A kind of preparation method of nanoscale silicon negative electrode of lithium ion battery

A lithium-ion battery, nano-scale technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of no discovery, low carbon residue rate, etc., and achieve the effects of improving cycle efficiency, simple polymerization method, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

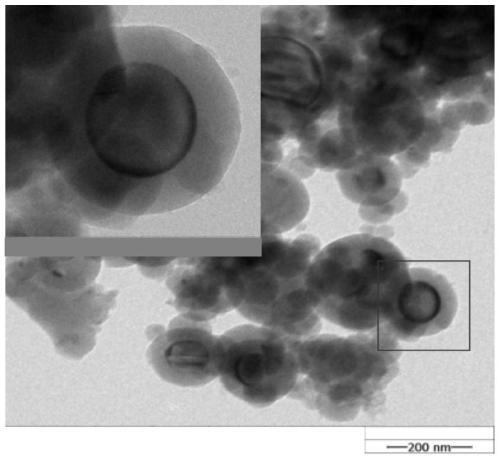

Image

Examples

Embodiment 1

[0027] 1) At room temperature, put 1 g of nano-silicon spheres into 100 ml of a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 and stir for 2 hours, then centrifuge and wash and separate 3 times to obtain the hydrophilic-treated nano-silicon spheres with hydroxyl groups on the surface. Silicon ball;

[0028] 2) Ultrasonically disperse 1 g of silicon spheres obtained in step 1) into 7 ml of 28% ammonia water and 100 ml of ethanol mixture, and dissolve 1 g of (2-bromo-2-methyl)hexyl trimethoxypropionate in a water bath at 40°C A mixed solution of silane and 10ml of ethanol was added dropwise to the suspension of silicon spheres, and the reaction was continued for 24 hours after the addition was completed, and the product was centrifuged three times with ethanol to obtain silicon spheres with groups on the surface that could initiate atom transfer radical polymerization;

[0029] 3) Mix 1 g of silicon spheres obtained in step 2) acco...

Embodiment 2

[0033] 1) At room temperature, place 1g of nano-silicon spheres under 100w ultraviolet light for 1 hour to obtain nano-silicon spheres with hydroxyl groups on the surface;

[0034] 2) Ultrasonically disperse 1 g of silicon spheres obtained in step 1) into 14 ml of 28% ammonia water and 180 ml of ethanol mixture, and dissolve 2 g of (2-bromo-2-methyl)hexyl trimethoxypropionate in a water bath at 60°C A mixed solution of silane and 20ml of ethanol was added dropwise to the suspension of silicon spheres, and the reaction was continued for 12 hours after the addition was completed, and the product was centrifuged three times with ethanol to obtain silicon spheres with groups on the surface that could initiate atom transfer radical polymerization;

[0035] 3) Mix 1 g of silicon spheres obtained in step 2) according to the ratio of initiator: methyl methacrylate: cuprous bromide: bipyridine in the ratio of 1:300:1:3, and initiate at 70°C under the condition of isolated air The monom...

Embodiment 3

[0039] 1) At room temperature, put 1 g of nano-silicon spheres into 100 ml of a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 and stir for 2 hours, then centrifuge and wash and separate 3 times to obtain the hydrophilic-treated nano-silicon spheres with hydroxyl groups on the surface. Silicon ball;

[0040] 2) Put the silicon ball obtained in step 1) into 1g, 10mL SOCl 2 ,10mL CHCl 3 , Stirred and refluxed for 36 hours, distilled off the unreacted solution, and obtained chlorinated silicon balls after vacuum drying. 1 g of chlorinated silica spheres, 15 mL of 1,4-dioxane, 3 mL of tert-butyl hydroperoxide (TBHP), 0.05 g of NaHCO 3 Mix, react under nitrogen protection at room temperature for 12 hours, centrifuge, wash with methanol, and dry in vacuum to obtain silicon spheres whose surface contains groups that can initiate oxygen and nitrogen free radicals to regulate polymerization;

[0041] 3) Add 1 g of silicon spheres obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com