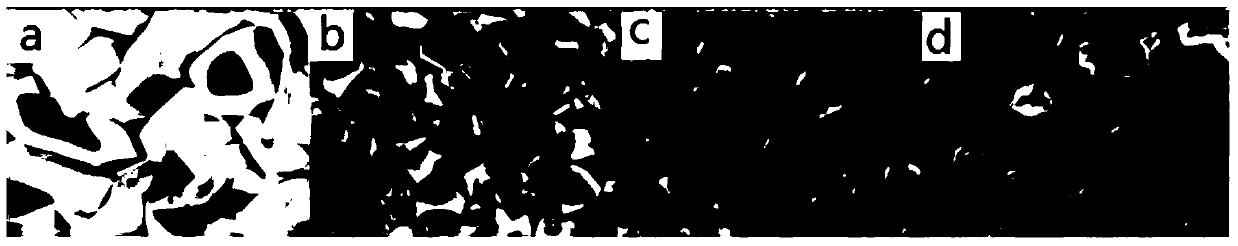

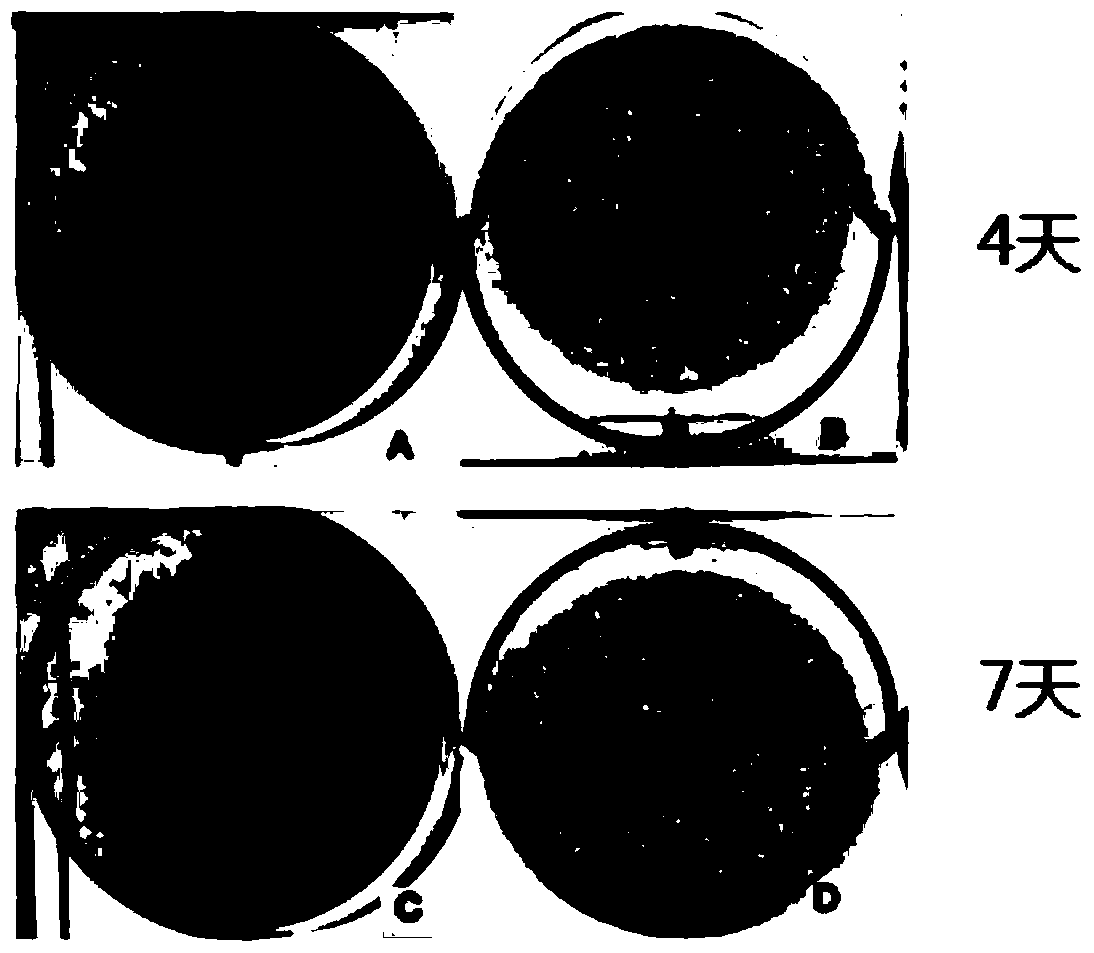

[0031] Put the porous titanium alloy (Ti-6Al-4V) sample into the furnace body 1 of the deposition chamber; put the copper chloride powder into the furnace body 2 of the evaporation chamber, and put pure magnesium into the high temperature zone of the furnace body 1 of the deposition chamber, and the atomic ratio is Magnesium: copper chloride = 25:1, then connect the air circuit, check the sealing condition, and draw a limit vacuum (10 -4 Pa), the whole system was repeatedly purged 3 times with argon to ensure that the oxygen content was minimized. Set the deposition temperature to 300°C, the copper chloride source evaporation temperature to 200°C, the working vacuum to 5Pa, the hydrogen flow to 50SCCM, the deposition time to 3h, the thickness of the deposited metal magnesium-copper layer to be 200μm, and the mass percentage of copper to be 2%. To determine the cytocompatibility of the coating, ALP staining was performed and the results were as follows image 3 As shown, after...

Embodiment 2

[0033] Put the porous titanium alloy (Ti-6Al-4V) sample into the furnace body 1 of the deposition chamber; put the copper chloride powder into the furnace body 2 of the evaporation chamber, and put pure magnesium into the high temperature zone of the furnace body 1 of the deposition chamber, and the atomic ratio is Magnesium: copper chloride = 20:1, then connect the air circuit, check the sealing condition, and draw a limit vacuum (10 -4 Pa), the whole system was repeatedly purged 3 times with argon to ensure that the oxygen content was minimized. Set the deposition temperature to 200°C, the copper chloride source evaporation temperature to 300°C, the working vacuum to 5Pa, the hydrogen flow rate to 100SCCM, the deposition time to 2h, the thickness of the deposited metal magnesium-copper layer to be 100μm, and the mass percentage of copper to be 5%. X-ray diffraction pattern as Figure 4 As shown, due to the relatively low copper content, only the diffraction information of m...

Embodiment 3

[0035] Put the porous titanium alloy (Ti-6Al-4V) sample into the furnace body 1 of the deposition chamber; put the copper chloride powder into the furnace body 2 of the evaporation chamber, and put pure magnesium into the high temperature zone of the furnace body 1 of the deposition chamber, and the atomic ratio is Magnesium: copper chloride = 15:1, then connect the air circuit, check the sealing condition, and draw a limit vacuum (10 -4Pa), the whole system was repeatedly purged 3 times with argon to ensure that the oxygen content was minimized. Set the deposition temperature to 150°C, the evaporation temperature of the copper chloride source to 300°C, the working vacuum to 50Pa, the flow rate of hydrogen to 100SCCM, the deposition time to 1.5h, the thickness of the deposited metal magnesium-copper layer to be 150μm, and the mass percentage of copper to be 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com