Solar cell diffusion method and solar cell obtained thereby

A technology of solar cells and diffusion methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as increasing recombination and reducing efficiency, and achieves the effects of avoiding heavy doping, increasing built-in electric fields, and avoiding interstitial atoms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] A solar battery sheet, prepared by the following method:

[0049] Step 1: Getting Started

[0050] Prepare the process, set the temperature in the furnace to 760-790°C, and control the nitrogen flow rate at 10,000-30,000 sccm;

[0051] Step 2: Enter the boat

[0052] The time is controlled at 600-800s, the temperature in the furnace is set at 760-790°C, and the flow rate of continuous nitrogen gas is controlled at 10000-30000sccm;

[0053] Step 3: Heat Up

[0054] The time is controlled at 600-800s, the temperature in the furnace is stabilized at 760-790°C, the flow rate of continuous nitrogen gas is controlled at 10000-30000sccm, and the pressure in the furnace is controlled at 50-200mba;

[0055] Step 4: Low Temperature Diffusion

[0056] The time is controlled at 600-900s, the temperature in the furnace is at 760-790°C, the continuous flow of nitrogen is controlled at 10000-30000sccm, the flow of oxygen is controlled at 1000-2000sccm, and the flow of nitrogen car...

Embodiment 1

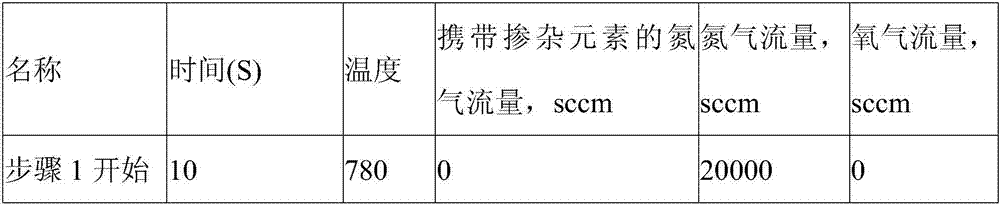

[0083] The specific conditions of embodiment 1 are shown in table 1:

[0084] The processing condition of table 1 embodiment 1

[0085]

[0086]

[0087] In Table 1, n is an integer greater than or equal to 0.

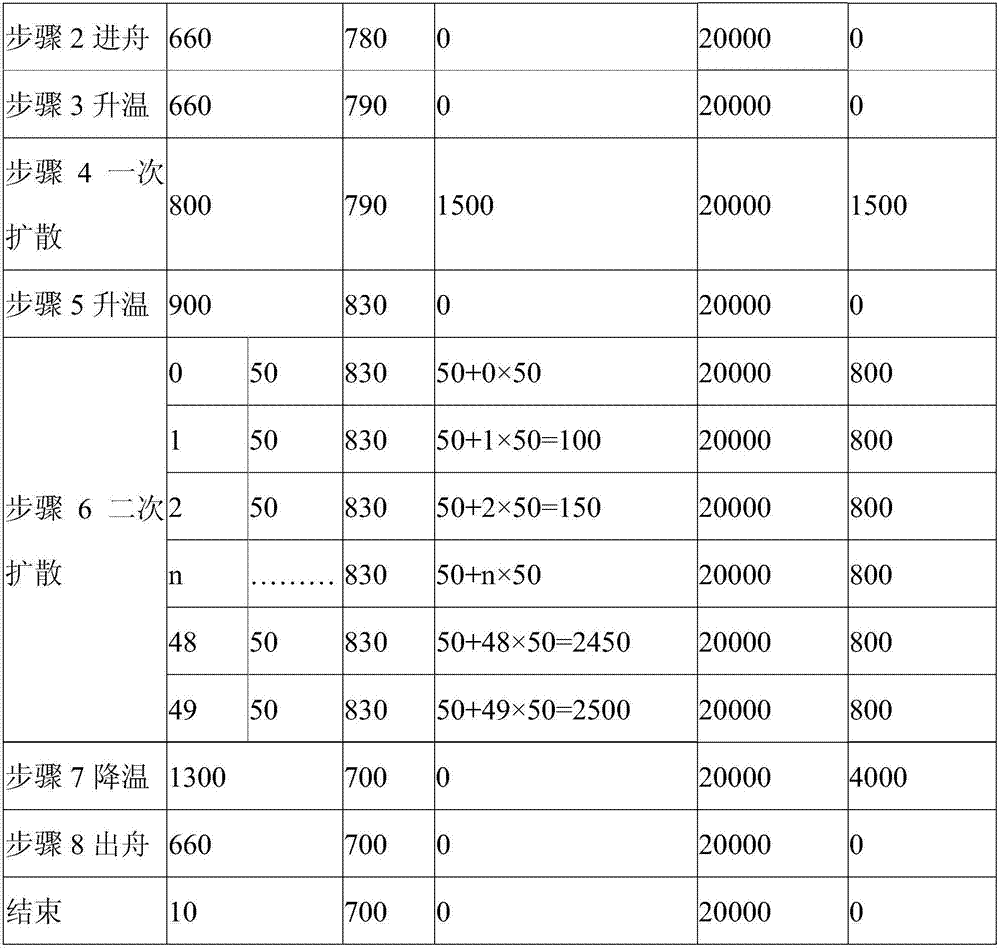

[0088] The specific conditions of Comparative Example 1 are shown in Table 1:

[0089] The technological condition of table 1 comparative example 1

[0090]

[0091]

Embodiment 2

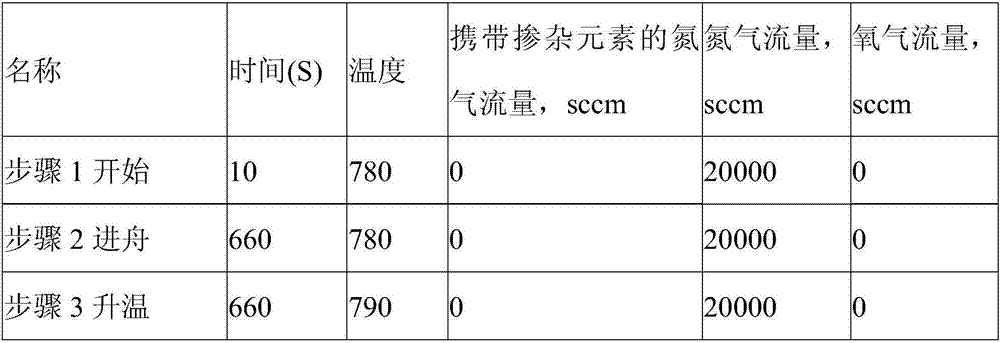

[0092] The specific conditions of embodiment 2 are shown in Table 1:

[0093] The process condition of table 2 embodiment 2

[0094]

[0095]

[0096] In Table 1, n is an integer greater than or equal to 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com