Odorant for fuel gases for anion membrane fuel cells, fuel gas and power generation system using anion membrane fuel cell

A fuel gas and fuel cell technology, applied in fuel cell additives, fuel cells, solid electrolyte fuel cells, etc., can solve problems such as practical obstacles, air pollution, oxidation catalyst poisoning, etc., and achieve the effect of significant effect and low threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

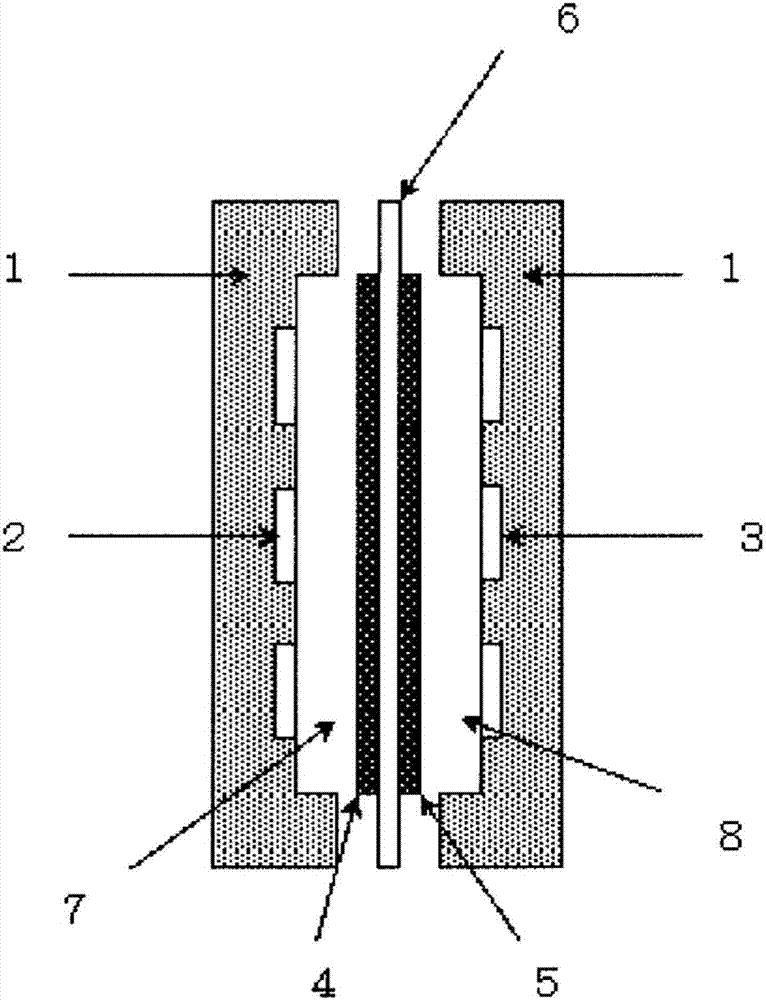

Image

Examples

Embodiment 1~10

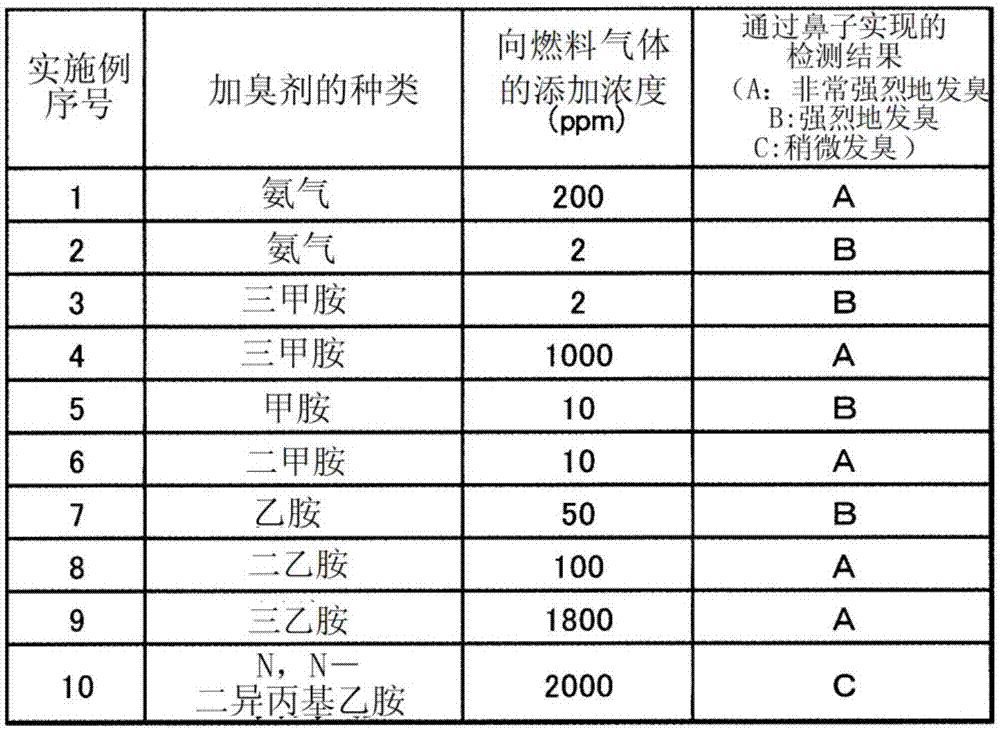

[0062]Various concentrations of the odorant of the present invention shown in Table 1 were added to hydrogen as fuel gas. These odorant-added fuel gases were released into the atmosphere at 1 ml / min. The effectiveness as an odorant was confirmed by detecting the presence or absence of the odor with the nose from above 50 cm.

[0063] [Table 1]

[0064] Table 1

[0065]

Embodiment 11

[0067] Using the fuel gas of Example 1, instead of detecting with a nose, the same experiment as in Examples 1 to 10 was performed by placing pH test paper wetted with water. The pH test paper before the experiment starts is yellow. After leaving for 30 minutes, the change of color was confirmed, and the pH test paper changed to blue which shows alkalinity. It was shown that the odorant of the present invention has the characteristic of being detectable by methods other than odor.

Embodiment 12

[0069] An anion exchange resin binder (manufactured by Tokuyama Co., Ltd.) and a carbon-supported platinum catalyst (manufactured by Tanaka Precious Metals Co., Ltd.) were coated on both sides of the center of an 8 cm square anion exchange membrane (manufactured by Tokuyama Co., Ltd.) in a square of 2.3 cm. mixture to produce a membrane electrode assembly. The catalyst portion was sandwiched between two 2.3 cm square carbon porous plates (manufactured by SGL Co., Ltd.) with a thickness of about 200 μm, and installed in a commercially available fuel cell (manufactured by NF Circuit Design Co., Ltd.). The fuel gas of Example 1 was supplied to the anode side at 50° C. at 50 ml / min. Air humidified to a humidity of 100% was supplied to the cathode side at 50°C. The battery temperature was set to 50°C. Connect to an electronic load device (manufactured by NF Circuit Design Co., Ltd.), and record the current density value after 2 hours of power generation at a battery voltage of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com